Microwave-assisted Fenton strengthened landfill leachate membrane filtration concentrated solution treatment method

A technology for landfill leachate and concentrated liquid, which is applied in dehydration/drying/concentrated sludge treatment, chemical instruments and methods, oxidized water/sewage treatment, etc. problems, to achieve the effect of improving the pretreatment effect, saving the processing cost and reducing the operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings.

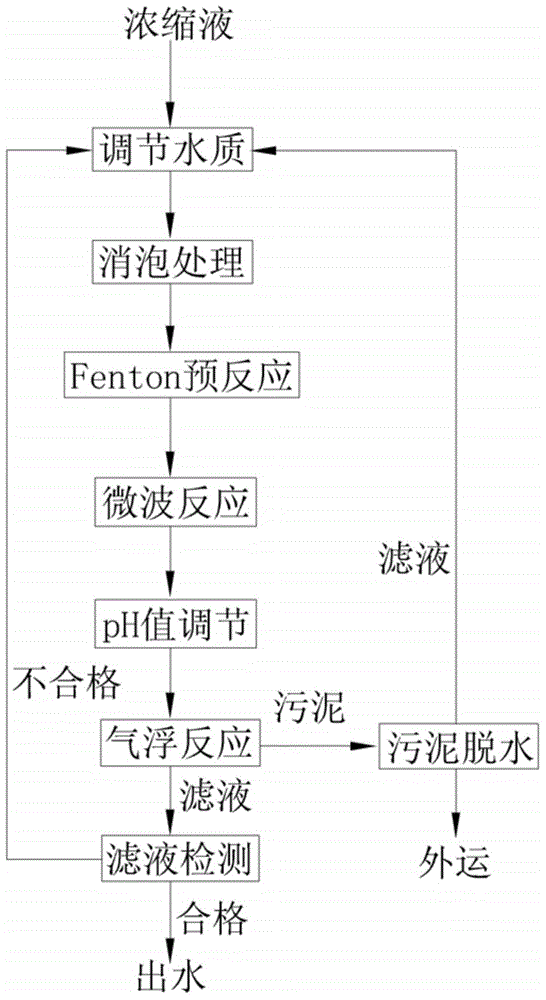

[0016] The method for microwave and Fenton-enhanced membrane filtration concentrate treatment of landfill leachate of the present invention is mainly composed of six processes: water quality adjustment, Fenton pre-reaction, microwave reaction, air flotation reaction, mud-water separation and pH value adjustment. The specific process flow of the method like figure 1 As shown, it includes the following steps:

[0017] 1) Adjust water quality: Due to the great difference in the water quality of the concentrate, before performing the Fenton pre-reaction, it is necessary to adjust the water quality and water quantity of the concentrate to be treated to a certain extent, that is, according to the water quantity and pH value of the concentrate, put the A certain amount of sulfuric acid is added to the adjustment tank of the concentrated solution to adjust the pH value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com