Control method for preventing nitrogen increasing in LF refining treatment

A control method and technology before treatment, which are applied in the field of LF furnace refining process, can solve the problems of inability to submerged arc heating, improper atmosphere control, and neglect of furnace cover atmosphere.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

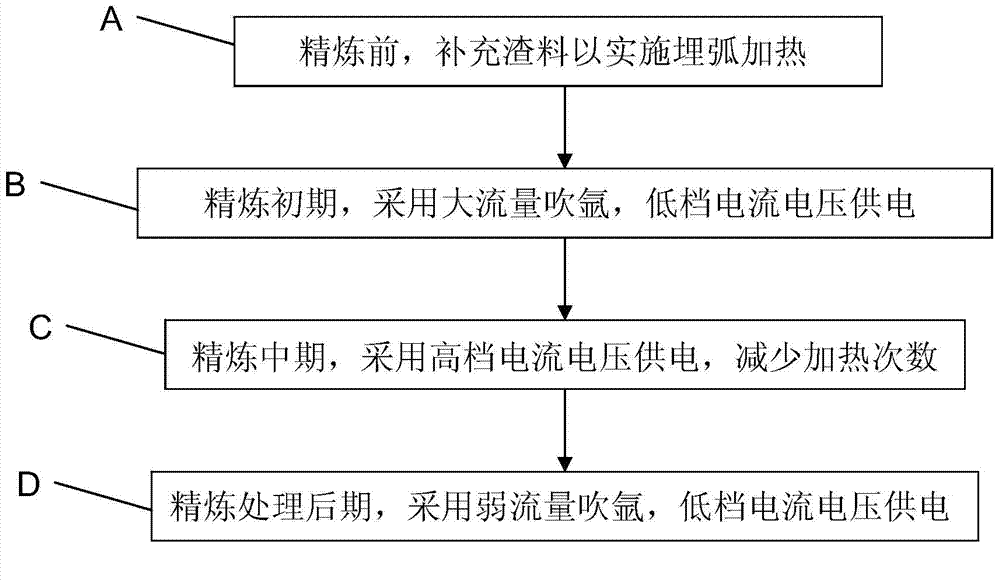

[0039] see figure 1 Shown, the control method that prevents nitrogen increase in the LF furnace refining treatment of the present invention mainly comprises the following steps:

[0040] A. Submerged arc heating is implemented by replenishing slag before refining treatment. That is to say, when the molten steel is not electrified, it is first necessary to add a batch of slag to cover the molten steel.

[0041] This is because the slag blocking operation has been carried out during the tapping process of the converter, and the slag volume of the converter is controlled below 50mm. Since the molten steel is not in contact with the atmosphere, the thermodynamic and kinetic conditions for the nitrogen absorption of the molten steel are insufficient, and the slag can prevent Nitrogen absorption by molten steel. If molten steel en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com