Novel lightweight composite heat-insulation ceramic construction material and preparation method thereof

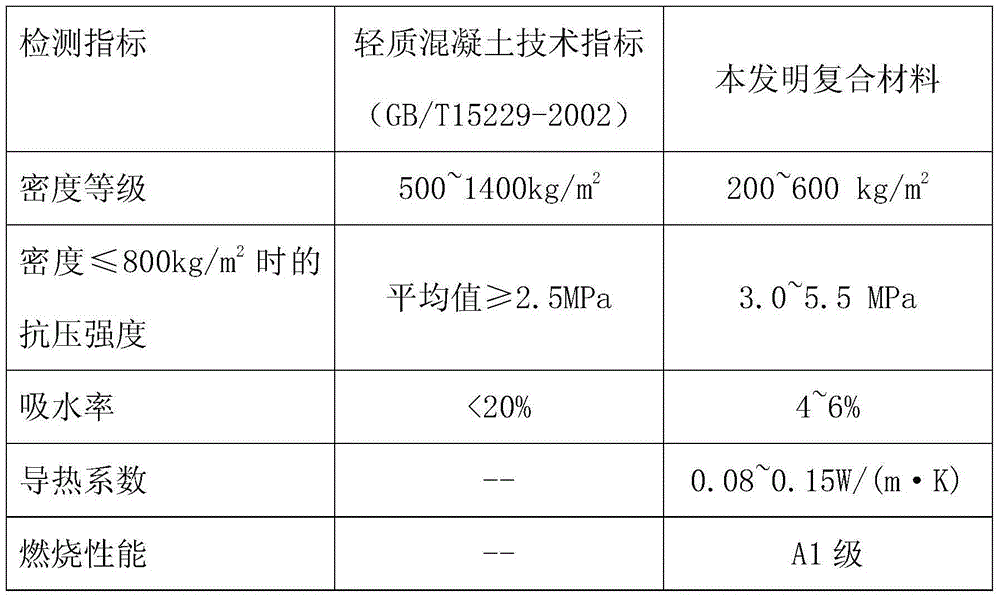

A technology of lightweight ceramics and composite thermal insulation, applied in the field of building materials, can solve the problems of sustainable development of the ceramic industry, poor stability and durability, waste residues occupying public resources, etc., which limit the development of urban economy, and achieve remarkable thermal insulation effects. Long service life, good sound absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: A new lightweight ceramic composite thermal insulation building material, its main raw materials are: 55 parts of waste ceramic materials, 15 parts of calcium carbonate-based waste materials, 10 parts of clay, 15 parts of bentonite, and 8 parts of foaming agent.

[0022] In this embodiment, the calcium carbonate-based waste material is marble powder, and the particle size of the marble powder is 100-200 mesh; the foaming agent is calcium carbonate salt, and the particle size of the calcium carbonate salt is 200-800 mesh.

[0023] The preparation method of the novel lightweight ceramic composite thermal insulation building material comprises the following steps:

[0024] a. Pulverization: Mix 55 parts of waste ceramic materials, 15 parts of calcium carbonate-based waste materials, 10 parts of clay, 15 parts of bentonite, 2 parts of lauryl amine oxide and 100 parts of water, and use wet ball milling to dry the mixture And pass through a 30-mesh sieve. After the...

Embodiment 2

[0027] Example 2: A new lightweight ceramic composite thermal insulation building material, its main raw materials are: 40 parts of waste ceramic materials, 5 parts of calcium carbonate-based waste materials, 1 part of clay, 2 parts of bentonite, and 6 parts of foaming agent.

[0028] In this embodiment, the calcium carbonate-based waste is limestone powder with a particle size of 100-200 mesh; the foaming agent is graphite powder with a particle size of 200-800 mesh.

[0029] The preparation method of the novel lightweight ceramic composite thermal insulation building material comprises the following steps:

[0030] a. Pulverization: Mix 40 parts of waste ceramic materials, 5 parts of calcium carbonate-based waste materials, 1 part of clay, 2 parts of bentonite, 1 part of lauryl amine oxide and 60 parts of water, and use wet ball milling to dry the mixture And pass through a 30-mesh sieve. After the sieve, the raw materials are sprayed and granulated, and passed through a 60-...

Embodiment 3

[0033] Example 3: A new lightweight ceramic composite thermal insulation building material, its main raw materials are: 45 parts of waste ceramic materials, 10 parts of calcium carbonate-based waste materials, 5 parts of clay, 8 parts of bentonite, and 7 parts of foaming agent.

[0034] In the present embodiment, the calcium carbonate-based waste material is a mixture of marble powder and limestone powder, and the particle size of the calcium carbonate-based waste material is 100 to 200 mesh; the foaming agent is graphite powder, and the particle size of the graphite powder is 200 mesh. ~800 mesh.

[0035] The preparation method of the novel lightweight ceramic composite thermal insulation building material comprises the following steps:

[0036] a. Pulverization: Mix 45 parts of waste ceramic materials, 10 parts of calcium carbonate-based waste materials, 5 parts of clay, 8 parts of bentonite, 1 part of lauryl amine oxide and 80 parts of water, and use wet ball milling to dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com