Method for preparing nitrogen doped porous carbon material by using biologic proteins

A technology of biological protein and porous carbon, which is applied in the field of porous carbon materials, can solve the problems of lack of pore size distribution control means, low content of nitrogen elements, and weak specific application, and achieves easy industrialization, simple design process, The effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

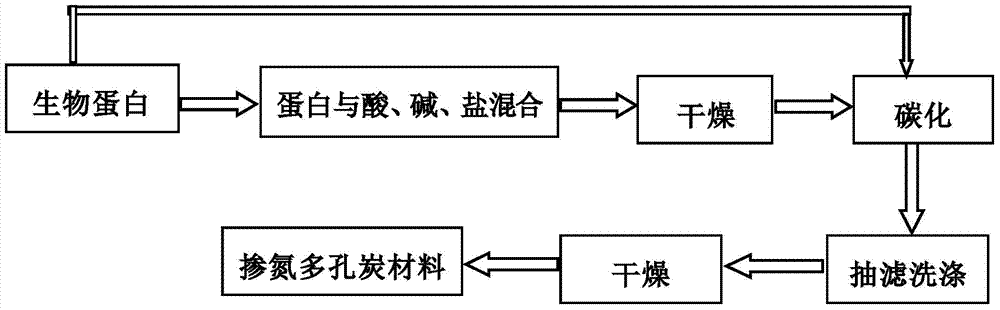

Image

Examples

Embodiment 1

[0027] A nitrogen-doped porous carbon material prepared by using the preparation system of the present invention.

[0028] Step 1: Mix silk fibroin with one of the acidic substances or solutions under natural conditions or at low temperature;

[0029] Step 2: carbonize the dried mixture at 850° C. under the protection of an inert gas.

[0030] Step 3: add distilled water to filter and wash until the pH value is 6.4-7, and then dry to prepare a nitrogen-doped porous carbon material.

Embodiment 2

[0032] A nitrogen-doped porous carbon material prepared by using the preparation system of the present invention.

[0033] Step 1: Mix soybean protein with acidic substance or solution under natural conditions or at low temperature;

[0034] Step 2: The dried mixture is irradiated with microwaves at a power of 1000W for 40 minutes in a microwave device under the protection of an inert gas.

[0035] Step 3: add distilled water to filter and wash until the pH value is 6.4-7, and then dry to prepare a nitrogen-doped porous carbon material.

Embodiment 3

[0037] A nitrogen-doped porous carbon material prepared by using the preparation system of the present invention.

[0038] Step 1: Mix silk fibroin with one of the acidic substances or solutions under natural conditions or at low temperature;

[0039] Step 2: carbonize the dried mixture in a tube furnace for 100 minutes under the protection of an inert gas.

[0040] Step 3: add distilled water to filter and wash until the pH value is 6.4-7, and then dry to prepare a nitrogen-doped porous carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com