Rotor Concentrated Magnetic Double Stator Transverse Magnetic Field Permanent Magnet Synchronous Motor

A technology of permanent magnet synchronous motor and transverse magnetic field, applied to synchronous motors with stationary armature and rotating magnets, magnetic circuit shape/style/structure, electrical components, etc., which can solve the problem of low space utilization and winding utilization, Low torque density and power density, complex structure and other problems, to achieve the effect of shortening the ineffective length, improving torque density and power density, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

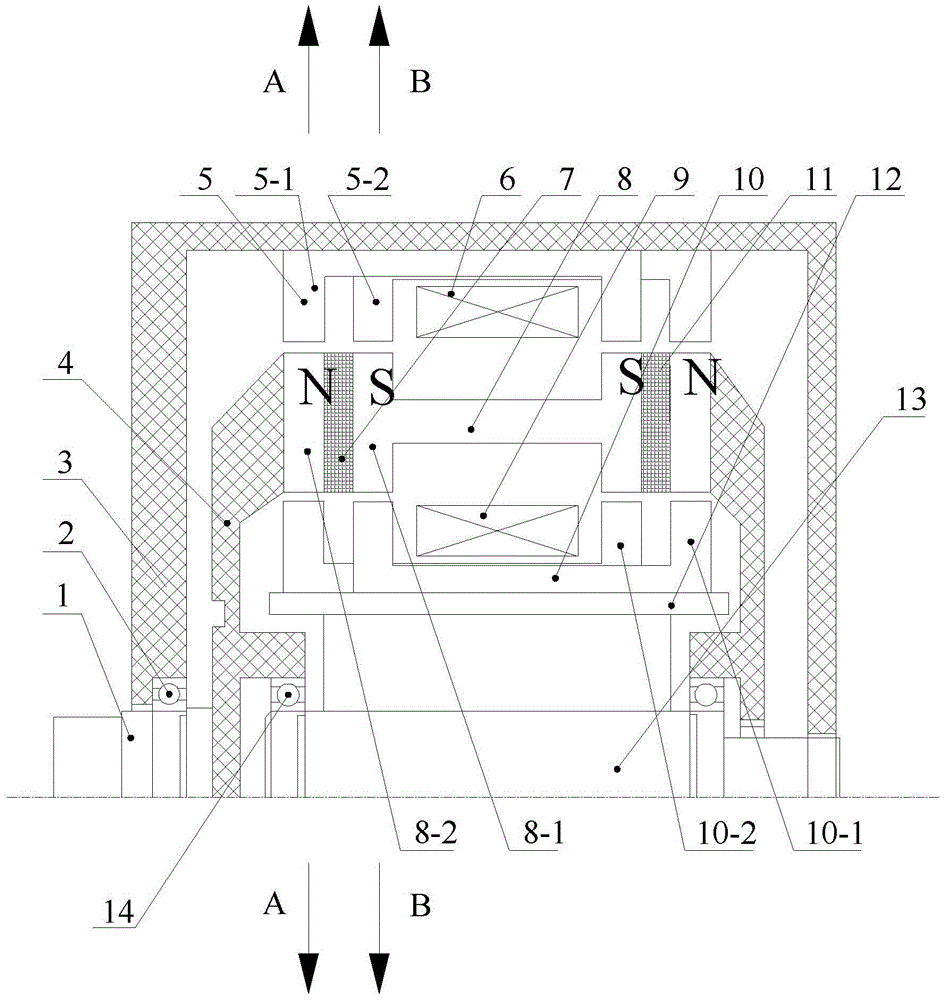

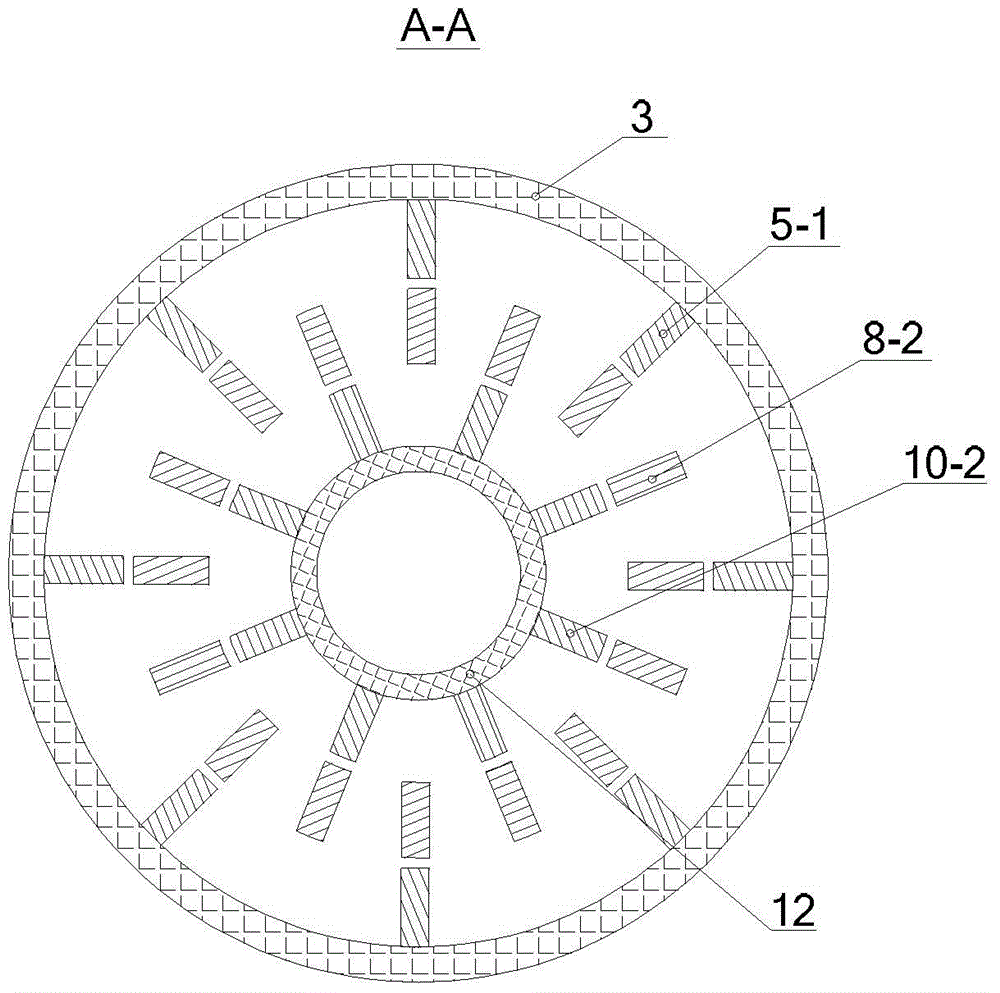

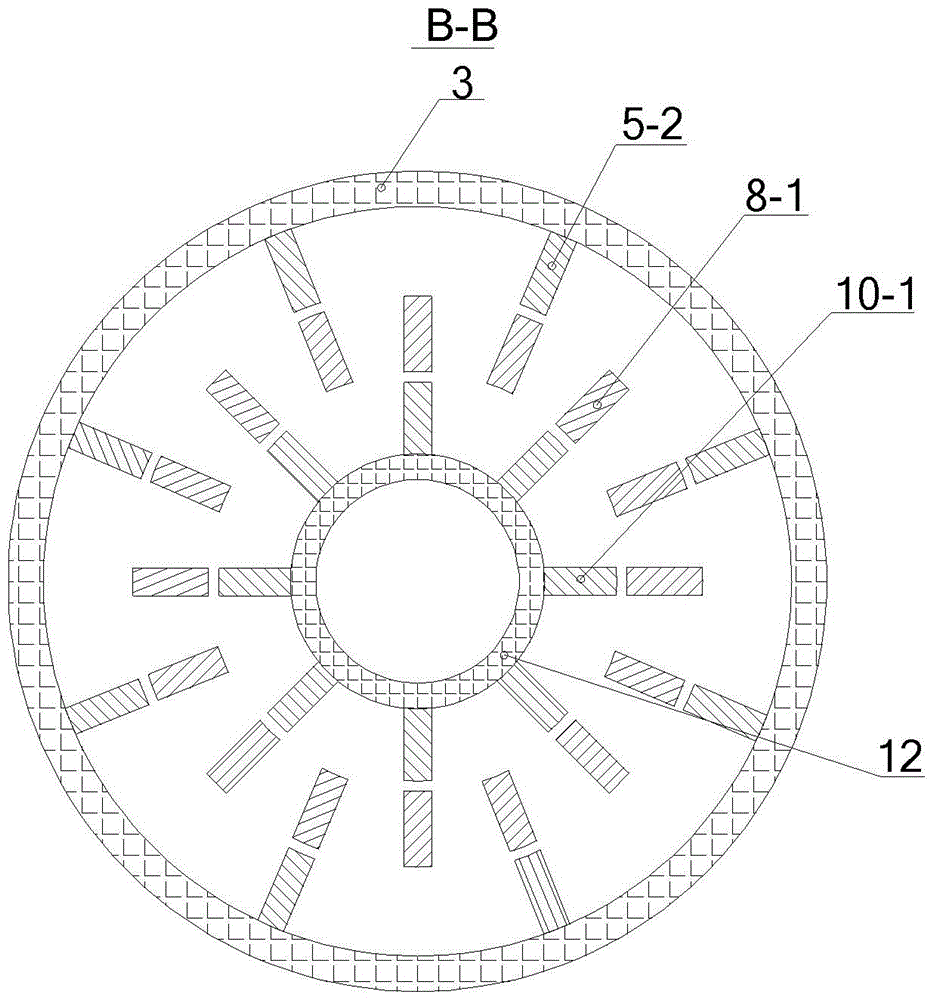

[0022] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment, the rotor magnetic concentration double-stator transverse magnetic field permanent magnet synchronous motor described in this embodiment includes a stator, a rotor, a casing 3 and a rotor support 4, the stator includes an outer stator and an inner stator, and the rotor is located at the outer stator and the inner stator. Between the stators, and fixed on the rotor bracket 4; the first working air gap is formed between the outer stator and the rotor, and the second working air gap is formed between the inner stator and the rotor;

[0023] The outer stator includes an outer stator core 5 and an outer stator armature winding 6, the outer stator core 5 includes p first U-shaped outer stator cores 5-1 and p second U-shaped outer stator cores 5-2, and p first U-shaped outer stator cores 5-1 and p second U-shaped outer stator cores 5-2 are alternately and evenly distribu...

specific Embodiment approach 2

[0040] Specific implementation mode two: the following combination Figure 1 to Figure 5 Describe this embodiment, the rotor magnetic concentration type double-stator transverse magnetic field permanent magnet synchronous motor described in this embodiment includes a three-phase stator, a three-phase rotor, a casing 3 and three rotor supports 4, and each phase stator includes an outer stator and an inner stator The rotor of each phase is located between the outer stator of the phase and the inner stator of the phase, and is fixed on a rotor bracket 4; the first working air gap is formed between the outer stator and the rotor, and the second working air gap is formed between the inner stator and the rotor. Air gap; three-phase stators are arranged side by side along the axial direction;

[0041] The outer stator includes an outer stator core 5 and an outer stator armature winding 6, the outer stator core 5 includes p first U-shaped outer stator cores 5-1 and p second U-shaped o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com