A control method for finished product stacking of finishing line

A control method and stacking technology, which is applied in the stacking of objects, conveyor control devices, loading/unloading, etc., can solve the problem of uneven length and direction of bales, inability to ensure the stacking shape of bales, and large impact on equipment, etc. problems, to achieve the effect of avoiding out-of-tolerance stacking, ensuring the stacking shape of bales, and reducing direct impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Such as Figure 5 Shown, the control flow of the present invention is as follows:

[0040] 1) start

[0041] 2) Preparation for production

[0042] 3) The operation line starts

[0043] 4) Export speed signal upload control system

[0044] 5) Detect the position signal of the steel plate, and the control system calculates the delay time T and the beating time t

[0045] 6) Horseshoe roller flipping

[0046] 7) Movable baffle flapping

[0047] 8) end

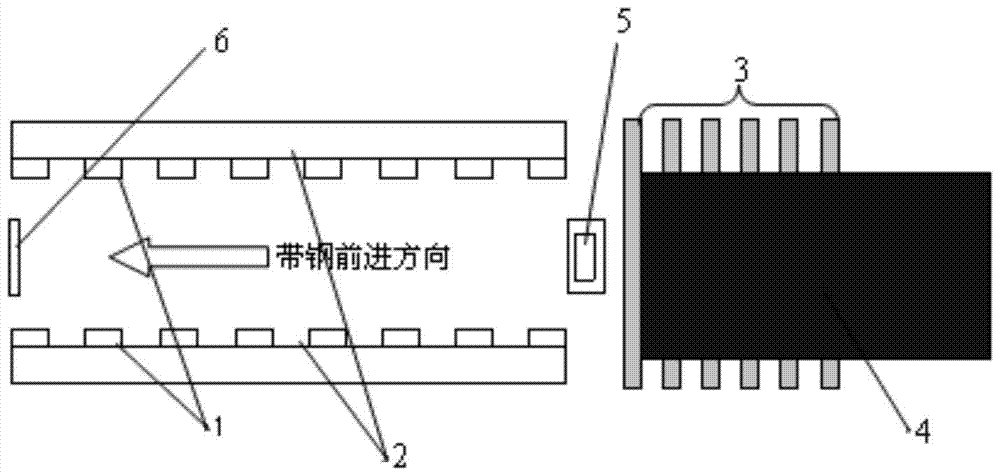

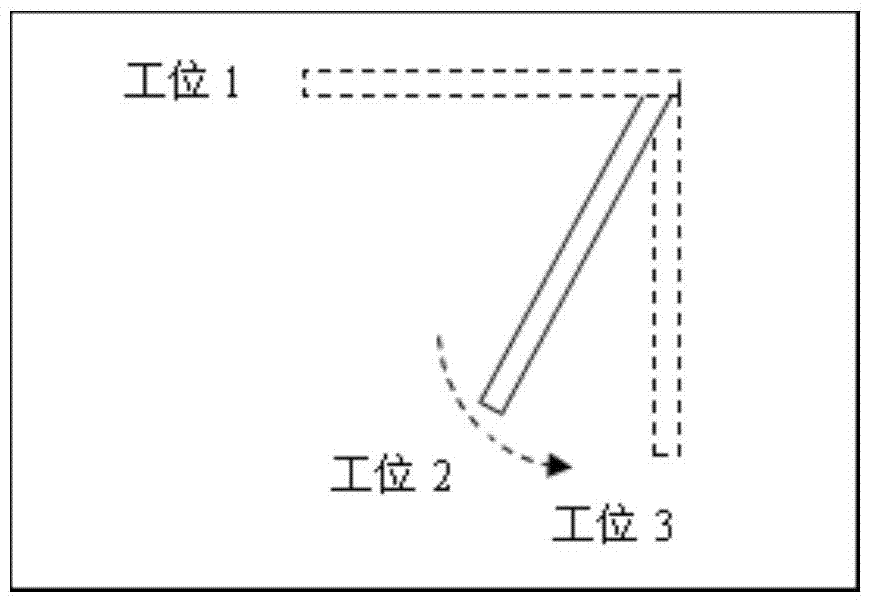

[0048] Such as figure 1 and image 3 As shown, the steel plate 4 is run by the conveying roller table 3 through the advancing direction of the strip steel. An induction grating 7 for detecting the position of the steel plate is arranged near the entrance of the movable baffle; when the induction grating 7 senses the steel plate 4, after the system delays for a certain time T according to the speed, the horseshoe roller 1 starts to turn downwards, and the steel plate 4 put down, and movable baffle 6 is patted. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com