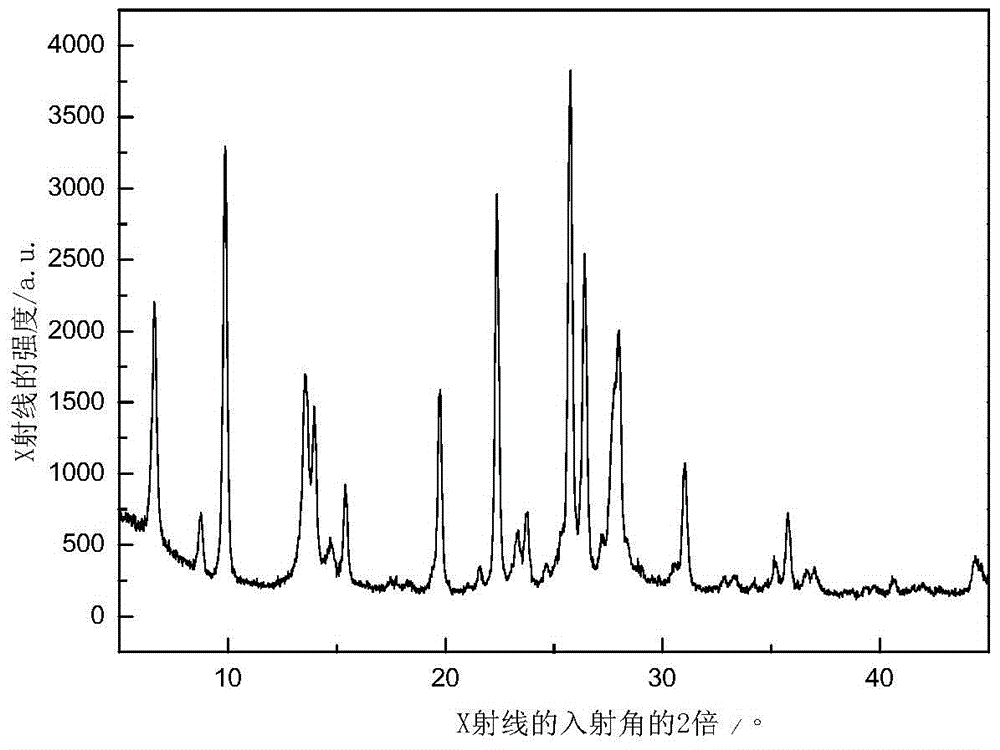

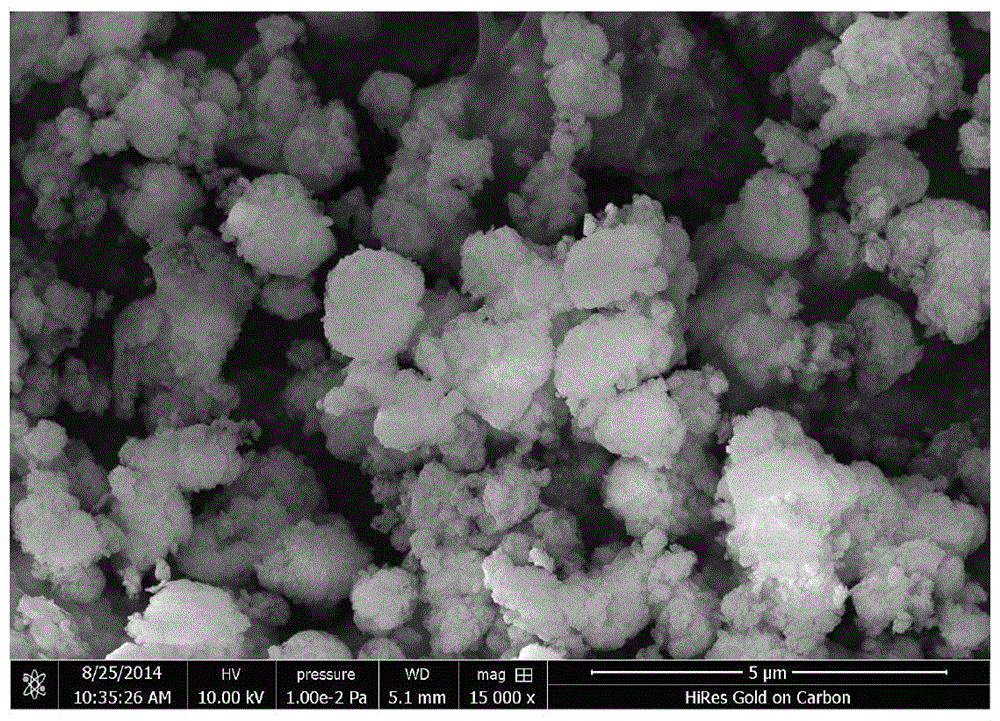

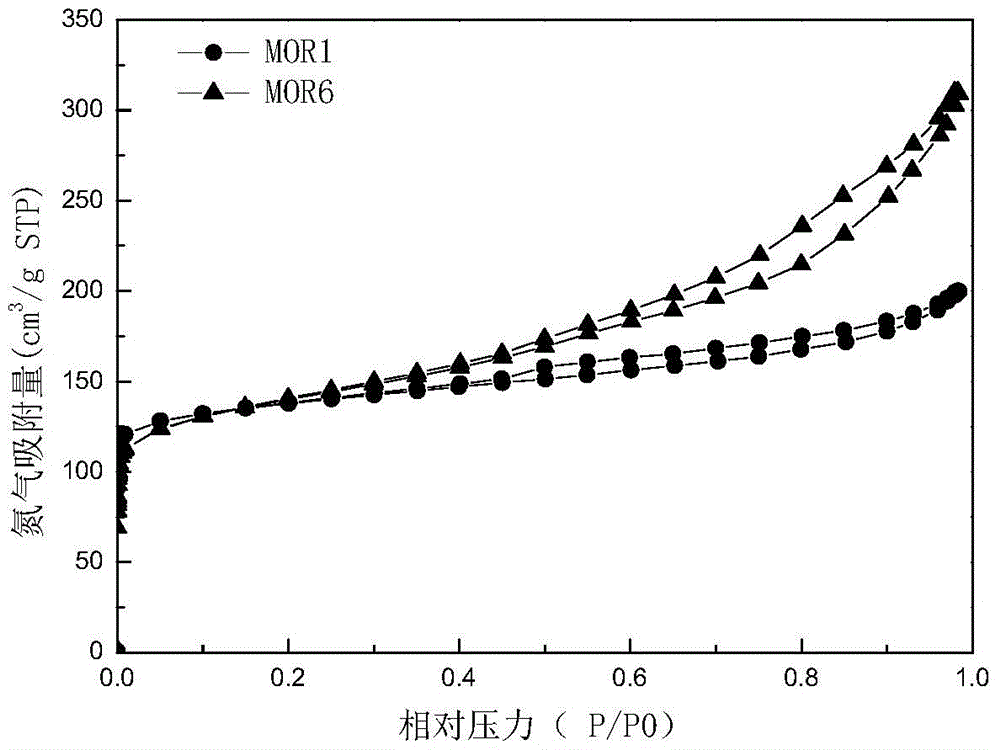

A kind of preparation method of nanometer step hole mordenite molecular sieve

A technology of denzeolite and molecular sieve, which is applied in the field of preparation of nano-scale pore mordenite molecular sieve, can solve the problems of reducing the concentration of crystallization liquid, prolonging the crystallization time, complicated operation, etc., and achieves the improvement of hydrodealkylation performance and the reduction of crystal The effect of particle size and conversion rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 4.0g sodium hydroxide (0.1mol NaOH) was dissolved in 30ml water, and white carbon black (0.5mol SiO 2 ), stirring at room temperature for 1h (magnetic stirring, stirring at a speed of about 20r / min), forming an alkaline white carbon black solution; 8.2g of sodium metaaluminate (equivalent to 0.05mol Al 2 o 3 ) was dissolved in 42ml of water and added to the alkaline white carbon black solution, stirred at room temperature for 1 hour to form a uniform silicon-aluminum mixed solution, added 1.5g of mesoporous soft template agent polyethylene glycol 10000, stirred for 1 hour, and then added 0.3g of mercerized Zeolite seed crystals were stirred for 1 h to obtain a gel mixture. The SiO of this gel mixture 2 / Al 2 o 3 Molar ratio = 10, H 2 O / SiO 2 Molar ratio = 8, NaOH / SiO 2 Molar ratio = 0.2, seed M / SiO 2 Mass ratio = 0.01, mesoporous soft templating agent R / SiO 2 Mass ratio = 0.05. The mixed solution was dynamically crystallized at 150°C and 20r / min for 24h. The ...

Embodiment 2

[0030] 2.4g of sodium hydroxide (0.06mol NaOH) was dissolved in 20ml of water, and 40g of silica sol (SiO 2 The content is 30wt%, equivalent to 0.2mol SiO 2 ) solution, stirred at room temperature for 1h to form an alkaline silica sol solution; 2.7g aluminum chloride (equivalent to 0.01mol Al 2 o 3 ) was dissolved in 38ml of water and added to the alkaline silica sol solution, stirred at room temperature for 1h to form a uniform silicon-aluminum mixed solution, added 1.2g of mesoporous soft template agent polyethylene glycol 4000, stirred for 1h, and then added 0.2g of mordenite The seed crystals were stirred for 1 h to obtain a gel mixture. The SiO of this gel mixture 2 / Al 2 o 3 Molar ratio = 20, H 2 O / SiO 2 Molar ratio = 16.2, NaOH / SiO 2 Molar ratio = 0.3, seed M / SiO 2 Mass ratio = 0.02, mesoporous soft templating agent R / SiO 2 Mass ratio = 0.1. The mixed solution was dynamically crystallized at 130°C and 20r / min for 72h. After cooling, filtering and washing, th...

Embodiment 3

[0033] 2.8g sodium hydroxide (0.07mol NaOH) is dissolved in 50ml water, in the sodium hydroxide solution that forms, add the water glass (0.18molSiO2) that contains silicon dioxide 11g 2 ), stirred at room temperature for 1h to form an alkaline water glass solution; 0.82g sodium metaaluminate (equivalent to 0.05mol Al 2 o 3 ) was dissolved in 38ml of water and added to the alkaline water glass solution, stirred at room temperature for 1h to form a uniform silicon-aluminum mixed solution, added 1.6g of mesoporous soft template agent CTAB, stirred for 1h, then added 0.3g of mordenite seed crystals and stirred for 1h to obtain a gel mixture. The SiO of this gel mixture 2 / Al 2 o 3 Molar ratio = 35, H 2 O / SiO 2 Molar ratio = 27.2, NaOH / SiO 2 Molar ratio = 0.4, seed M / SiO 2 Mass ratio = 0.03, soft templating agent R / SiO 2 Mass ratio = 0.15. The mixed solution was dynamically crystallized at 110°C and 20r / min for 84h. The crystallized product was cooled, filtered and wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com