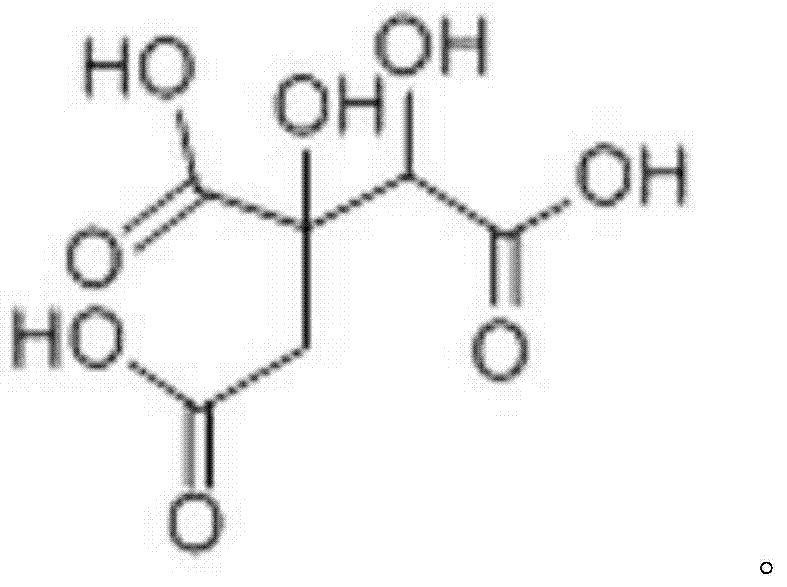

Method for preparing high-purity hydroxycitric acid with garcinia cambogia as raw material

A technology of hydroxycitric acid and calcium hydroxycitrate, which is applied in the field of preparing high-purity hydroxycitric acid, can solve problems such as difficult separation, non-biological activity, instability, etc., and achieves the stability of hydroxycitric acid, with simple and easy method and mild conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Garcinia cambogia powder 1kg, add 30L CaCO with a mass concentration of 2% 3 Add 10 grams of activated carbon to the solution, the extraction temperature is 30°C, the high-shear extraction is 20 minutes, the high-shear motor speed is 5800 rpm, and the filter is filtered to obtain 30L of calcium hydroxycitrate filtrate.

[0034] (2) Filter the filtrate through a microfiltration-ultrafiltration combined equipment, the microfiltration membrane operating temperature is 30°C, the flow rate is an average of 10L / min, the inlet pressure is 0.25MPa, the outlet pressure is 1.1MPa, and the pore size of the microfiltration membrane is 0.2 microns; The ultrafiltration membrane temperature is 30°C, the flow rate is 4L / min, the operating pressure is 0.8MPa, and the molecular weight cut-off of the ultrafiltration membrane is 50000 Daltons; 28L of high-purity calcium hydroxycitrate filtrate is obtained.

[0035] (3) Add 1.5mol / L of H to the high-purity calcium hydroxycitrate filtrate 3 PO...

Embodiment 2

[0039] (1) Garcinia cambogia powder 1kg, add 20L CaCO with a mass concentration of 3% 3 The solution is added with 15 grams of activated carbon, the extraction temperature is 35°C, the high-shear extraction is 20 minutes, the high-shear motor speed is 7000 rpm, and it is filtered to obtain 20L of calcium hydroxycitrate filtrate.

[0040] (2) Filter the filtrate through a combined microfiltration-ultrafiltration device. The operating temperature of the microfiltration membrane is 30°C, the average flow rate is 15L / min, the inlet pressure is 0.25MPa, the outlet pressure is 1.1MPa, and the pore size of the microfiltration membrane is 0.8 microns; The ultrafiltration membrane temperature is 30°C, the flow rate is 5L / min, the operating pressure is 0.8MPa, and the molecular weight cut-off of the ultrafiltration membrane is 5000 Daltons; 19.8L of high-purity calcium hydroxycitrate filtrate is obtained.

[0041] (3) Add 1mol / L of H to the high-purity calcium hydroxycitrate filtrate 3 PO 4 2...

Embodiment 3

[0045] (1) Garcinia cambogia powder 1kg, add 40L CaCO with a mass concentration of 1.5% 3 The solution is added with 20 grams of activated carbon, the extraction temperature is 35°C, the high-shear extraction is 30 minutes, the high-shear motor speed is 8000 rpm, and filtered to obtain 20L of calcium hydroxycitrate filtrate.

[0046] (2) Filter the filtrate through a combined microfiltration-ultrafiltration device. The operating temperature of the microfiltration membrane is 40℃, the average flow rate is 15L / min, the inlet pressure is 0.25MPa, the outlet pressure is 1.1MPa, and the pore size of the microfiltration membrane is 0.45 microns; The ultrafiltration membrane temperature is 40°C, the flow rate is 5.4L / min, the operating pressure is 0.8MPa, and the molecular weight cut-off of the ultrafiltration membrane is 20,000 Daltons; 36.5L of high-purity calcium hydroxycitrate filtrate is obtained.

[0047] (3) Add 1mol / L of H to the high-purity calcium hydroxycitrate filtrate 3 PO 4 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com