Abutment reaming hole construction for optimizing deformation capability of integral abutment bridge

An integral abutment and abutment technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of less rigid connections, inability to transmit force, and lack of flexibility, so as to improve the ability to withstand strong external impacts and The performance of the reaction force of the bridge structure, the load-bearing capacity will not decrease, and the effect of the force transmission structure will be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

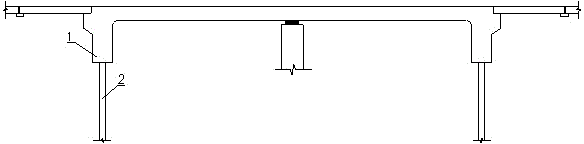

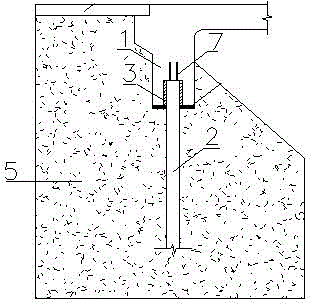

[0032] When the abutment reaming structure adopts such as Figure 4 The sliding connection shown, in daily use, the bridge is slowly deformed in the horizontal direction due to the temperature load, and its deformation pressure acts on the support pile 2 through the abutment reaming hole 30 of the abutment 1, because the abutment reaming hole 30 and the support There is a deformation layer 3 between the piles 2. The deformation layer 3 first produces elastic deformation under huge pressure, and disperses the pressure to reduce the horizontal load borne by the supporting pile 2. Since the material of the deformation layer 3 has certain fluidity, the deformation layer 3 Under the huge pressure slowly produced by the temperature deformation of the bridge, the material in the deformation layer 3 in the direction of the pressure is gradually squeezed to the side and redistributed, resulting in plastic deformation. The horizontal deformation of the main body is compensated, so that ...

Embodiment 2

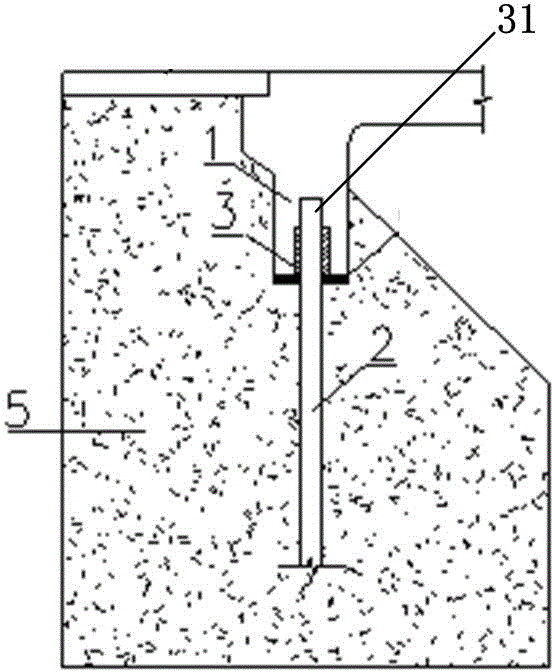

[0034] When the abutment reaming structure adopts such as image 3 As shown in the hinge joint, when an earthquake occurs, the bridge vibrates rapidly and greatly, and the vibration acts on the supporting pile 2 through the abutment reaming hole 30 of the abutment 1, because there is a deformation layer between the abutment reaming hole 30 and the supporting pile 2 3. Due to its elastic characteristics, the deformation layer 3 produces reciprocating deformation under a huge reciprocating load and effectively absorbs the load. The material of the deformation layer 3 has certain fluidity, which can disperse the impact force generated by huge vibrations, and effectively reduce the reciprocating load of the concrete pile foundation. Destruction under load. At this time, the connecting steel bar 7 at the top of the supporting pile 2 is deformed under the action of torsion, and the reciprocating load generated at the steel bar 7 due to the earthquake is eliminated by deformation, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com