Concrete monolithic and segmental prefabricated biogas digesters and their multifunctional settings

A biogas digester and multi-functional technology, applied in the direction of gas production bioreactors, waste fuels, etc., can solve the problems of difficult slag removal, extensive management, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

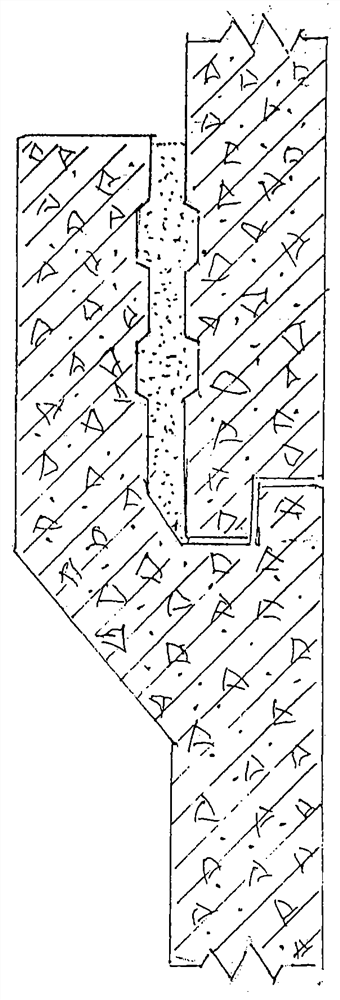

[0026] Fifth, the specific implementation method: (the following is the use process of 1-5 structure diagram for further explanation)

[0027] Coarse materials (rods) in ( figure 1 ) hydrolysis in the acidification tank, acidification → feed liquid passes through the slag retaining mesh to the valve, feed inlet, feed pipe, enters the fermentation room, fine material (feces) is directly added to the feed inlet → close the water pressure room and pass through the discharge Pipe valve (water retention level) → open the discharge valve ( figure 2 For the ①scum discharge valve and ②sediment discharge valve, a buoy is installed in the discharge pipe and a pressure gauge is installed in the gas storage room for short-term slag discharge, and the double-controlled internal storage liquid level keeps the balance of the incoming and outgoing materials, which is very good for slagging. Advantageously, the bottom of the pool is better than the land where the fertilizer is used. This is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com