Mobile concrete mixing plant and batching machine thereof

A batching machine and concrete technology, which is applied in mixing plants, mixing operation control, clay preparation devices, etc., can solve the problems of long transfer transportation period, high transportation cost of batching machine transfer, complicated transportation process, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

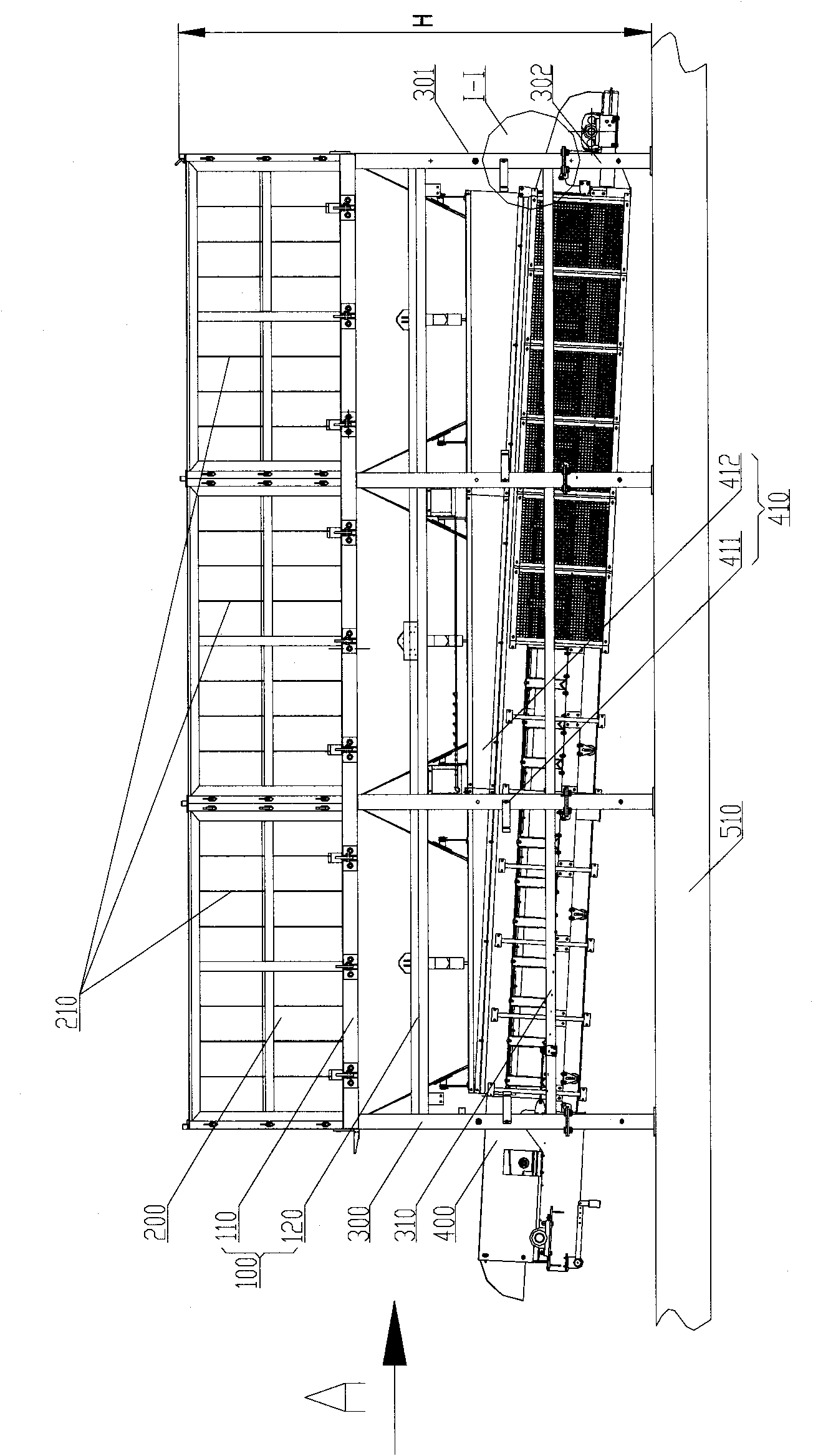

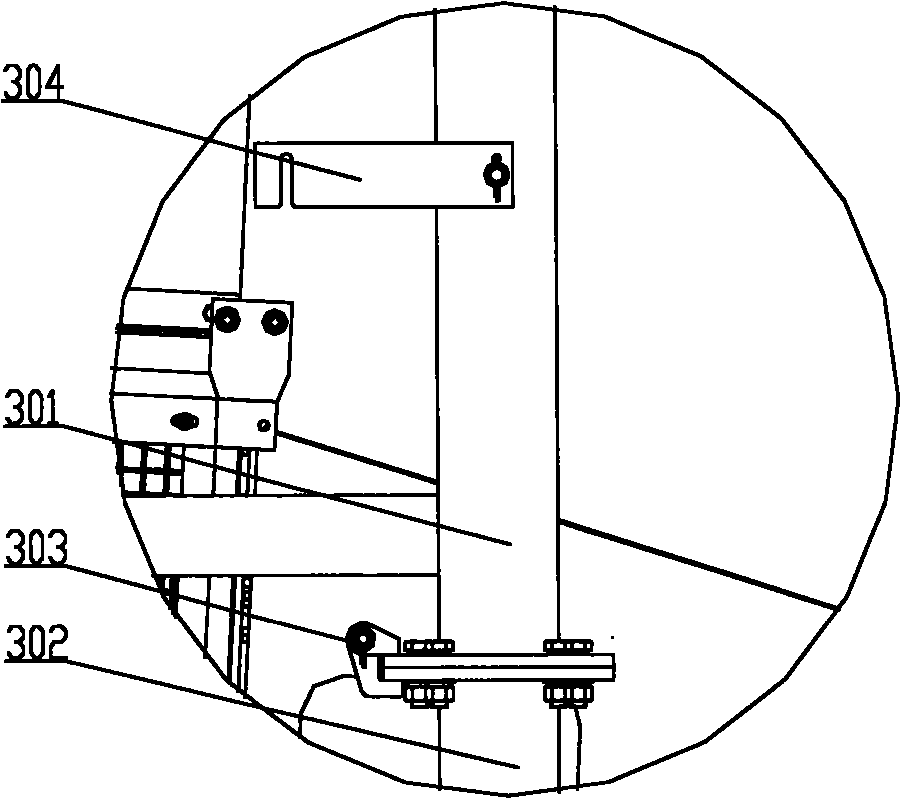

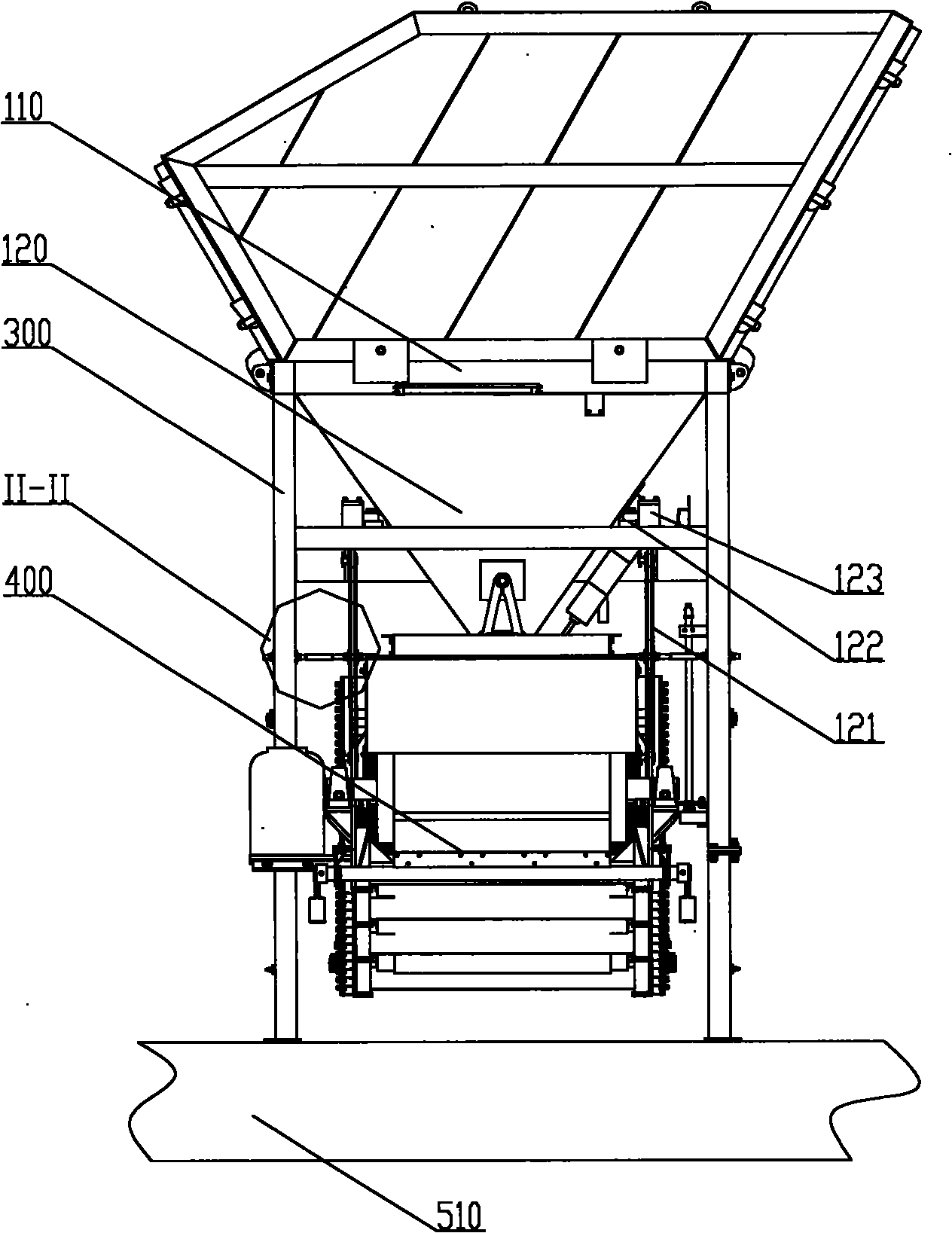

[0040] Please refer to figure 1 , figure 1 Provide the present invention with a schematic diagram of the side structure of the batching machine in working condition. The working state is the state when the mobile concrete batching plant is preparing concrete at a predetermined position and the batching machine is supplying aggregate to the mixer.

[0041] The batching machine includes a batching machine main body 100 , a material storage box 200 , legs 300 and a conveyor 400 . The batching machine main body 100 has an upper bracket 110 and a lower bracket 120 .

[0042] The material storage box 200 provides a predetermined space for storing aggregates. In the working state, the material storage box 200 is at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com