A high-barrier non-metallic diaphragm pressure reducer

A non-metallic, diaphragm-type technology, applied in the direction of safety valves, engine components, balance valves, etc., can solve the problems of poor sealing margin of external leakage, failure to meet the high reliability and high precision of spacecraft, and achieve the reduction of processing accuracy requirements , Improve the anti-pollution ability, the effect of small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

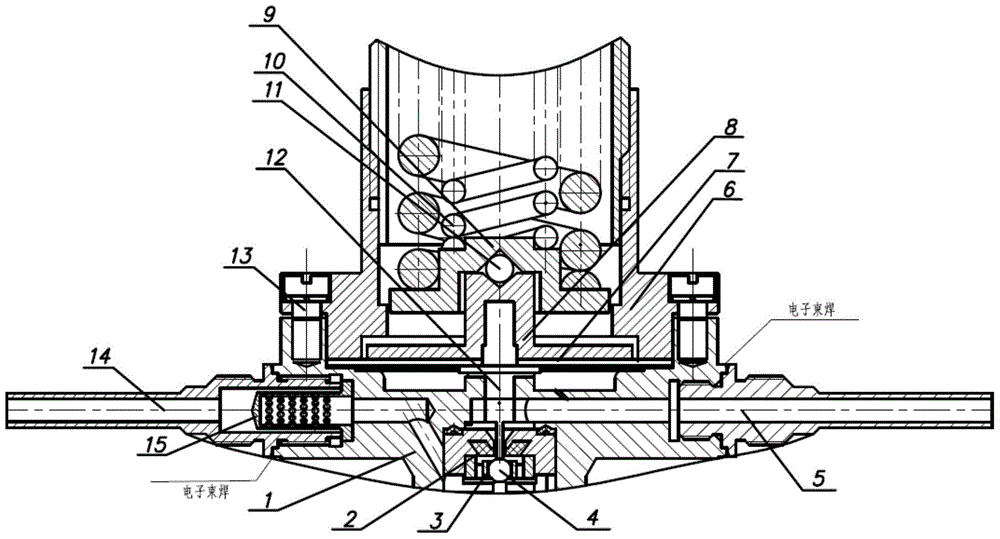

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as figure 1 As shown, a high-barrier non-metallic diaphragm pressure reducer includes a valve body 1, a valve seat 2, a guide pair 3, a valve steel ball 4, an outlet nozzle 5, a connecting pressure ring 6, a non-metallic diaphragm 7, Pressure plate 8, spring seat 9, spring 10, adjusting steel ball 11, kinematic pair 12, screw 13, inlet nozzle 14 and filter assembly 15;

[0026] The upper end of the pressure plate 8 has a groove; the spring seat 9 has a groove matching the groove of the pressure plate 8;

[0027] The valve seat 2 is made of internal hot-pressed non-metallic F3, and the valve steel ball 4 is made of grade G5 steel ball, and the material is stainless steel;

[0028] With the valve body 1 as the base, the valve seat 2 is fixedly placed in the high-pressure chamber of the valve body 1;

[0029] The guide pair 3 is fixedly placed in the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com