Low and medium frequency sound insulation meta-material structure prepared by 3D printing

A 3D printing and metamaterial technology, applied in the direction of sensors, electrical components, sensor types, etc., can solve the problems of unsatisfactory fixing methods, affecting the service life of materials, complex processing technology, etc., to achieve light weight, simple structure and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

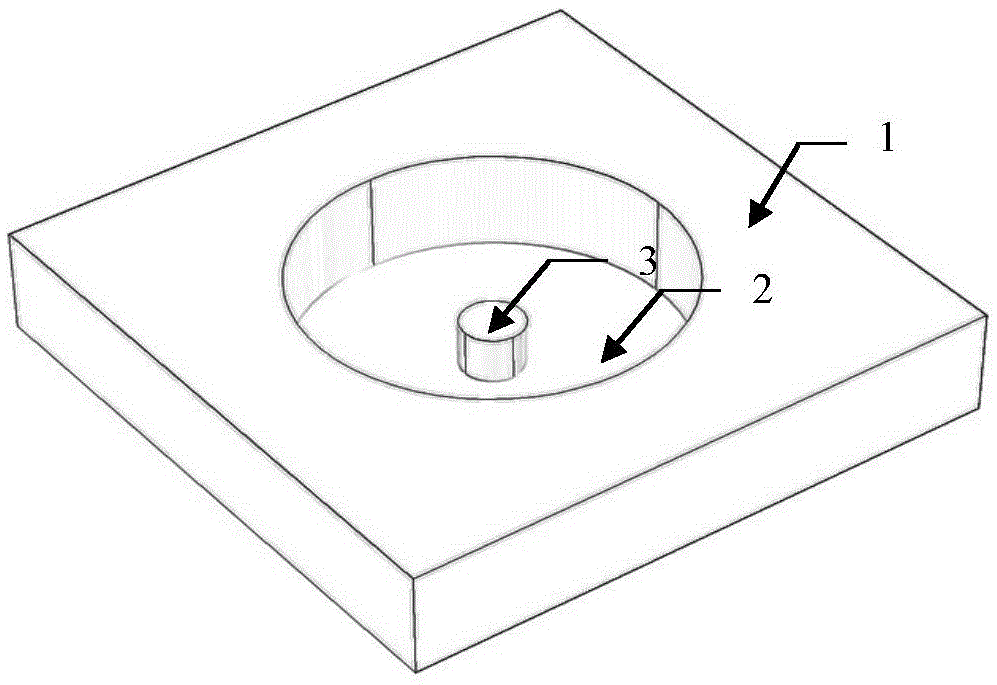

[0026] see figure 1 , figure 1 It is a structural schematic diagram of the first embodiment of the unit body of the medium and low frequency sound insulation metamaterial structure prepared by 3D printing technology in the present invention. As shown in the figure, a medium and low frequency sound insulation supermaterial prepared by 3D printing technology includes frame 1 1. The connecting body 2 and the central body 3 are integrally formed as a unit body, and the unit body is composed of a single material. The shape of these three parts can be any shape such as square, circle, triangle, etc. The thickness of the frame 1 and the central body 3 is 2mm-50mm thicker, and the thickness of the connecting body 2 is 0.2mm-10mm thinner, and the thickness ratio of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com