Sterilization system and method of electric heating water dispenser

A technology of sterilization system and water dispenser, which is applied in the direction of heating, beverage preparation devices, household appliances, etc., can solve the problem that the total number of bacterial colonies in electric water dispensers exceeds the standard, and achieve the effects of convenient operation, resource saving, and lower sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

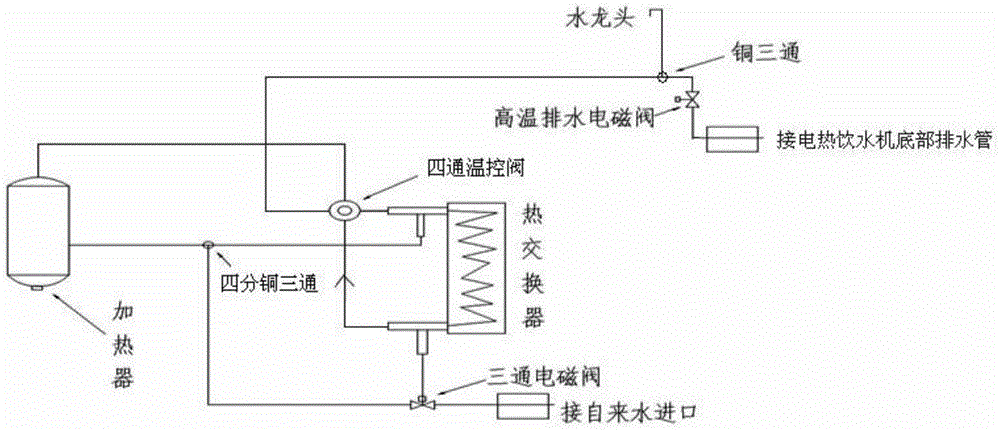

[0023] A kind of sterilization system of electric heating water dispenser provided in this embodiment, such as figure 1 As shown, the sterilization system is set inside the electric water dispenser, including a heat exchanger, a heating tank and several water pipes. The heat exchanger is composed of an inner pipe and an outer pipe sleeved on the inner pipe. The inlet and outlet of the inner pipe are reversely set. A 12V three-way solenoid valve is installed at the water inlet of the heat exchanger outer pipe. The water inlet of the three-way battery valve is connected to the tap water pipe externally. Connect the water inlet of the outer pipe of the heat exchanger, and the outlet of the outer pipe of the heat exchanger is connected to the heating water tank through the water pipe. The other water outlet of the battery valve is connected to the four-point copper tee through a water pipe, and the heated water bladder is connected to the water inlet of the inner tube of the heat ...

Embodiment 2

[0025] This embodiment provides a sterilization method for the sterilization system of the electric heating water dispenser in the embodiment, which specifically includes the following steps:

[0026] (1) In the normal working state of the electric water dispenser, the three-way battery valve and the four-point copper three-way in front of the heater are closed, and the three-way solenoid valve is connected to the water inlet of the outer tube of the heat exchanger, so that the external cold tap water passes through The outer tube of the heat exchanger enters the heater to be heated, and the heated tap water is connected to the water inlet of the inner tube of the heat exchanger through the four-way temperature control valve, so as to keep the flow direction of the hot tap water and the cold tap water in the opposite direction, and the hot tap water passes through the hot tap water. The inner pipe of the exchanger drains to the tap for drinking;

[0027] (2) When the water pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com