Low-channel progressive construction tunnel entrance method of subway mined tunnel

A progressive, low-passage technology, applied in tunnels, mining equipment, earth-moving drilling, etc., can solve the problems of increasing the undisturbed underground rock and soil disturbance, increasing the internal force of the secondary lining structure, and shallowing the buried depth of the construction channel. Simple and fast operation, reduce internal force, reduce the effect of vertical height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

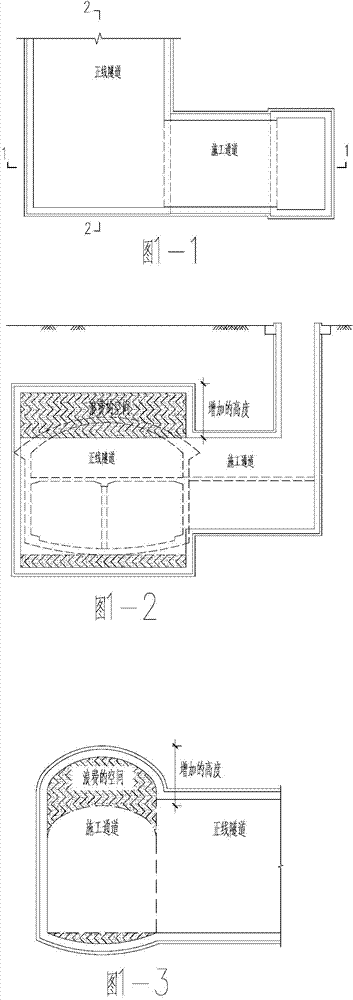

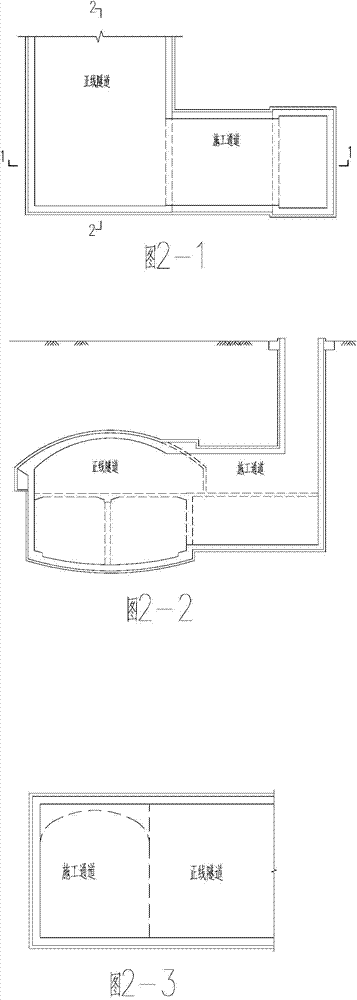

[0026] see Figure 2 ~ Figure 6 Shown: a kind of underground excavation tunnel low-passage progressive hole method, it comprises the following steps:

[0027] ① First, determine the structural outline of the construction tunnel according to the functional requirements, and combine the structural outline dimensions of the main line tunnel, and make a progressive portal frame 1 with gradual changes in height according to the construction steps;

[0028] ②From the construction tunnel to the direction perpendicular to the main line tunnel, along the effective main line tunnel structure outline, gradually expand and excavate (without elevated sections); every step of excavation should be set in time with progressive portal frame 1 until this part is completed excavation and support;

[0029] ③In the progressive gantry, construct a supporting and supporting gantry 2 of the main line tunnel along the outline of the main line tunnel to support the progressive gantry set perpendicular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com