Low-shrinkage, low-viscosity and ultrahigh strength concrete

An ultra-high-strength concrete and low-viscosity technology, applied in the field of building materials, can solve the problems of difficult concrete technology, insufficient number of powder storage tanks, and separation from practical applications, etc., to achieve improved performance and mechanical properties, good work performance, and obvious increase effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

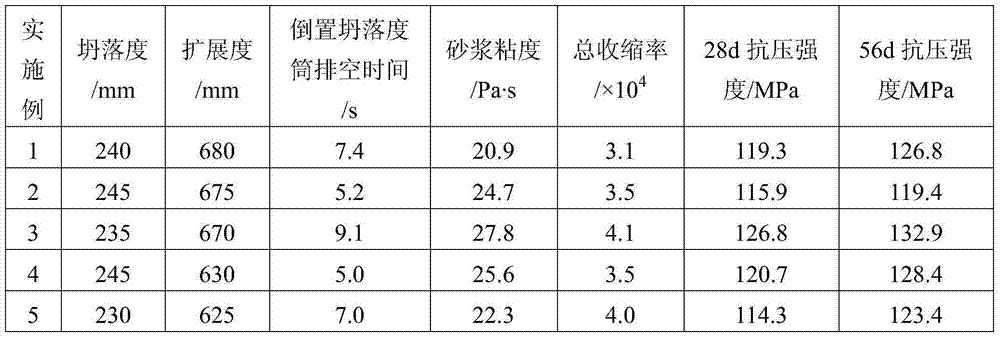

[0020] A low-shrinkage, low-viscosity ultra-high-strength concrete, one cubic meter (m 3 ) Concrete components are as follows: cement 250kg, microbeads 180kg, mineral powder 120kg, machine-made sand 820kg, basalt gravel 985kg, water reducing agent 9.0kg, water 125kg. After the materials are ready, mix the above components and stir them with a forced mixer for 1.5mim to get the low-shrinkage low-viscosity ultra-high-strength concrete described in the present invention. The concrete has good workability, low viscosity, and no segregation or bleeding. Phenomenon. The performance, hardening performance and shrinkage of the concrete mixture are shown in Table 1.

Embodiment 2

[0022] A low-shrinkage, low-viscosity ultra-high-strength concrete, one cubic meter (m 3 ) Concrete components are as follows: cement 280kg, microbeads 150kg, mineral powder 110kg, machine-made sand 840kg, basalt gravel 1000kg, water reducing agent 8.7kg, water 120kg. After the materials are fully prepared, mix the above components and stir them with a forced mixer for 1.5 minutes to obtain the low-shrinkage, low-viscosity, ultra-high-strength concrete described in the present invention. The concrete has good workability, low viscosity, and no segregation or bleeding. Phenomenon. The performance, hardening performance and shrinkage of the concrete mixture are shown in Table 1.

Embodiment 3

[0024] A low-shrinkage, low-viscosity ultra-high-strength concrete, one cubic meter (m 3 ) Concrete components are as follows: cement 300kg, microbeads 120kg, mineral powder 120kg, machine-made sand 860kg, limestone gravel 970kg, water reducing agent 10.2kg, water 120kg. After the materials are fully prepared, mix the above components and stir them with a forced mixer for 2.0 minutes to obtain the low-shrinkage, low-viscosity, ultra-high-strength concrete described in the present invention. The concrete has good workability, low viscosity, and no segregation or bleeding. Phenomenon. The performance, hardening performance and shrinkage of the concrete mixture are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com