Functional microcapsule-finished composite fabric

A technology of microcapsule finishing and composite fabrics, applied in the field of composite fabrics, can solve the problems of unguaranteed functionality, unsatisfactory hand feel, and small amount of microcapsules added, and achieve the effects of prolonging service life, avoiding mechanical friction, and prolonging the validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

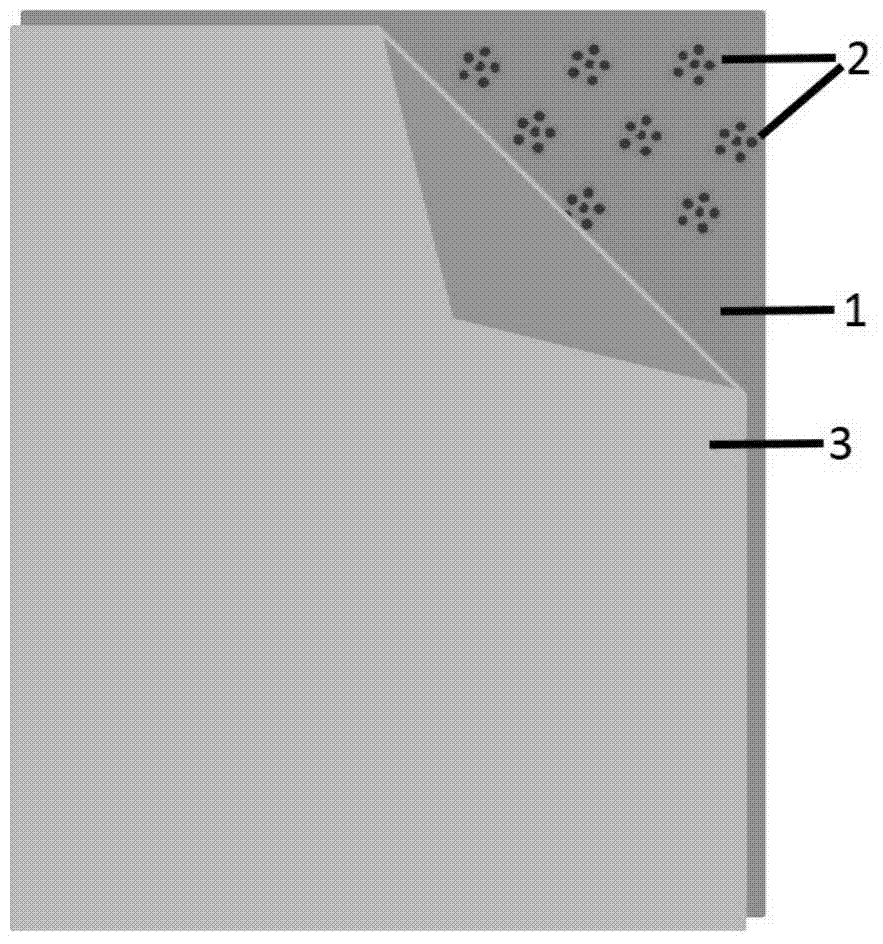

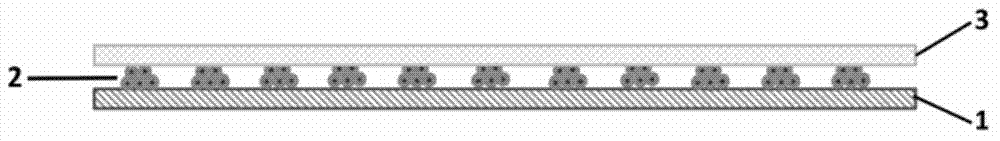

[0021] like figure 1 and figure 2 As shown, an aromatic microcapsule finishing composite fabric is composed of a fabric layer 1, a microcapsule layer 2 and a third layer 3; Evenly distributed between the fabric layer and the third layer; the fabric layer chooses knitted pure cotton cloth, and uses printing technology to evenly disperse the microcapsules on the fabric layer in the form of spots; the third layer also chooses knitted pure cotton cloth, through bonding The agent is connected with the fabric layer and the microcapsule layer. The aromatic microcapsule finishing composite fabric can be prepared.

[0022] The specific printing process is:

[0023] 1. Prepare microcapsule emulsion: mix and prepare according to the following weight percentages:

[0024] Lavender-type aroma microcapsules: 2-15%

[0025] Binder: 5-20%

[0026] Thickener: 2-10%

[0027] The rest is water.

[0028] 2. Cover the prepared microcapsule emulsion on the fabric layer by a printing proces...

Embodiment 2

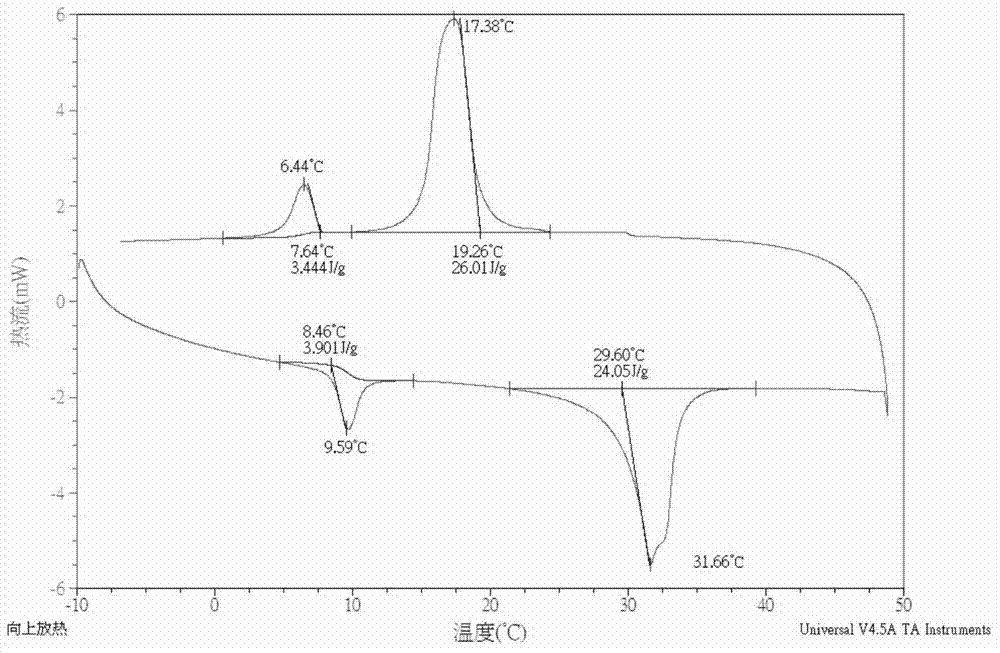

[0031] like figure 1 and figure 2 As shown, a temperature-regulating microcapsule finishing composite fabric is composed of fabric layer 1, microcapsule layer 2 and third layer 3; microcapsule layer 2 is composed of phase change microcapsules, and the phase change microcapsules are spotted and even Scattered and distributed between the fabric layer and the third layer; the fabric layer chooses woven pure cotton cloth, and uses coating technology to evenly disperse microcapsules on the fabric layer in the form of spots; the third layer chooses woven polyester fabric, through bonding The agent is connected with the fabric layer and the microcapsule layer. The temperature-regulating microcapsule composite fabric can be prepared. like image 3 As shown, the exothermic enthalpy value of the composite fabric is 26.01J / g.

[0032] The specific coating process is:

[0033] 1. Prepare microcapsule emulsion: mix and prepare according to the following weight percentages:

[0034] ...

Embodiment 3

[0041] like figure 1 and figure 2 As shown, a flame-retardant microcapsule finishing composite fabric is composed of fabric layer 1, microcapsule layer 2 and third layer 3; microcapsule layer 2 is composed of flame-retardant microcapsules, and the flame-retardant microcapsules are spot-like, Scattered and distributed between the fabric layer and the third layer; the fabric layer chooses woven polyester-cotton cloth, adopts the transfer coating process to evenly disperse the microcapsules on the fabric layer in the form of spots; the third layer chooses PU polymer film, through lamination Composite, connected with fabric layer and microcapsule layer. The flame-retardant microcapsule composite fabric can be prepared.

[0042] The specific transfer coating process is:

[0043] 1. Prepare microcapsule emulsion: mix and prepare according to the following weight percentages:

[0044] Flame retardant microcapsules: 10-75%

[0045] Binder: 5-15%

[0046] Thickener: 2-5%

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com