A kind of preparation method of simple theaflavin monomer

A technology of theaflavins and monomers, which is applied in the field of preparation of simple theaflavin monomers, can solve the problems of decreased physiological activity, precipitation, low solubility of ester-type theaflavins, etc., and achieves the effect of low adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

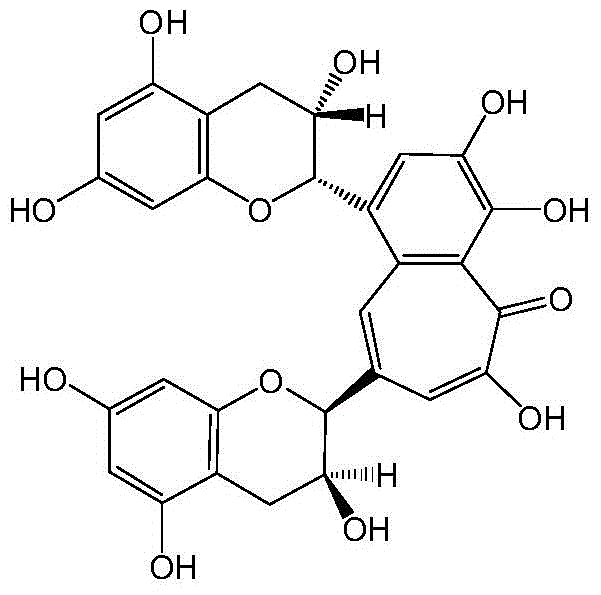

Image

Examples

Embodiment 1

[0023] 1. Take 10 grams of 40% theaflavin extract, make 500ml theaflavin solution, add 80mg tannase and 20mg pectinase to the solution, stir at 25°C for 30 minutes for enzymolysis, and obtain enzyme Solution.

[0024] 2. Rapidly raise the temperature of the enzymolysis solution to 90°C and keep it for 5 minutes. After the enzymolysis solution cools down to room temperature, centrifuge at 8000r / min for 10min, take the supernatant and filter it.

[0025] 3. Slowly pass the supernatant filtered in step 2 through the chromatographic column equipped with DM130 adsorption resin, and elute with 10%, 30%, and 50% ethanol aqueous solution respectively, and collect 50% ethanol eluate, And the eluate was concentrated to 16-18 Baume degrees to obtain a concentrated solution.

[0026] 4. Put the concentrated solution at 0-4° C. for 48 hours, add a small amount of theaflavin monomer to crystallize the concentrated solution, then centrifuge and dry to obtain 2.13 g of simple theaflavins. A...

Embodiment 2

[0029] 1. Take 10 grams of 60% theaflavin extract and make 1000ml theaflavin solution, add 90mg tannase and 15mg pectinase to the solution, stir at 28°C for 40 minutes for enzymolysis to obtain enzyme Solution.

[0030] 2. Rapidly raise the temperature of the enzymolysis solution to 85° and keep it for 10 minutes. After the enzymolysis solution cools down to room temperature, centrifuge at 8000r / min for 15min, take the supernatant and filter it.

[0031] 3. The filtered supernatant in step 2 is passed through a chromatographic column equipped with D140 adsorption resin, and is eluted with 20%, 40%, and 60% ethanol aqueous solution respectively, and 60% ethanol eluent is collected, and the The eluent was concentrated to 16-18 degrees Baume to obtain a concentrated solution.

[0032] 4. Put the concentrated solution at 0-4° C. for 60 hours, add a small amount of theaflavin monomer to crystallize the concentrated solution, then centrifuge and dry to obtain 3.25 g of simple theaf...

Embodiment 3

[0034] 1. Take 10 grams of 80% theaflavin extract, make 1000ml theaflavin solution, add 100mg tannase and 20mg pectinase to the solution, stir at 30°C for 50 minutes for enzymolysis, and obtain enzyme Solution.

[0035] 2. Rapidly raise the temperature of the enzymolysis solution to 90° and keep it for 5 minutes. After the enzymolysis solution cools down to room temperature, centrifuge at 10000r / min for 20min, take the supernatant and filter it.

[0036] 3. Slowly pass the filtered supernatant in step 2 through the chromatographic column equipped with D140 adsorption resin, and elute with 20%, 40%, and 60% ethanol aqueous solution respectively, and collect 60% ethanol eluate, The eluent was concentrated to 16-18 degrees Baume to obtain a concentrated solution.

[0037] 4. Put the concentrated solution at a temperature of 0-4° C. for 72 hours, add a small amount of theaflavin monomer to crystallize the concentrated solution, then centrifuge and dry to obtain 4.39 g of simple t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com