Method for preparing fatty acid by fermenting lignocellulose ionic liquid hydrolysate

An ionic liquid and fatty acid technology, applied in the field of microbial fermentation, can solve problems such as unreported fatty acids, and achieve the effects of alleviating the shortage of petrochemical resources, regulating sugar prices, and preventing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

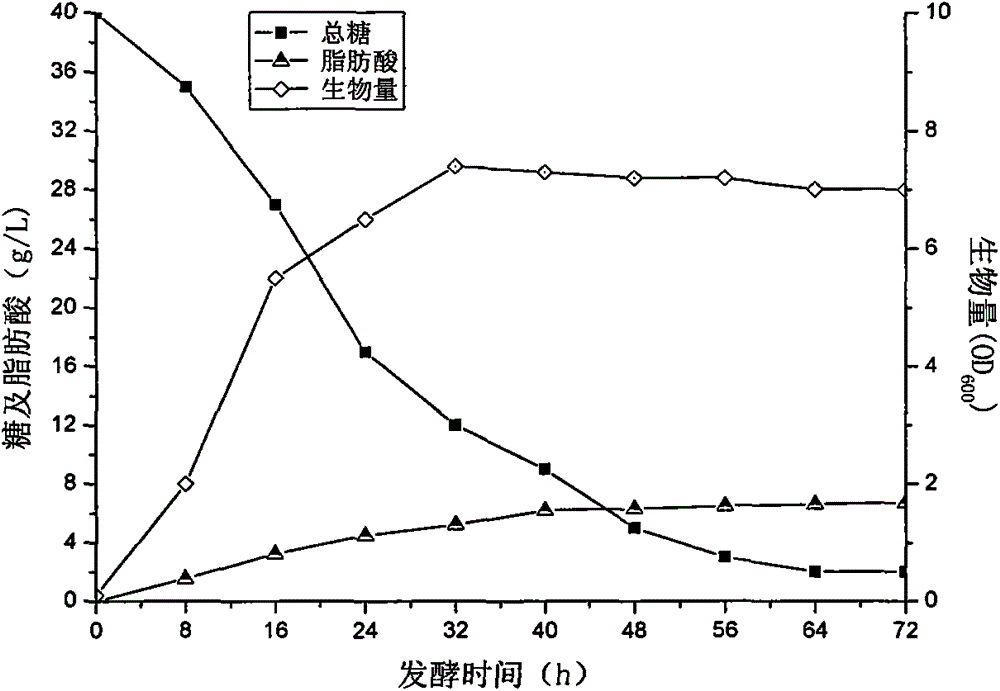

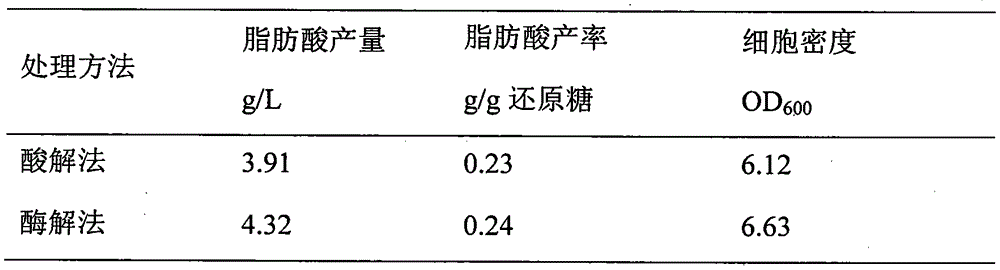

[0039] Effects of hydrolyzate obtained by different treatment methods on the production of fatty acids by fermentation of bamboo powder

[0040] The bamboo powder is hydrolyzed by ionic liquid through acid hydrolysis method and enzymatic hydrolysis method to obtain lignocellulose hydrolyzate.

[0041] (1) Acid hydrolysis method: After a sufficient amount of ionic liquid is melted, stir and react with bamboo powder, cupric chloride and 10% (v / v) hydrochloric acid at 100°C for 4-5 hours, add 50% (w / w) hydrogen after suction filtration Sodium oxide made it layered, mixed quickly for 30 minutes, and the supernatant obtained by rapid centrifugation with a centrifuge was the hydrolyzate used for fermentation.

[0042] (2) Enzyme hydrolysis method: After a sufficient amount of ionic liquid and bamboo powder are stirred and reacted at 120°C for 3 hours, add water to filter, and wash with water 4 to 6 times to obtain treated cellulose, dry at 80°C for 6 hours, and then add cellulase R...

Embodiment 2

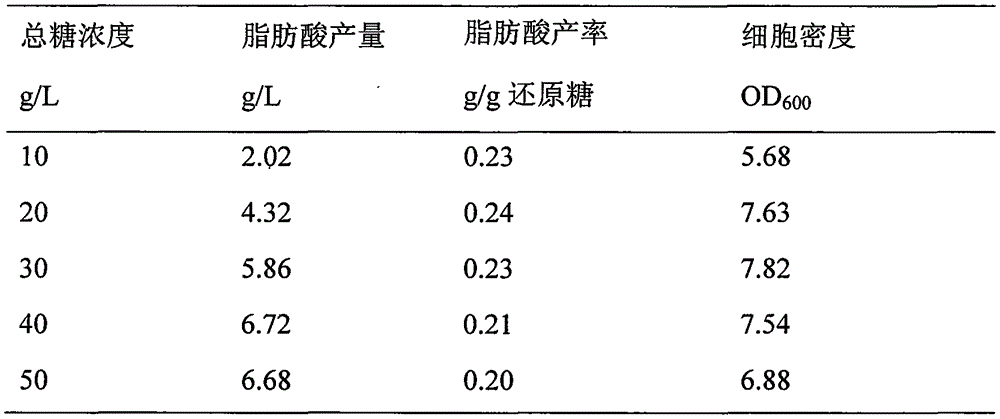

[0048] Effects of different initial total sugar concentrations on fatty acid production from lignocellulose hydrolyzate

[0049] Use enzymatic hydrolysis method to obtain lignocellulose ionic liquid hydrolyzate: a sufficient amount of ionic liquid and bamboo powder are stirred and reacted at 120°C for 3 hours, then add water for suction filtration, and wash with water for 4 to 6 times to obtain treated cellulose, and dry at 80°C for 6 hours Afterwards, cellulase was added to react for 24 hours in an acetic acid-sodium acetate buffer solution with a pH of 4.8. The hydrolyzate obtained by suction filtration is used for fermentation.

[0050] Insert the E. coli strain into the seed culture medium, and culture it statically at 37°C for 18-20 hours in an ordinary incubator, and transfer it into a 250mL Erlenmeyer flask containing fermentation medium with different initial total sugar concentrations according to the inoculum size of 8%, and fill it with liquid The volume is 40mL, t...

Embodiment 3

[0055] Effects of Different Nitrogen Sources on Fatty Acid Production by Lignocellulose Hydrolyzate Fermentation

[0056] Use enzymatic hydrolysis method to obtain lignocellulose ionic liquid hydrolyzate: sufficient amount of ionic liquid and bamboo powder are stirred and reacted at 120°C for 3 hours, then add water for suction filtration, and wash with water for 4-6 times to obtain pretreated cellulose, and dry at 80°C After 6 hours, cellulase was added to react for 24 hours in an acetic acid-sodium acetate buffer solution with a pH of 4.8. The hydrolyzate obtained by suction filtration is used for fermentation.

[0057] According to the method for fatty acid production by Escherichia coli strain fermentation in Example 2, the DQ430 strain plate constructed in the laboratory was cultivated in a common box for 24 hours, and then connected to a 30mL seed medium with an inoculation loop, and cultivated at 37°C for 20h, according to 8% The inoculum amount was connected to a 250m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com