A special RO phase magnetic separator for steel slag powder

A steel slag fine powder and magnetic separator technology, applied in the field of magnetic separators, can solve problems such as inability to separate, unable to achieve effective separation, and non-collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

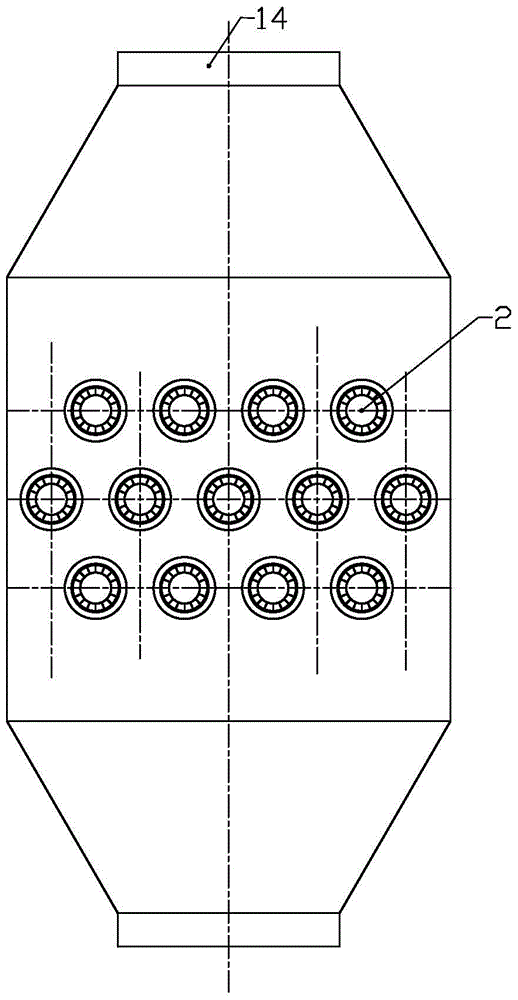

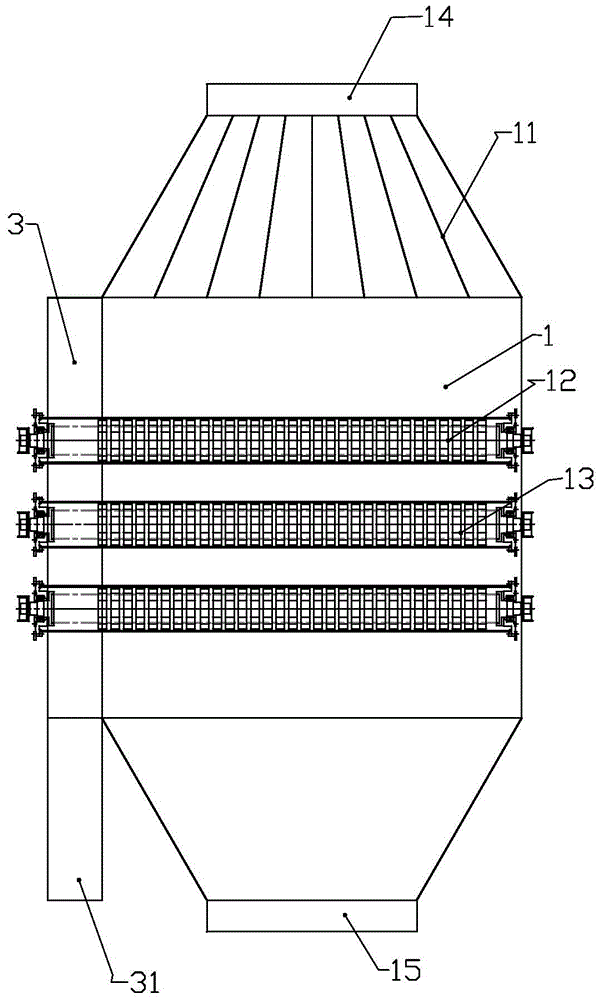

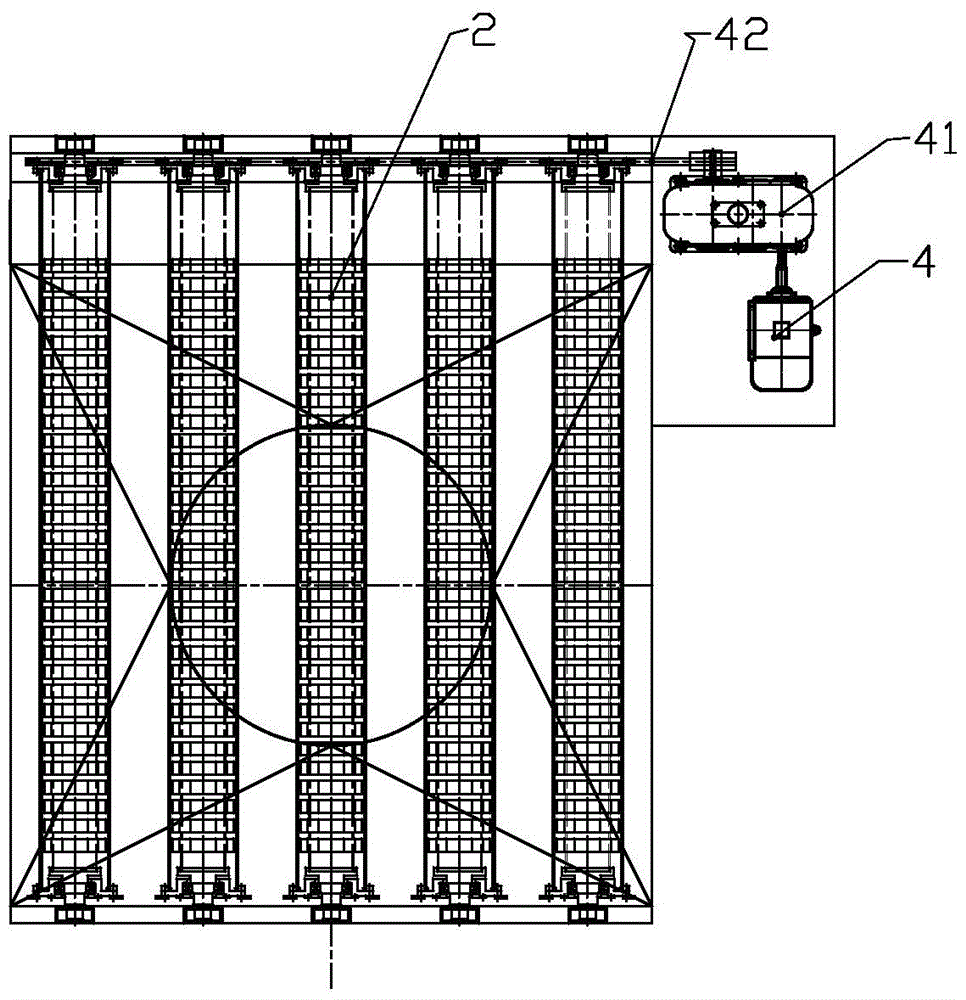

[0029] Such as Figure 1 to Figure 6 As shown, for existing defects, the subject of protection of the present invention is as follows:

[0030] A special RO phase magnetic separation equipment for preparing steel slag powder by vertical mill is developed. This equipment replaces a section of air material pipeline between vertical mill and dust collector, does not change the process layout of the existing production system, and has great impact on the air volume and air pressure of the system. No engineering impact. The equipment is designed with a square sorting chamber 1, the wind from the mill and steel slag fine powder enter the sorting chamber evenly through the deflector 11 at the upper end of the sorting chamber 1, and the wind carries the steel slag fine powder into the magnetic rod assembly 2 Composed of the upper magnetic separation layer 12, the RO phase is adsorbed on the surface of the magnetic rod assembly 2, and other materials enter the next-level magnetic rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com