A method and device for producing highly active mineral materials

A mineral material, high activity technology, applied in the field of material processing, to achieve wide application prospects, high activity coefficient, good appearance and color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

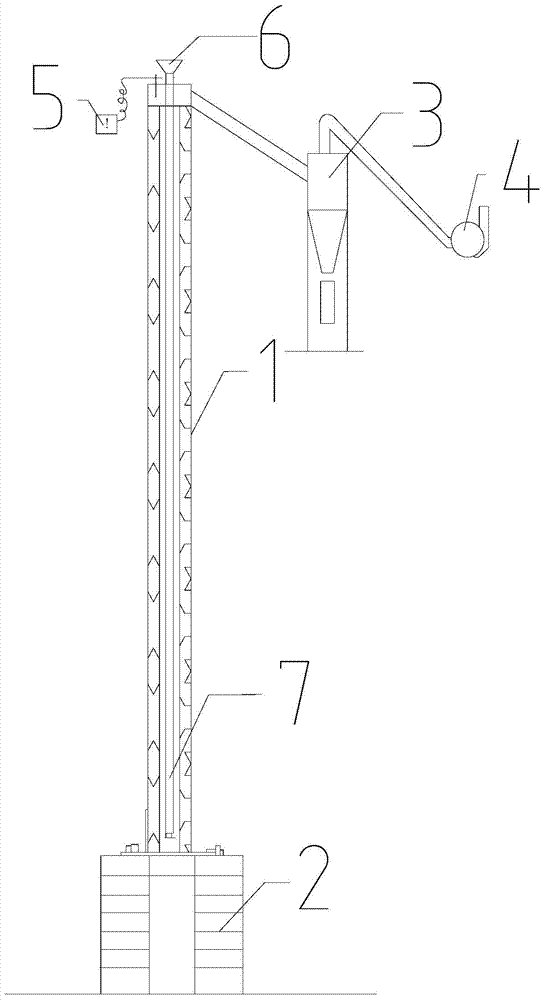

[0061] In order to verify the feasibility of the production process and facilities of the present invention, the applicant has specially built a test kiln. The structure of the test kiln is shown in figure 1 . The device for implementing the method for producing highly active mineral materials includes a vertical cylinder calciner 1, a combustion furnace 2, a dust collector 3, an induced draft fan 4, and a temperature measuring instrument 5. The top of the vertical cylinder calciner is provided with a feed port 6, and the vertical cylinder The bottom of the calciner 1 communicates with the combustion furnace 2 ; the vertical tube calciner 1 is provided with a preheating pipe 7 , and the preheating pipe 7 extends into the combustion furnace 2 .

[0062] Mineral raw materials are pulverized to obtain mineral powder. The mineral powder enters the vertical calciner 1 through the feed port 6. During the sinking process, the mineral powder is fully preheated by the preheating pipe 7...

Embodiment 2

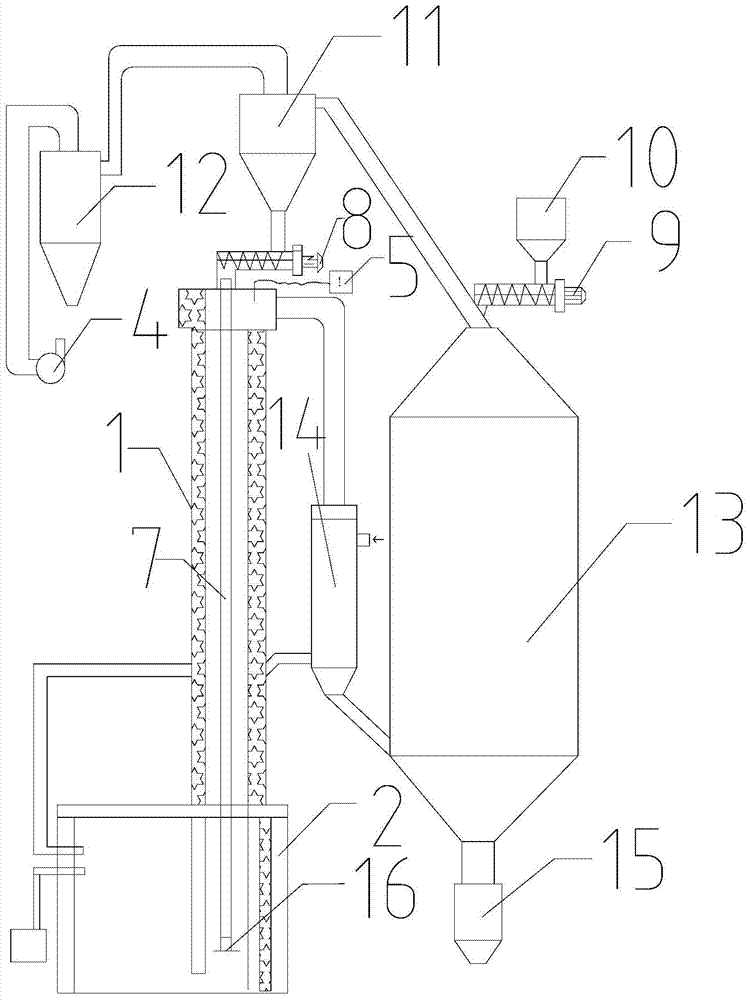

[0089] figure 2 It is a schematic diagram of another device for implementing the method for producing highly active mineral materials provided by the embodiment of the present invention. From figure 2 It can be seen that the device includes a vertical calciner 1, a combustion furnace 2, a dust collector, an induced draft fan 4, a silo 10, a meter 9, and a discharger 8;

[0090] Wherein, the silo 10 is connected with the meter 9, and the unloader 8 is connected with the feed port, and the meter 9 is used to control the amount of the mineral powder in the silo 10 entering the unloader 8. Mineral raw materials are crushed by a crusher and ground to a specified fineness by a pulverizer to obtain mineral powder. The mineral powder is transported to the silo by the elevator, and then transported to the unloader 8 by the meter 9 (such as a spiral metering reamer). (such as the air lock valve), and then the mineral powder enters the vertical calciner 1 through the feed port. Duri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com