A kind of preparation method of green caserin hydrochloride hemihydrate crystal form

A green caserin hydrochloride, hemihydrate technology, applied in the direction of organic chemistry, can solve the problems of reducing the optical purity of the product and affecting the quality of the finished product, and achieve the effect of recyclable solvent, simple preparation method and high optical purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

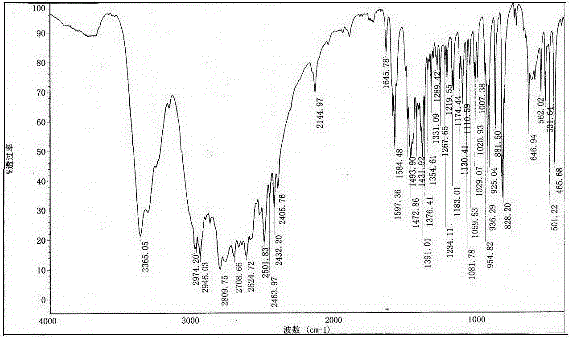

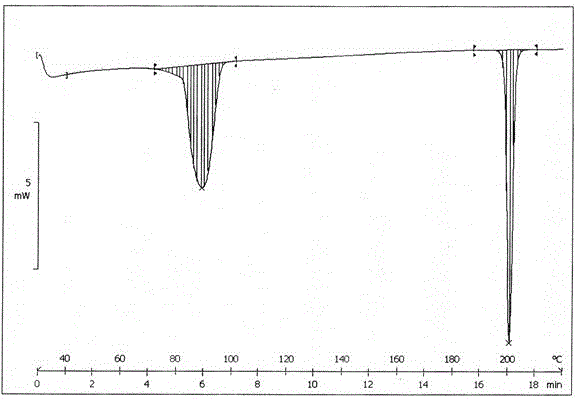

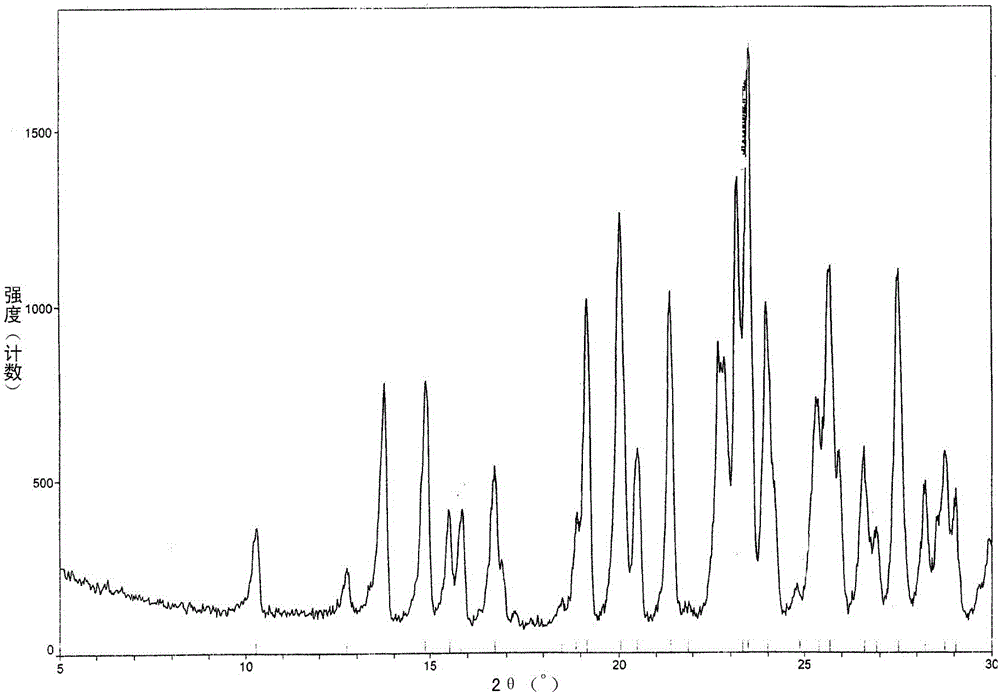

Image

Examples

Embodiment 1

[0022] (a) Preparation of green caserin hydrochloride

[0023] Add 100 mL of dichloromethane (moisture content: 0.1%) to 10.0 g (0.05 mol) of green caserin free base at 0-5 °C, stir until it is clear and completely dissolved, then slowly inject dry hydrogen chloride into the reaction solution After the gas was saturated, dichloromethane was distilled off under reduced pressure at 25°C to obtain 11.5 g of off-white powdery greencaserin hydrochloride solid, with a yield of 97.0%.

[0024] (b) Preparation of green caserin hydrochloride hemihydrate crystal form

[0025] (1) Add 115 mL of dichloromethane (moisture 0.1%) to 11.5 g (0.05 mol) of green caserin hydrochloride at 25-30 °C, stir until clear and completely dissolved, then add 0.45 g (0.025 mol) ) distilled water, stirred for 1.5 hours, concentrated and removed the solvent by distillation under reduced pressure at 25°C to obtain viscous oil.

[0026](2) Cool the viscous oil to 0-5°C, add 173 mL of ethyl acetate dropwise t...

Embodiment 2

[0032] (a) Preparation of green caserin hydrochloride

[0033] Add 1500mL of isopropanol (0.2% water) to 100.0g (0.51mol) greencaserin free base at 0-5°C, stir until clear and completely dissolved, then slowly inject dry hydrogen chloride gas into the reaction solution After saturation, the isopropanol was distilled off under reduced pressure at 30°C to obtain 113.0 g of off-white powdery green caserin hydrochloride solid, with a yield of 95.0%.

[0034] (b) Preparation of green caserin hydrochloride hemihydrate crystal form

[0035] (1) Add 1700mL of isopropanol (0.2% water) to 113.0g (0.487mol) greencaserin hydrochloride at 25-30°C, stir until clear and completely dissolved, then add 5.0g (0.278mol) distilled water, stirred for 1.5 hours, concentrated and removed the solvent by distillation under reduced pressure at 30°C to obtain a viscous oil.

[0036] (2) Cool the viscous oil to 0-5°C, add 2260 mL of n-hexane dropwise to the oil while stirring, and continue stirring at ...

Embodiment 3

[0038] (a) Preparation of green caserin hydrochloride

[0039] Add 500mL of anhydrous methanol (moisture content: 0.1%) to 100.0g (0.51mol) green caserin free base at 0-5°C, stir until clear and completely dissolved, then slowly inject dry hydrogen chloride gas into the reaction solution After saturation, anhydrous methanol was evaporated under reduced pressure at 30°C to obtain 116.3 g of off-white powdery green caserin hydrochloride solid, with a yield of 98.0%.

[0040] (b) Preparation of green caserin hydrochloride hemihydrate crystal form

[0041] (1) Add 600mL of absolute ethanol (0.3% water) to 116.3g (0.5mol) of green caserin hydrochloride at 25-30°C, stir until clear and completely dissolved, then add 5.0g (0.278mol) distilled water, stirred for 1 hour, concentrated and removed the solvent by distillation under reduced pressure at 30°C to obtain a viscous oil.

[0042] (2) Cool the viscous oil to 0-5°C, add 1163 mL of acetone dropwise to the oil while stirring, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com