Vacuum pump wastewater treatment system and use method thereof

A wastewater treatment system and vacuum pump technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of excessive discharge of wastewater, poor biodegradability of wastewater, and increase of wastewater treatment stations Deal with load and other issues to achieve the effect of saving water resources and meeting water quality standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

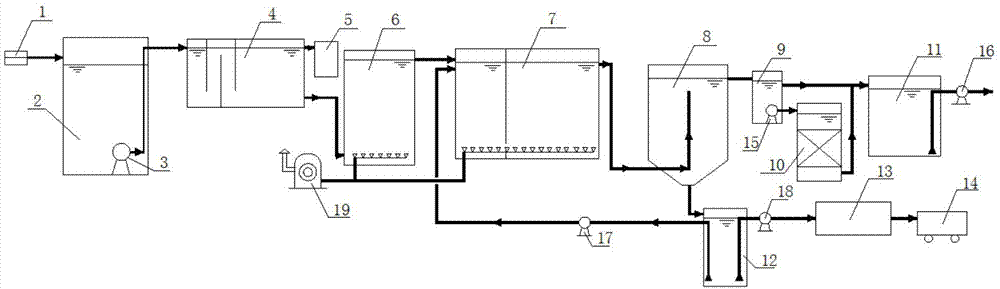

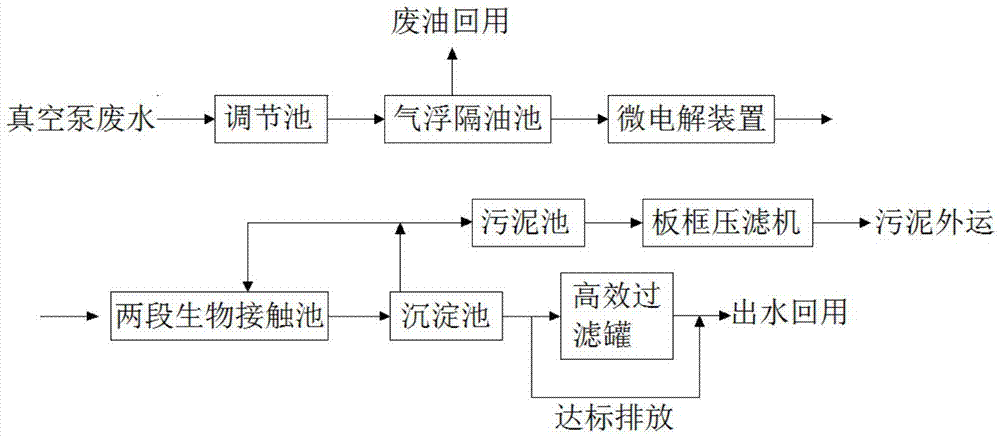

[0018] A vacuum pump wastewater treatment system, consisting of a regulating tank (2), a lift pump (3), an air flotation grease trap (4), a waste oil recovery tank (5), an aeration micro-electrolysis device (6), two stages of biological contact Oxidation tank (7), sedimentation tank (8), water collection tank (9), high-efficiency filter tank (10), reuse water storage tank (11), sludge tank (12), plate and frame filter press (13), sewage The mud transport vehicle (14), the lifting water pump (15), the reuse water pump (16), the sludge return pump (17), the sludge lifting pump (18), and the fan room (19); the waste water of the vacuum pump (1) passes through The pipeline in the factory area is connected to the water inlet pipe of the regulating tank (2), and the wastewater in the regulating tank (2) enters the water inlet of the air flotation grease trap (4) through the lift pump (3), and the air flotation grease trap (4) isolates Slick oil and scum enter the waste oil recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com