Preparation method of silver/carbon composite hollow nanospheres

A hollow nano-carbon composite technology, which is applied in the preparation of microspheres, microcapsule preparations, etc., to achieve the effect of improving utilization efficiency, uniform size distribution, and exquisite design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

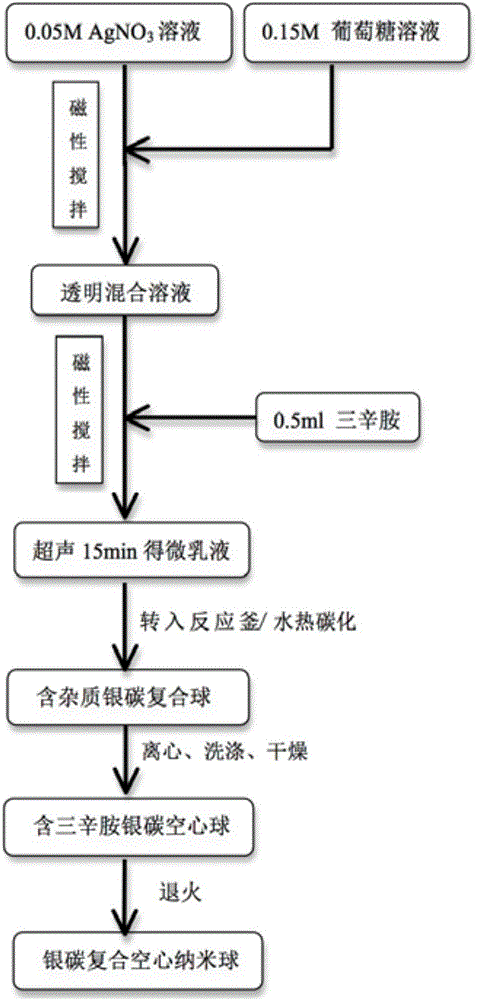

Method used

Image

Examples

Embodiment 1

[0017] The first step: configure 0.025M silver nitrate solution and 0.25M glucose aqueous solution respectively;

[0018] Step 2: Take 30ml of the above solutions and mix them under magnetic stirring;

[0019] Step 3: Slowly add 0.5ml trioctylamine dropwise to the above mixed solution while stirring;

[0020] Step 4: Put the above solution into an ultrasonic cleaner for 15 minutes;

[0021] Step 5: Quickly transfer the above suspension to a 100ml polytetrafluoroethylene-lined stainless steel reaction kettle, and react at 180°C for 12h;

[0022] Step 6: After the reaction kettle is naturally cooled to room temperature, the reaction solution is centrifuged to obtain black solid particles;

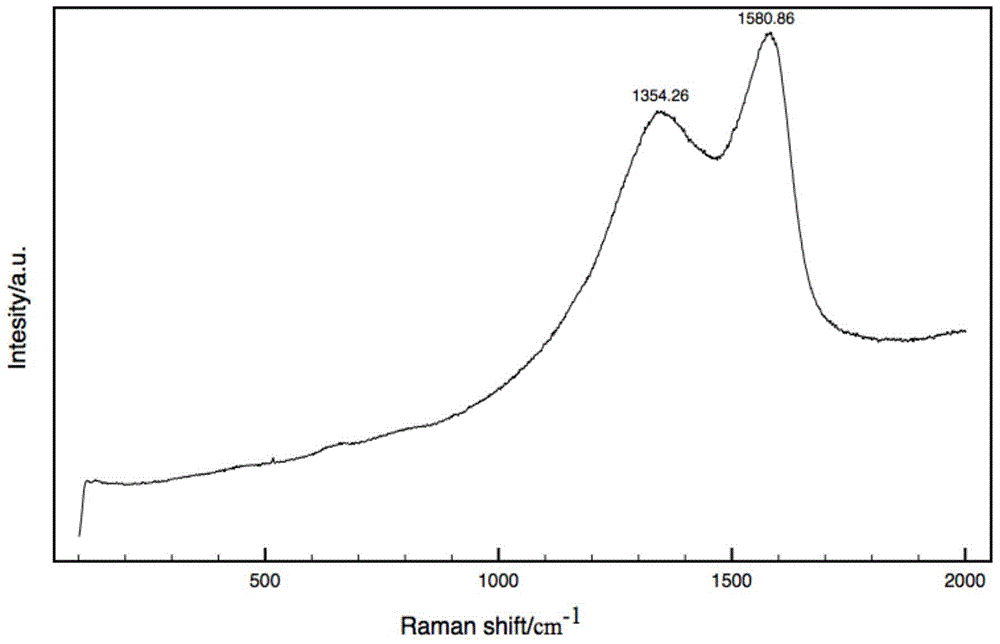

[0023] Step 7: Alternately and repeatedly wash the precipitate with water and absolute ethanol 3 times each, and vacuum dry at 60°C for 10 hours to obtain hollow nanospheres; figure 2 In order to characterize the structure of the obtained silver / carbon composite hollow nanospheres, the Ra...

Embodiment 2

[0025] The first step: configure 0.025M silver nitrate solution and 0.25M glucose aqueous solution respectively;

[0026] Step 2: Take 30ml of the above solutions and mix them under magnetic stirring;

[0027] Step 3: Slowly add 0.5ml trioctylamine dropwise to the above mixed solution while stirring;

[0028] Step 4: Put the above solution into an ultrasonic cleaner for 15 minutes;

[0029] Step 5: quickly transfer the above suspension to a polytetrafluoroethylene-lined stainless steel reactor (total volume is 100ml), and react at 180°C for 10h;

[0030] Step 6: After the reaction kettle is naturally cooled to room temperature, the reaction solution is centrifuged to obtain black solid particles;

[0031] Step 7: alternately and repeatedly wash the precipitate with water and absolute ethanol for 3 times, and vacuum-dry at 60°C for 10 hours to obtain hollow nanospheres;

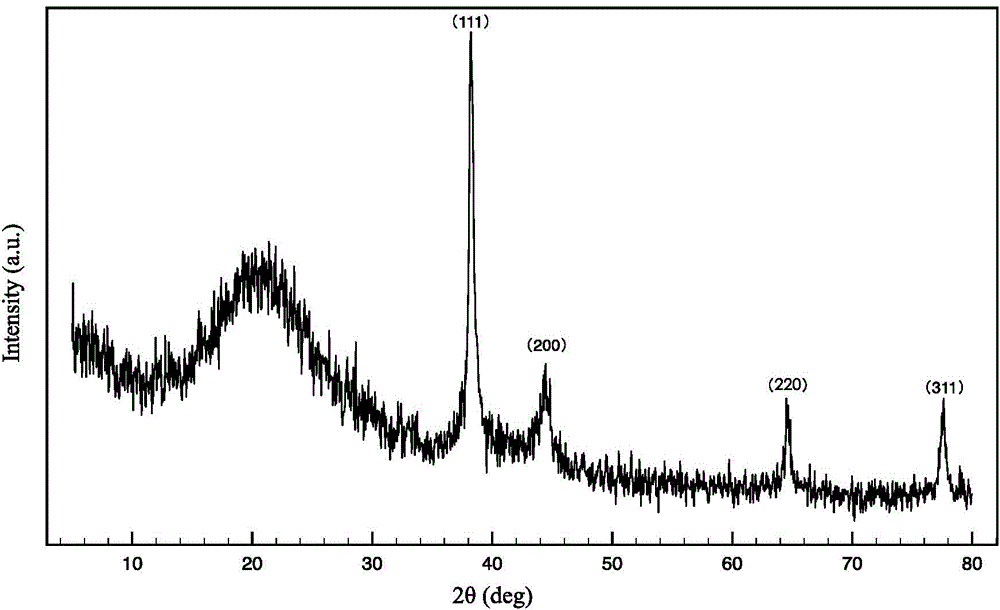

[0032] attached image 3 The XRD spectrum is the structural characterization of the obtained silver / car...

Embodiment 3

[0035] The first step: configure 0.025M silver nitrate solution and 0.50M glucose aqueous solution respectively;

[0036] Step 2: Take 30ml of the above solutions and mix them under magnetic stirring;

[0037] Step 3: Slowly add 0.75ml trioctylamine dropwise while stirring in the above mixed solution;

[0038] Step 4: Put the above solution into an ultrasonic cleaner for 15 minutes;

[0039] Step 5: Quickly transfer the above suspension to a polytetrafluoroethylene-lined stainless steel reactor (total volume is 100ml), and react at 180°C for 20h;

[0040] Step 6: After the reaction kettle is naturally cooled to room temperature, the reaction solution is centrifuged to obtain black solid particles;

[0041] Step 7: Alternately and repeatedly wash the precipitate with water and absolute ethanol for 3 times, and vacuum-dry at 60°C for 10 hours to obtain silver-carbon composite nano hollow spheres;

[0042] Step 8: The product is annealed at 500° C. at a heating rate of 10° C. / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com