Product fully-opened hard box flatness detection method and device

A detection method, a fully open technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of surface inward depression, no effective monitoring and evaluation of surface flatness, and the upper and lower covers cannot be closed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

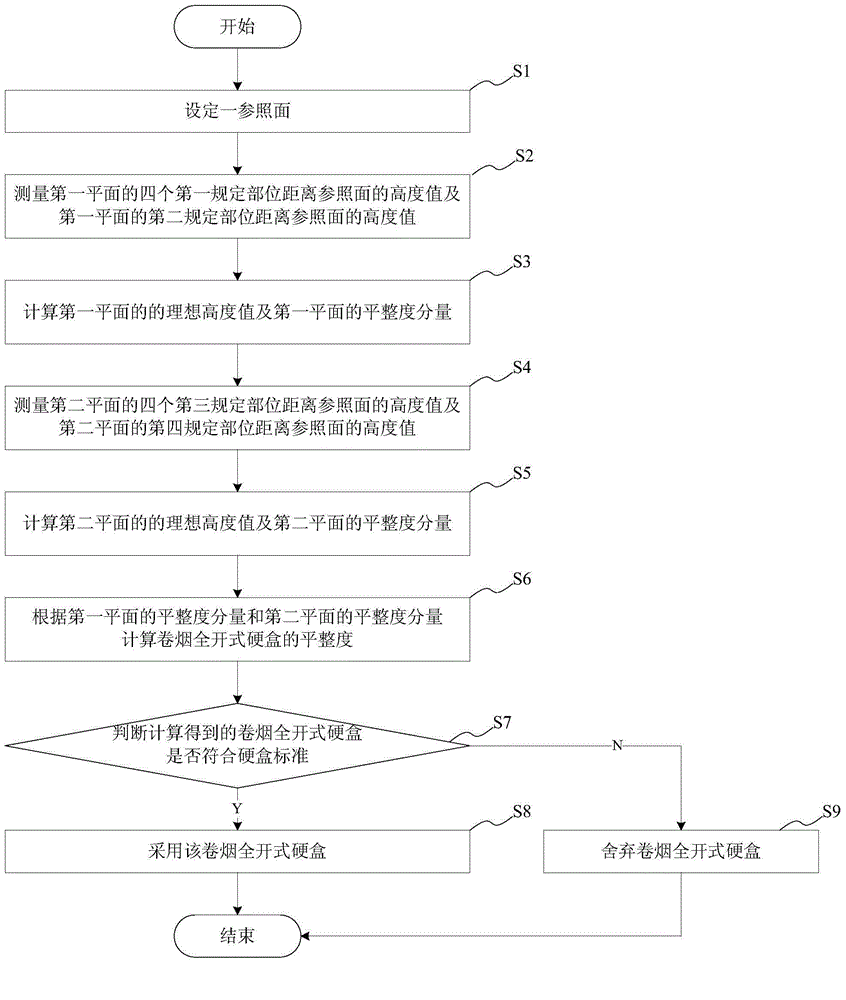

Embodiment 1

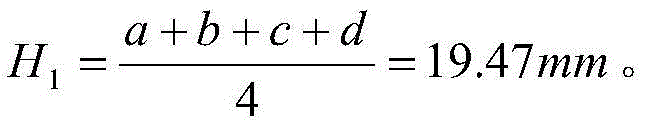

[0032] This embodiment provides a flatness detection method for a fully open hard box of a product, which is applied to a fully open hard box of a product. The fully open hard box of the product includes a first plane and a second plane, and the four corners of the first plane are The part is defined as a first predetermined part, the middle part of the first plane is defined as a second predetermined part, the corners of the second plane are defined as a third predetermined part, and the middle part of the second plane is defined as a fourth predetermined part. In this embodiment, the first plane of the fully open hard box of the product is the front of the fully open hard box of the product, and the second plane of the fully open hard box of the product is the front of the fully open hard box of the product. reverse side of the box. In this embodiment, the fully open hard box of the product is a fully open hard box of cigarettes. see figure 1 , which is a schematic flow ch...

Embodiment 2

[0045] This embodiment provides a flatness testing device for a fully open hard box of a product. The fully open hard box of the product includes a first plane and a second plane, and the four corners of the first plane are defined as the first specified position, and the second plane is defined as the first specified position. The middle part of the first plane is defined as the second predetermined part, the four corners of the second plane are defined as the third predetermined part, and the middle part of the second plane is defined as the fourth predetermined part. In this embodiment, the fully open hard box of the product is a fully open hard box of cigarettes. The flatness detection equipment of the fully open cigarette box includes: a positioning unit, a first fixing unit, a second fixing unit, a third fixing unit, a measuring unit, and a calculating unit.

[0046] The positioning member 1 is used to define a reference plane. In this embodiment, the positioning member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com