Preparation method of high-quality low-salt pickles

A high-quality, kimchi technology, used in food preparation, ultra-high pressure food processing, and the function of food ingredients to reduce bacteria, ensure shelf life, and maintain flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

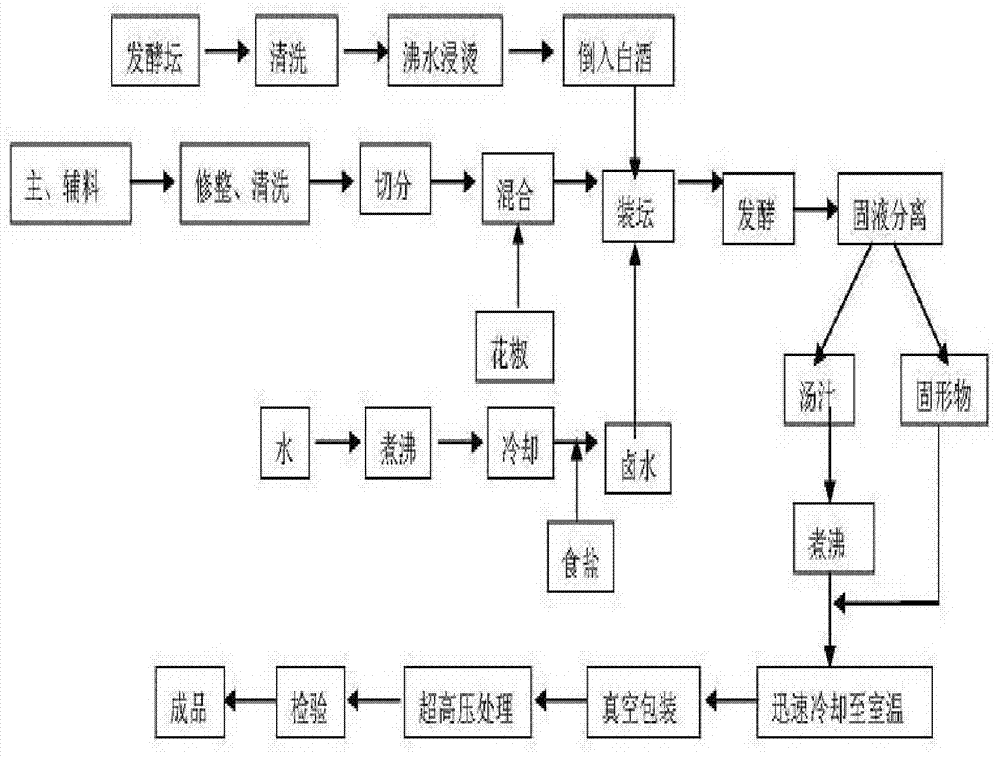

Method used

Image

Examples

Embodiment 1

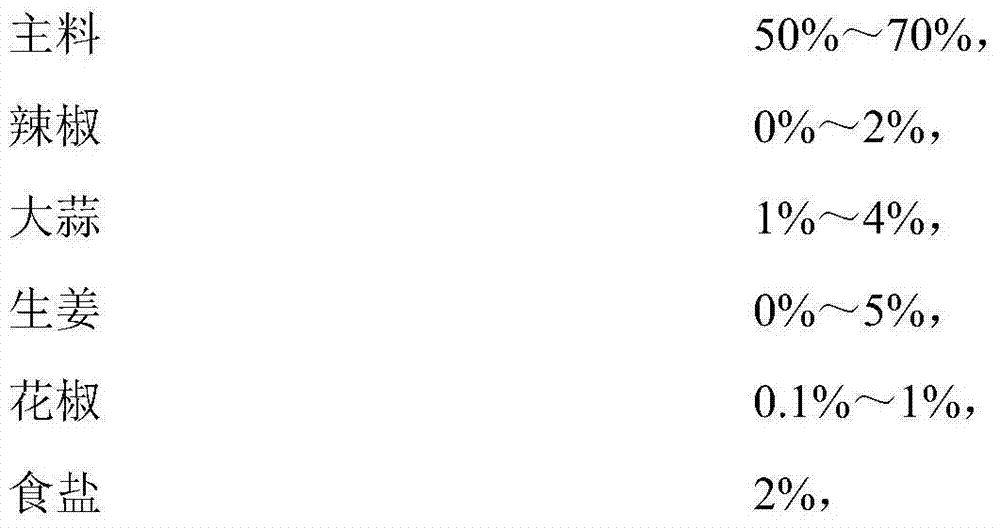

[0033] (1) Material preparation: choose fresh white radish with consistent maturity as the main material, and red pepper, garlic and ginger as auxiliary materials;

[0034] (2) Cleaning: raw materials are cleaned of sediment and dirt, and cleaned at least three times;

[0035] (3) Slicing: Cut the washed main ingredients into strips (8cm×1cm×1cm), slice garlic, shred ginger, and cut pepper into 1cm sections;

[0036] (4) Filling the altar: Pour 2 / 3 of the white wine in the formula into the empty altar, and mix the radish, garlic, ginger, pepper and peppercorns cut in (3) evenly, put it into the altar, and put it in the altar Mouth 12cm, gently press firmly;

[0037] (5) brine preparation: take table salt and cold boiled water according to the formula ratio, dissolve, and make brine;

[0038] (6) Brewing: Pour the prepared brine into the jar filled with main and auxiliary materials. It is advisable to submerge the vegetables and keep a distance of 10cm from the mouth of the j...

Embodiment 2

[0048] In embodiment one, the main ingredients are changed to cabbage, carrot, and celery by 8:1:1, and the main ingredients are changed to flakes in step (3), and the solid-to-liquid ratio is changed to 1 in step (8): 7. The time is changed to 20s, and the ultra-high pressure treatment condition in step (10) is changed to normal temperature and 400MPa pressure treatment for 10 minutes.

[0049] Other operating steps are the same as in Embodiment 1.

[0050] The kimchi obtained by the above method has good flavor, small nutritional loss, attractive color and good taste, the microbiological index meets the requirements of GB2714-2003 "Hygienic Standard for Sauces and Pickled Vegetables", and the shelf life at 4°C reaches 3 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com