A kind of preparation method of polyether modified polycarboxylate grinding aid

A technology of polyether modification and polycarboxylic acid, which is applied in the field of preparation of polycarboxylate grinding aids by modification of methallyl alcohol polyoxyethylene ether, can solve the problem that the effective utilization rate of energy is less than 5%, it is difficult to promote industrialization, and the product Complicated components and other issues, to achieve the effect of strong operability and repeatability, simple preparation process, and low retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

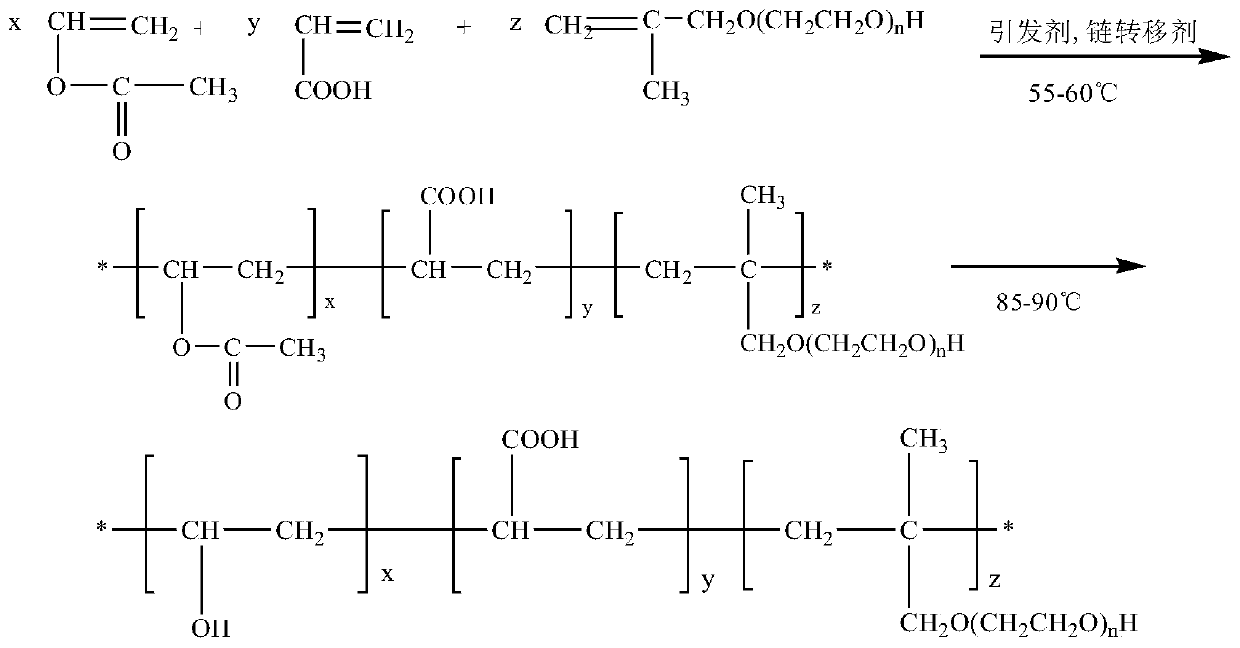

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 (No. HCV-1):

[0026] A kind of preparation method of the polycarboxylate grinding aid of polyether modification, comprises the following steps:

[0027] a. Ingredients: Weigh 0.1mol of methallyl alcohol polyoxyethylene ether (HPEG for short), 0.1mol of acrylic acid, and 0.1mol of vinyl acetate, and weigh the mixture of methallyl alcohol polyoxyethylene ether, acrylic acid and vinyl acetate. The initiator ammonium persulfate of total mass consumption 1.5% (that is: the mass consumption of initiator ammonium persulfate is 1.5% of the total mass consumption of the sum of methallyl alcohol polyoxyethylene ether, acrylic acid and vinyl acetate), weighed Get methallyl alcohol polyoxyethylene ether, acrylic acid and vinyl acetate in a total mass amount of 0.5% chain transfer agent mercaptoethanol (that is: the mass amount of chain transfer agent mercaptoethanol is methallyl alcohol polyoxyethylene ether, 0.5% of the total mass consumption of the sum of acrylic a...

Embodiment 2~10

[0031] Embodiments 2 to 10 (the numbers are respectively corresponding HCV-2 to HCV-10):

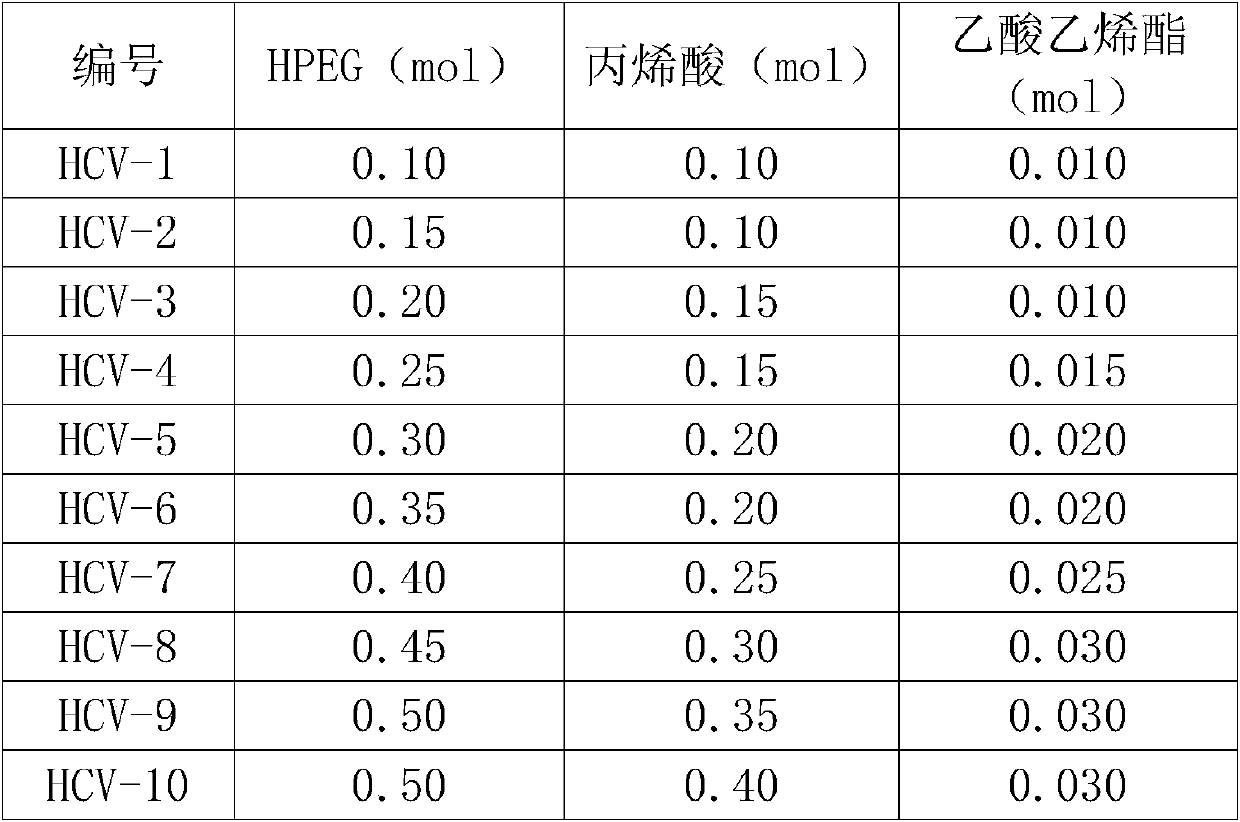

[0032] A kind of preparation method of the polycarboxylate grinding aid of polyether modification, each embodiment weighs the consumption of HPEG, acrylic acid, vinyl acetate respectively according to the raw material of Table 1 and proportioning, fixes the consumption of mercaptoethanol and ammonium persulfate respectively It is 0.5% and 1.5% of the total mass of the monomers (the total mass of the monomers is the sum of methallyl alcohol polyoxyethylene ether, acrylic acid and vinyl acetate) 0.5% and 1.5%, and the other and the preparation process are the same as the method in Example 1, Omit; prepare the polycarboxylate grinding aid of 9 kinds of polyether modification of embodiment number HCV-2~HCV-10:

[0033] Table 1: Raw material proportions of Examples 1-10:

[0034]

Embodiment 1~10

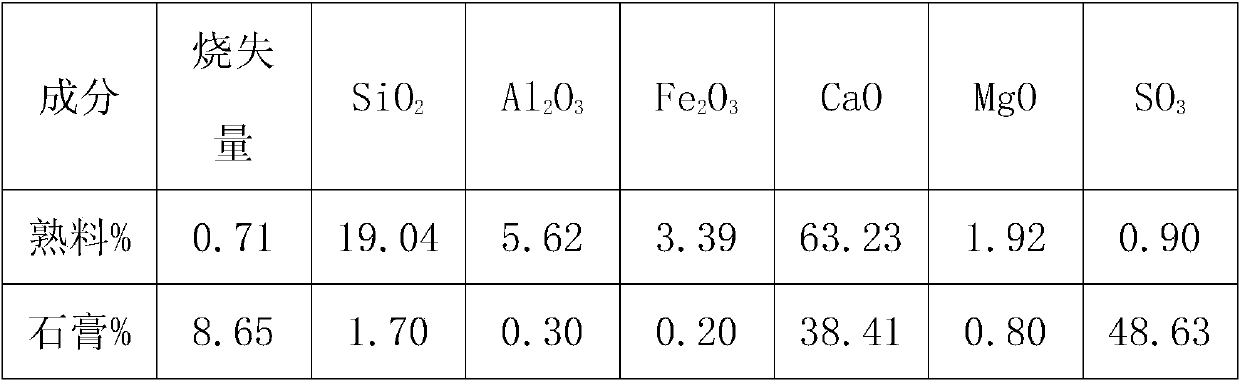

[0035] The modified HPEG polycarboxylate grinding aid that embodiment 1~10 (numbering HCV-1~HCV-10) obtains and HPEG (all being mixed with the solution that mass percent concentration is 40%) carry out small grinding test; Test cement Both clinker and gypsum came from a cement plant in Jiangyou, Sichuan, and their chemical composition and mass percentage are shown in Table 2.

[0036] Table 2: Clinker and Gypsum Chemical Composition

[0037]

[0038] Use a jaw crusher to crush the clinker and gypsum with a mass ratio of 95:5 to less than 5mm, weigh 4kg of raw materials, drop the weighed grinding aid evenly on the raw materials, and then pour the raw materials into In the experimental small mill, the grinding time was 20 minutes, and the unloading was 5 minutes. The dosage of grinding aid is set to 0.05%, and a control group is set. The ground cement is passed through a 0.9mm square hole sieve, and then performance testing is carried out.

[0039] According to the provis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com