Composite reconstituted tobacco sheet, forming device and forming method thereof

A technology for reconstituting tobacco and forming equipment, applied in the directions of tobacco, tobacco preparation, application, etc., can solve problems such as being unsuitable for large-scale production, poor uniformity of sheet thickness, and ineffective arrangement of fibers, and achieves reduction of equipment investment and processing costs. Uniform thickness, ensuring physical strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

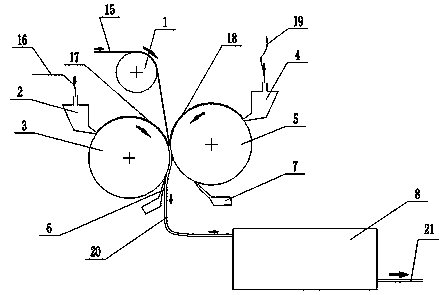

[0028] Such as figure 1 As shown, the composite reconstituted tobacco sheet forming equipment of this embodiment includes a conveyor roller 1, a left coating roller 3 and a right coating roller 5 arranged below the conveyor, and a left coating roller 3 and a right coating roller 5 The conventional drying device 8 below, the left coating roller 3 is provided with a first soot limiter feeding device 2, and the right coating roller 5 is provided with a second soot limiter feeding device 4, below the left coating roller 3 A left peeling device 6 is provided, and a right peeling device 7 is provided under the right coating roller 5. The distance between the left coating roller 3 and the right coating roller 5 can be adjusted.

[0029] The fiber web 15 is driven by the conveying roller 1 to pass between the left coating roller 3 and the right coating roller 5, and is pressed by the left coating roller 3 and the right coating roller 5 to form a strip of composite reconstituted tobacco ...

Embodiment 2

[0047] In this embodiment, the smoke slurry feeding device is a spraying device. By adjusting the position, the left limited spraying device 2 can spray the first smoke slurry on the left side of the fiber web 15 and bond them together as needed. The flow of the first smoke slurry can be any value required by the process, and the right limited spraying device 4 can The second smoke slurry is sprayed on the right side of the fiber web 15 and bonded together as needed, and the flow rate of the second smoke slurry can be any value required by the process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com