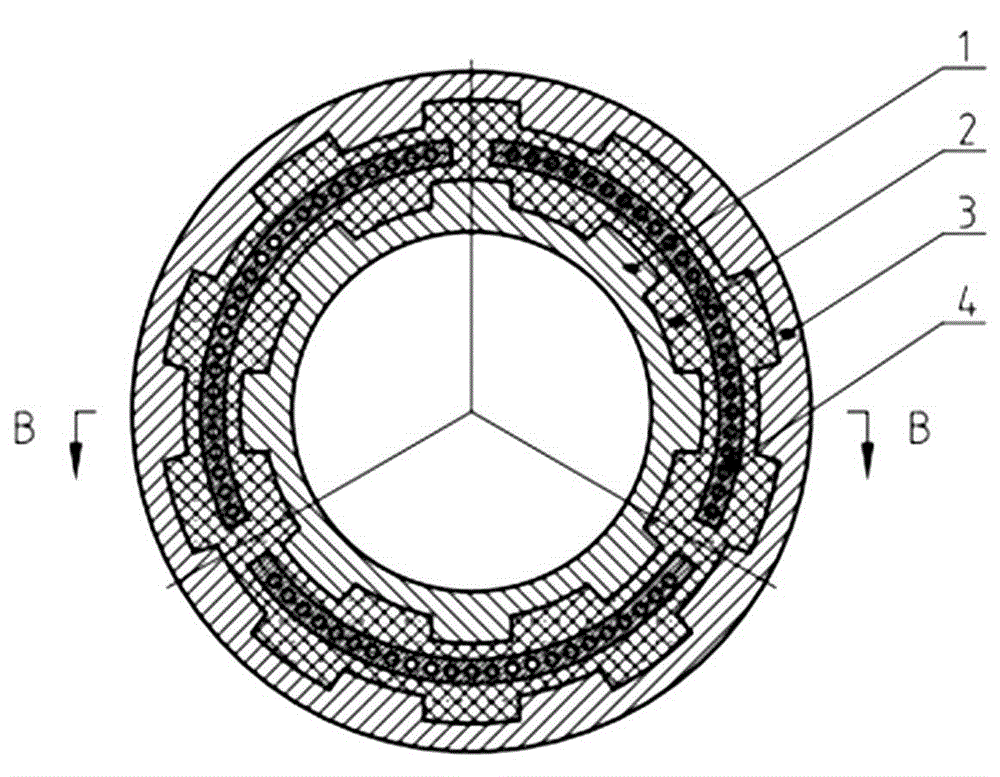

Concave and convex spline type tubular rubber shock absorber with interval expansion variable layer

A rubber shock absorber and spline technology, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of low damping loss factor and general vibration reduction effect, so as to improve the damping loss factor, Good economic and social benefits, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

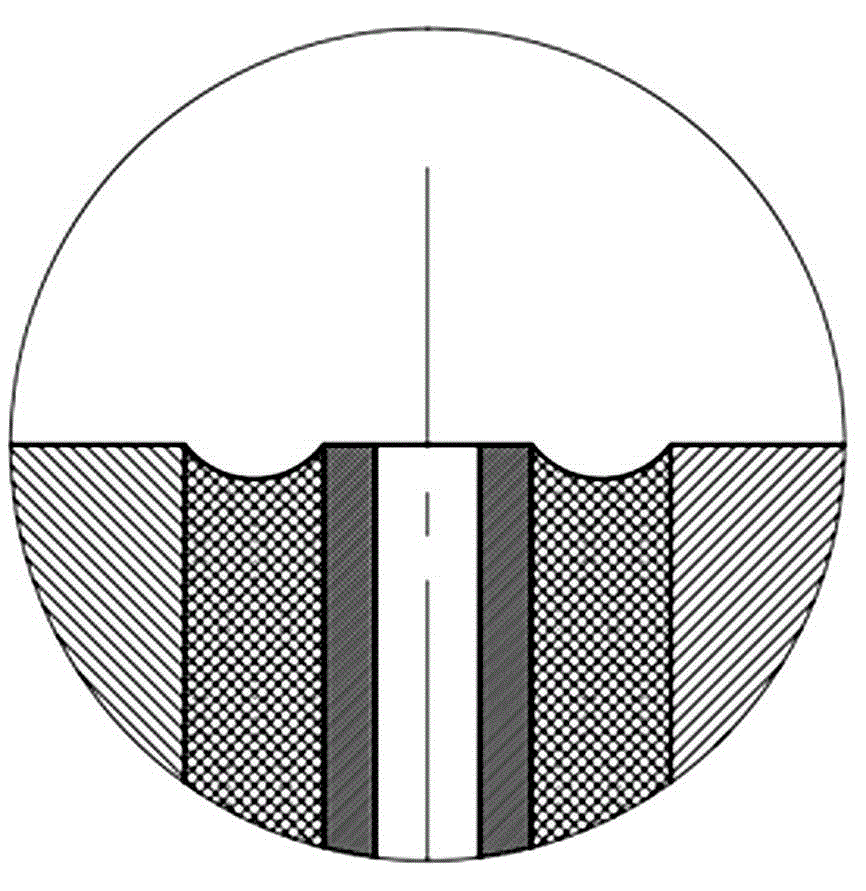

[0036] The inner spline groove is machined on the inner surface of the outer ring of the shock absorber, and the outer spline groove is machined on the outer surface of the inner ring; the interval expansion layer is three equal diameters uniformly arranged in the circumferential direction. / 3-turn structure, through holes are machined in the axial direction (according to specific production conditions, the interval expansion layer 4 appropriately adopts a split structure: that is, along the arc-shaped connection of the center of the cross section of these through holes, the interval expansion layer 4 Divide the inner and outer layers into separate stamping forming, and then weld them into a whole, which is convenient for processing and manufacturing and reduces costs); the rubber layer 2 mixes the rubber compound with an appropriate amount of metal particles and metal wires evenly, and the metal wires are arranged along the axial direction as far as possible , The above parts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com