Preparation method of phthalocyanin modified cerium dioxide nano particles

A technology of cerium dioxide and nanoparticles, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as easy agglomeration, difficult recovery, strong adsorption, etc., and meet the reaction conditions Mild, easy to operate, uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

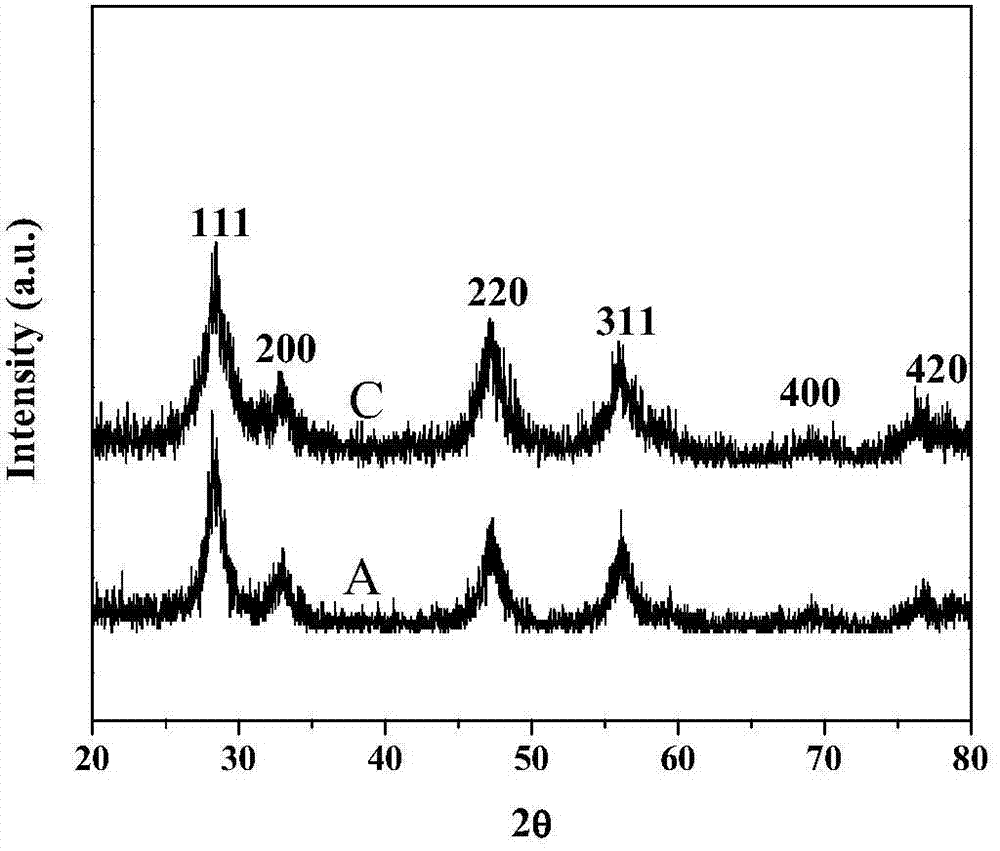

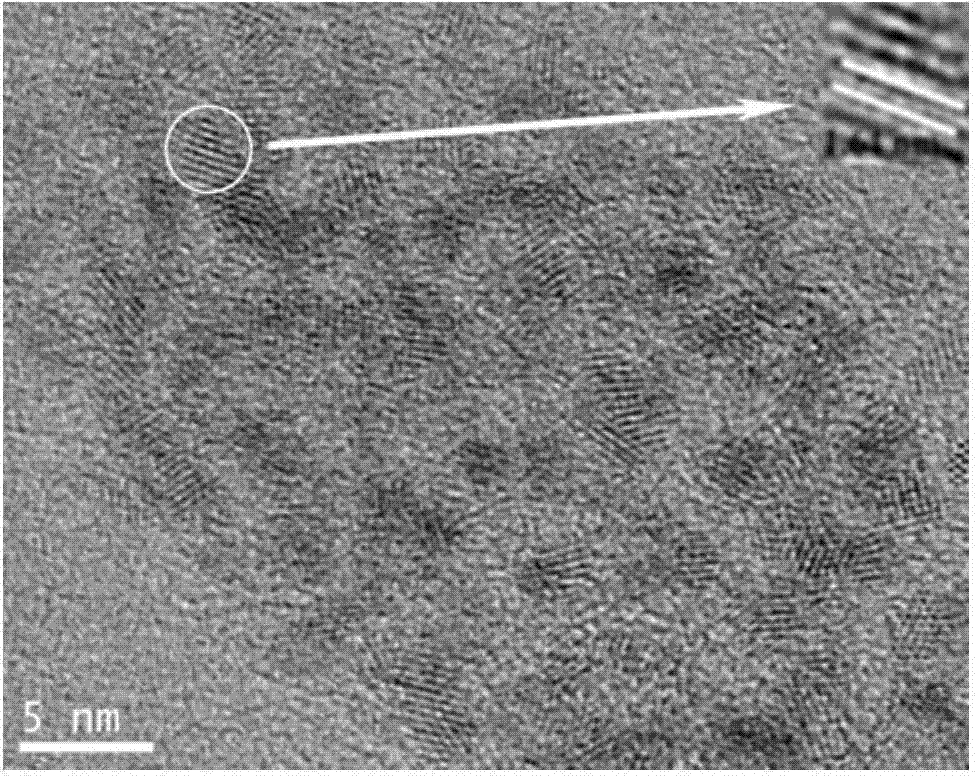

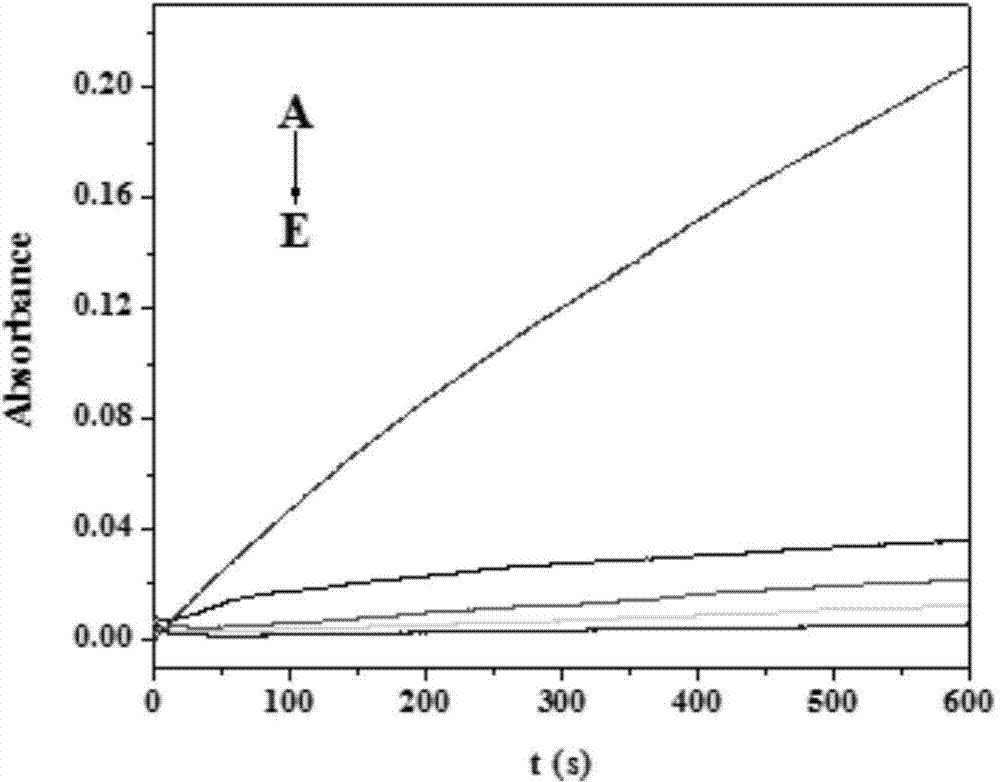

Embodiment 1

[0023] Weigh 0.1085g (about 0.25mM) Ce(NO 3 ) 3 ·6H 2 O was dissolved in 10 mL of deionized water to obtain a clear solution A for use. Weigh 5 mg of phthalocyanine and dissolve it in 10 mL of deionized water, and adjust the pH of the solution to ≈8 with NaOH to obtain solution B. The clear solution A and solution B were mixed and stirred for 30 min to obtain a mixed solution. Inject 200 μl HO with a microsampler 2 o 2 Afterwards, continue to stir for 30 minutes, then transfer to a reaction kettle, and heat at 150° C. for 6 hours. After cooling to room temperature, the product obtained was washed with NaOH (pH≈8) deionized water and absolute ethanol for 4 times by high-speed centrifugation. After washing, the product was transferred to a watch glass and dried at 60°C for 10 hours to obtain a dark yellow powder. Phthalocyanine-modified ceria nanoparticles. The product purity of the phthalocyanine-modified cerium dioxide nanoparticles is 100%, and the yield is 97.9%.

[...

Embodiment 2

[0026] Weigh 0.1085g (about 0.25mM) Ce(NO 3 ) 3 ·6H 2 O was dissolved in 10 mL of deionized water to obtain a clear solution A for use. Weigh 6 mg of phthalocyanine and dissolve it in 10 mL of deionized water, and adjust the pH of the solution to ≈8 with NaOH to obtain solution B. The clear solution A and solution B were mixed and stirred for 45 min to obtain a mixed solution. Inject 250 μl H with a microsampler 2 o 2 Afterwards, continue to stir for 30 minutes, then transfer to a reaction kettle, and heat at 140° C. for 7 hours. After cooling to room temperature, the product obtained was washed with NaOH (pH≈8) deionized water and absolute ethanol for 4 times by high-speed centrifugation. After washing, the product was transferred to a watch glass and dried at 70°C for 10 hours to obtain a dark yellow powder. Phthalocyanine-modified ceria nanoparticles. The product purity of the phthalocyanine-modified cerium dioxide nanoparticles is 100%, and the yield is 94.5%.

Embodiment 3

[0028] Weigh 0.1085g (about 0.25mM) Ce(NO 3 ) 3 ·6H 2 O was dissolved in 10 mL of deionized water to obtain a clear solution A for use. Weigh 4 mg of phthalocyanine and dissolve it in 10 mL of deionized water, and adjust the pH of the solution to ≈8 with NaOH to obtain solution B. The clear solution A and solution B were mixed and stirred for 30 min to obtain a mixed solution. Inject 180 μl HO with a microsampler 2 o 2 Afterwards, continue to stir for 30 minutes, then transfer to a reaction kettle, and heat at 160° C. for 5 hours. After cooling to room temperature, the product obtained was washed with NaOH (pH≈8) deionized water and absolute ethanol for 4 times by high-speed centrifugation. After washing, the product was transferred to a watch glass and dried at 65°C for 12 hours to obtain a dark yellow powder. Phthalocyanine-modified ceria nanoparticles. The product purity of the phthalocyanine-modified cerium dioxide nanoparticles is 100%, and the yield is 94.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com