Manufacturing method for large driving wheel forged pieces

A manufacturing method and driving wheel technology, applied in the field of forging technology, can solve the problems of unsuitability for mass production, low material utilization rate, unstable quality, etc., and achieve the effects of good consistency, high material utilization rate, and significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

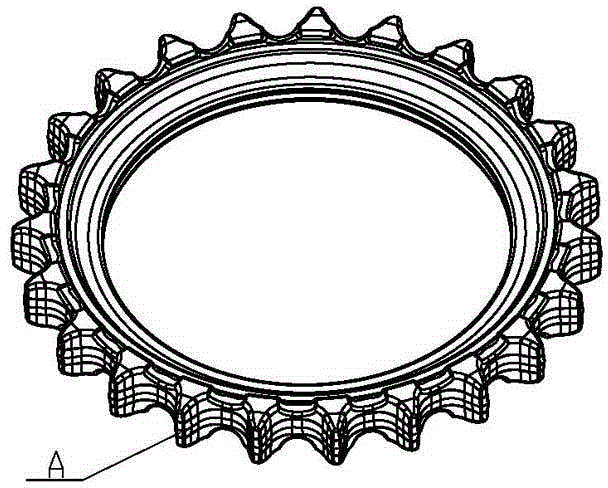

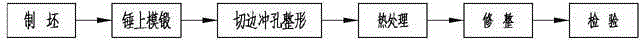

[0019] The present invention will be further described below in conjunction with the accompanying drawings. This example image 3 Shown: a manufacturing method of a large drive wheel forging, including: billet making process, hammer die forging process, edge trimming, punching and shaping process, heat treatment process, trimming process, and inspection process.

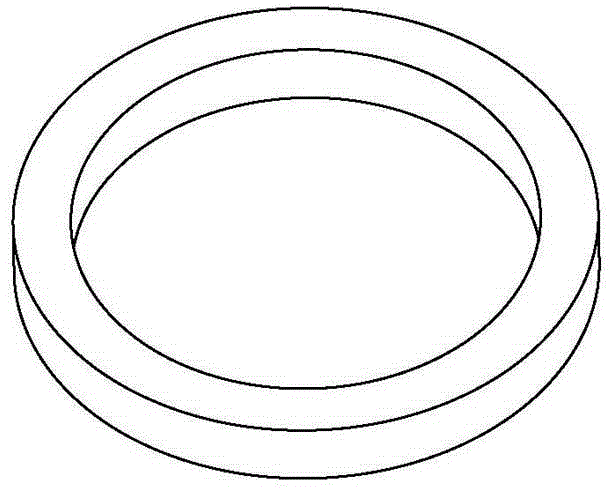

[0020] The billet making process includes: blanking by sawing machine or high-speed band saw, heating by electric furnace or gas furnace, making billet on ring rolling machine, heating the raw materials to 1100~1150°C on gas furnace or electric furnace, and then using air Forging equipment such as hammer or electro-hydraulic hammer flattens the billet, and uses a punch to punch a Φ70~Φ90mm hole in the middle of the billet, and after rounding, put it on the ring rolling machine to expand the hole to make a ring-shaped intermediate billet (see figure 2 ), complete the billet making process.

[0021] The hammer upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com