Processing method for endowing surface of protein fabric with anti-microbial and anti-static performance

A processing method and protein technology, which can be used in fiber processing, animal fibers, textiles and papermaking, etc., can solve the problem of high price of silver, and achieve the effect of low cost and increased added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A treatment method for making the surface of worsted wool fabric have antibacterial and antistatic properties, the specific steps are:

[0032] (1) Pretreatment

[0033] a. Take 2g of worsted wool fabric and ultrasonically clean it in ethanol solution for 10 minutes;

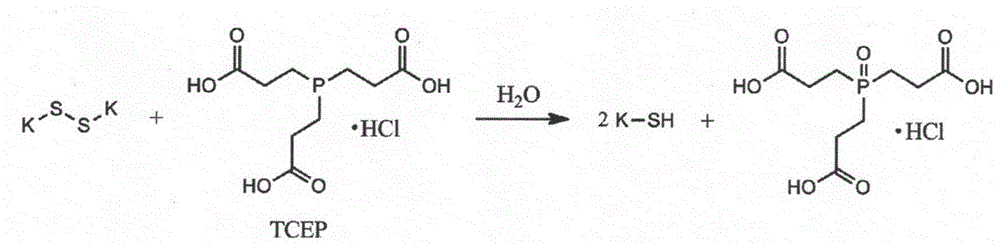

[0034] b. Take 0.65g TCEP solid powder, put it in a 150ml beaker, add 100mL water / ethanol (1:1) solution, stir well, use Na 2 CO 3 / NaHCO 3 As a buffer solution, adjust the pH value of the solution to 7;

[0035] c. Immerse the wool fabric in the TCEP treatment solution, and seal the mouth of the beaker with a plastic film;

[0036] d. Place the beaker in a constant temperature magnetic stirring water bath and treat it at 25°C for 4 hours;

[0037] e. Take out the wool fabric, wash it thoroughly with deionized water, and dry it.

[0038] (2) Finishing

[0039] f. Take 5 g of GTAC and dissolve it in 100 mL of water / ethanol (1:1) solution to make a treatment solution containing 5% GTAC;

[0040] g. ...

Embodiment 2

[0044] A treatment method for making the surface of woolen wool fabric have antibacterial and antistatic properties, the specific steps are:

[0045] (1) Pretreatment

[0046] a. Get 4g of woolen woolen fabric and ultrasonically clean it in ethanol solution for 10 minutes;

[0047] b. Take 1.2g TCEP solid powder, place it in a 250ml beaker, add 200mL water / ethanol (1:1) solution, stir well, use Na 2 CO 3 / NaHCO 3 As a buffer solution, adjust the pH value of the solution to 7;

[0048] c. Immerse the wool fabric in the TCEP treatment solution, and seal the mouth of the beaker with a plastic film;

[0049] d. Place the beaker in a constant temperature magnetic stirring water bath and treat it at 25°C for 4 hours;

[0050] e. Take out the wool fabric, wash it thoroughly with deionized water, and dry it.

[0051] (2) Finishing

[0052] f. Take 10 g of GTAC and dissolve it in 200 mL of water / ethanol (1:1) solution to make a treatment solution containing 5% GTAC;

[0053]g. ...

Embodiment 3

[0057] A treatment method for making the surface of silk fabric have antibacterial and antistatic properties, the specific steps are:

[0058] (1) Pretreatment

[0059] a. Take 2g of silk fabric and ultrasonically clean it in ethanol solution for 10 minutes;

[0060] b. Take 0.65g TCEP solid powder, put it in a 150ml beaker, add 100mL water / ethanol (1:1) solution, stir well, use Na 2 CO 3 / NaHCO 3 As a buffer solution, adjust the pH value of the solution to 7;

[0061] c. Immerse the silk fabric in the TCEP treatment solution, and seal the mouth of the beaker with a plastic film;

[0062] d. Place the beaker in a constant temperature magnetic stirring water bath and treat it at 25°C for 4 hours;

[0063] Take out the silk fabric, fully wash it with deionized water, and dry it.

[0064] (2) Finishing

[0065] f. Take 5 g of GTAC and dissolve it in 100 mL of water / ethanol (1:1) solution to make a treatment solution containing 5% GTAC;

[0066] g. Use Na 2 CO 3 / NaHCO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com