A kind of efficient and environment-friendly method for producing washing powder from 4a zeolite slurry

A technology of washing powder and zeolite, which is applied in the direction of A-type crystalline aluminosilicate zeolite, chemical instruments and methods, crystalline aluminosilicate zeolite, etc., can solve the problem of increasing the cost of spray drying and waste of resources, endangering the health of operators, and difficult Uniform mixing and other issues to achieve the effect of increasing solid capacity, saving resources and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

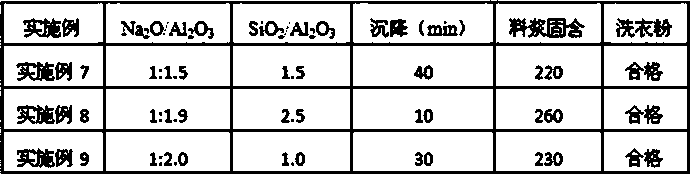

Examples

Embodiment 1

[0026] Preparation of Part1 Sodium Aluminate Solution

[0027] Take industrial aluminum hydroxide, add 32% NaOH solution, make Na in the solution 2 O and Al 2 o 3 The molar ratio is 1:1.0, and mixed evenly, under the condition of full stirring, it is dissolved by heating with steam. After the dissolution is completed, it is prepared with distilled water, so that the Al in the solution 2 o 3 The concentration is 100g / L.

[0028] Preparation of Part2 liquid water glass

[0029] Add the solid water glass with a modulus of 2.9 into distilled water, heat and dissolve in the reaction kettle with steam, prepare with distilled water, and filter to obtain SiO 2 A qualified liquid water glass solution with a concentration of 18%.

[0030] Preparation of Part3 4A Zeolite Molecular Sieve

[0031] Mix the sodium aluminate prepared by part1 and the liquid water glass prepared by part2 according to the ratio of normal 4A zeolite production, so that the SiO in the mixed slurry 2 / Al ...

Embodiment 2

[0038] Preparation of Part1 Sodium Aluminate Solution

[0039] Take industrial aluminum hydroxide, add NaOH crystals and water to make Na in the solution 2 O and Al 2 o 3 The molar ratio is 1:1.2, and mixed evenly; under the condition of stirring, it is dissolved by heating with steam. After the dissolution is completed, it is prepared with distilled water so that the Al in the solution 2 o 3 The concentration is 80 g / l.

[0040] Preparation of Part2 liquid water glass

[0041] Add the solid water glass with a modulus of 2.7 into distilled water, heat and dissolve it with steam in the reactor, prepare it with distilled water, and filter to obtain SiO 2 A qualified liquid water glass solution with a concentration of 16%.

[0042] Preparation of Part3 4A Zeolite Molecular Sieve

[0043] Mix the sodium aluminate prepared by part1 and the liquid water glass prepared by part2 according to the proportion produced by normal 4A zeolite, so that the SiO in the mixed slurry 2 / A...

Embodiment 3

[0050] Preparation of Part1 Sodium Aluminate Solution

[0051] Take industrial aluminum hydroxide, add NaOH and water to make Na in the solution 2 O and Al 2 o 3 The molar ratio is 1:1.4, and mixed evenly, under the condition of full stirring, it is dissolved by heating with steam. After the dissolution is completed, it is prepared with distilled water, so that the Al in the solution 2 o 3 The concentration is 105g / L.

[0052] Preparation of Part2 liquid water glass

[0053] Add the solid water glass with a modulus of 2.5 into distilled water, heat and dissolve in the reaction kettle with steam, prepare with distilled water, and filter to obtain SiO 2 A qualified liquid water glass solution with a concentration of 20%.

[0054] Preparation of Part3 4A Zeolite Molecular Sieve

[0055] Mix the sodium aluminate prepared by part1 and the liquid water glass prepared by part2 according to the ratio of normal 4A zeolite production, so that the SiO in the mixed slurry 2 / Al 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| foam | aaaaa | aaaaa |

| foam | aaaaa | aaaaa |

| foam | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com