Novel low-energy MBR (Membrane Bioractor) sewage treatment complete equipment and remote control system

A remote control system, low energy consumption technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the difficulties in maintenance and management of small sewage treatment equipment, nitrogen and phosphorus removal Complicated process and other issues, to achieve the effect of excellent effluent water quality, low frequency of membrane cleaning, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

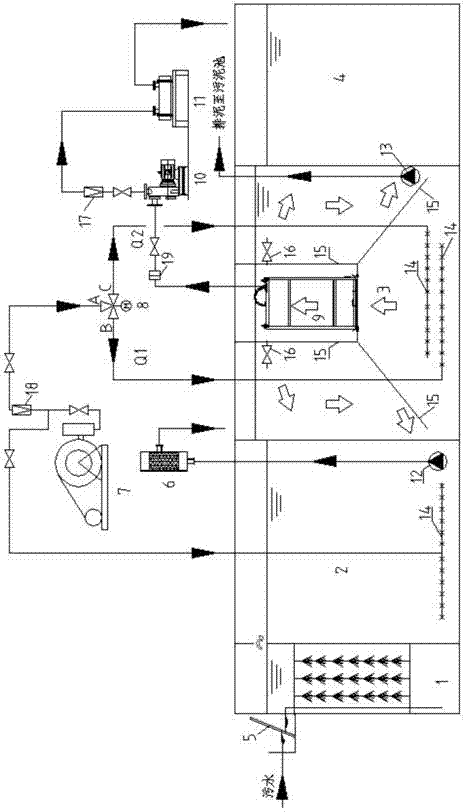

[0052] Attached below Figure 1-2 Explained to further understand the present invention.

[0053] (1) Assembly of MBR sewage treatment equipment: Stabilizing tank 1, regulating tank 2, integrated A2 / O-MBR tank 3, and medium tank 4 can be made of glass fiber reinforced plastic or anti-corrosion carbon steel or steel concrete. The size of the tank is based on the residence time and The processing capacity of the equipment is determined. Install elastic packing in the stabilization tank 1. The fine grid 5 is installed in the inlet channel before the stabilization tank 1 or in the stabilization tank 1. The outlet pipe of the lift pump 12 installed in the adjustment tank 2 is connected to the inlet of the automatic cleaning filter 6. , The effluent of the automatic cleaning filter 6 is evenly distributed into the integrated A2 / O-MBR pool 3.

[0054] The deflector 15 separates the integrated A2 / O-MBR pool 3 into a rising zone and a descending zone. There is a 20-50cm gap between the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com