Flotation technology of middle-low-grade silica-calcia bearing phosphate rock

A collophosite, low-grade technology, applied in the flotation process of low-grade silica-calcium collophosite, can solve the problems of excessive foam, poor sorting, large amount of slime, etc., and achieve a reasonable process flow , Excellent foaming phenomenon and less dosage of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

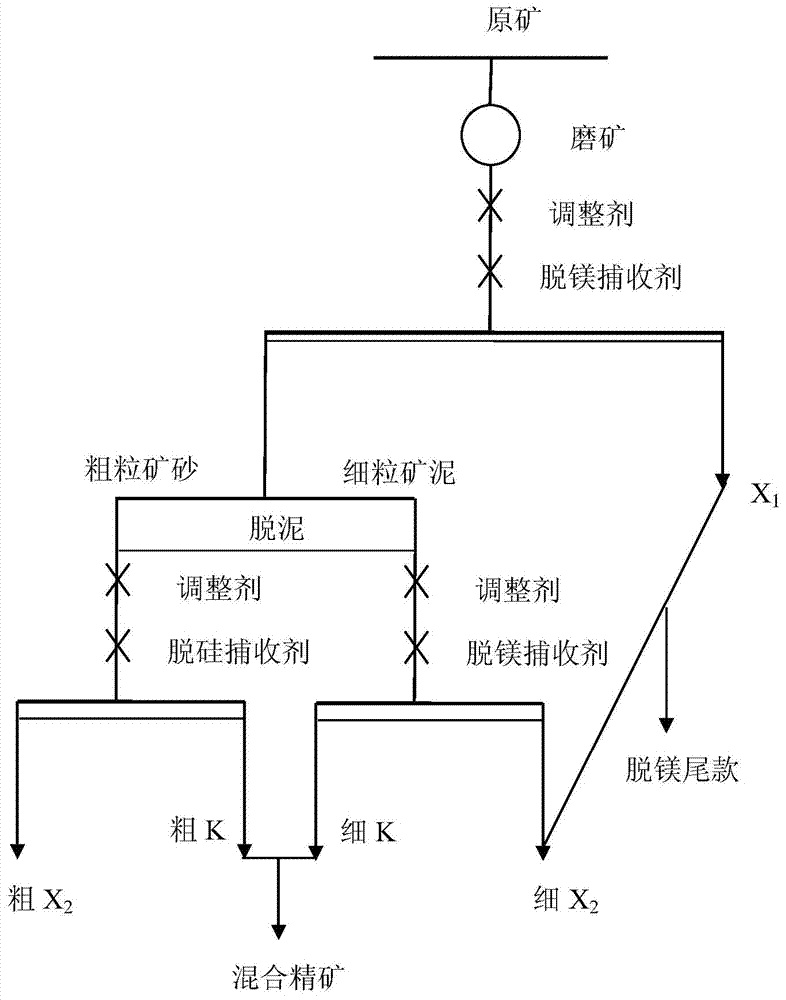

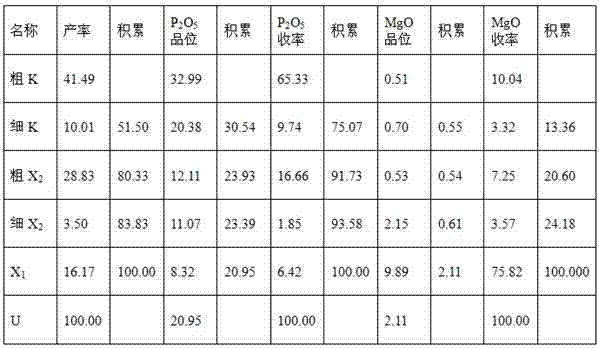

[0023] Embodiment 1, with reference to figure 1 , a low-grade siliceous-calcium colloidal flotation process, specifically comprising the following steps:

[0024] (1) Crushing the raw ore of middle and low-grade collophosphine and then grinding until the mineral monomers are dissociated;

[0025] (2) Add water to the grinding product to adjust the slurry to a suitable concentration and then enter the stirring tank, add an appropriate amount of regulator phosphoric acid and reverse flotation magnesium removal collector to adjust the slurry, and the material after slurry adjustment enters the reverse flotation system for reverse flotation demagnesia For magnesium operation, the foam product is demagnesium tailings, and the product in the tank is demagnesium concentrate;

[0026] (3) Perform desliming operation on the demagnesized concentrate to obtain coarse-grained ore products and fine-grained slime products;

[0027] (4) The coarse ore product is mixed with water to a suita...

Embodiment 2

[0030] Embodiment 2, in the flotation process of a kind of middle and low grade siliceous calcareous collophosphine described in embodiment 1: the main composition of described middle and low grade collophosite is: P 2 o 5 The grade of MgO is 10~30%, the grade of MgO is 2~10%, and the grade of SiO 2 The grade is 10~40%, and the rest are impurities.

Embodiment 3

[0031] Example 3, in a medium-low-grade siliceous-calcium colloidal phosphate rock flotation process described in Example 1 or 2: the grinding fineness in step (1) is -0.074 mm, and the particle size accounts for 45-85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com