Feeding device

A feeding device and coil material technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of stamping failure, heavy weight, and inconvenient handling, so as to reduce labor force, improve production and processing performance, facilitate handling and The effect of repositioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

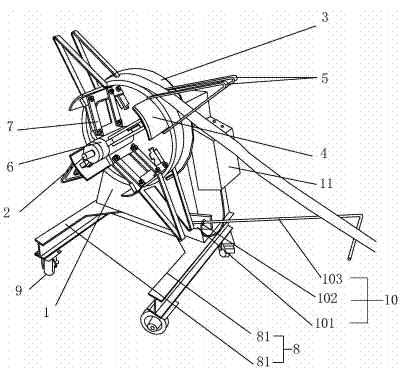

[0011] A feeding device, comprising a machine base 1, on which a rotating shaft 2 and a coiler for coiling a strip material are arranged, the rotating shaft 2 and the coiler are arranged coaxially, and the coiler includes a fixed stop Plate 3 and some movable baffles 4 that can be wound around the strip coil, the movable baffle 4 is provided with a retaining strip 5 that can limit the strip coil, and the retaining strip 5 is symmetrically distributed on both sides of the strip coil, The base 1 is provided with an underframe 8, and under the underframe 8 is provided with a roller 9. The base 1 is provided with a feeding induction device 10 and a stepping motor 11 linked with the rotating shaft 2. The feeding induction device 10 and the stepping motor 11 Electrical connections.

[0012] By adopting the above-mentioned technical scheme, the machine base 1 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com