Machining method of wedge-groove gauge

A processing method and gauge technology, applied to measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of inaccurate measurement, complicated operation of measuring the machining accuracy of the dovetail groove of the wheel disc, etc., so as to ensure accuracy and facilitate clamping and alignment , The effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

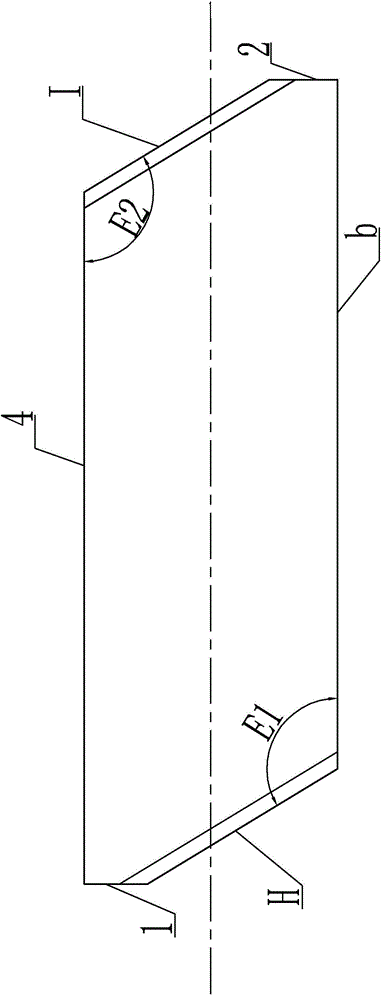

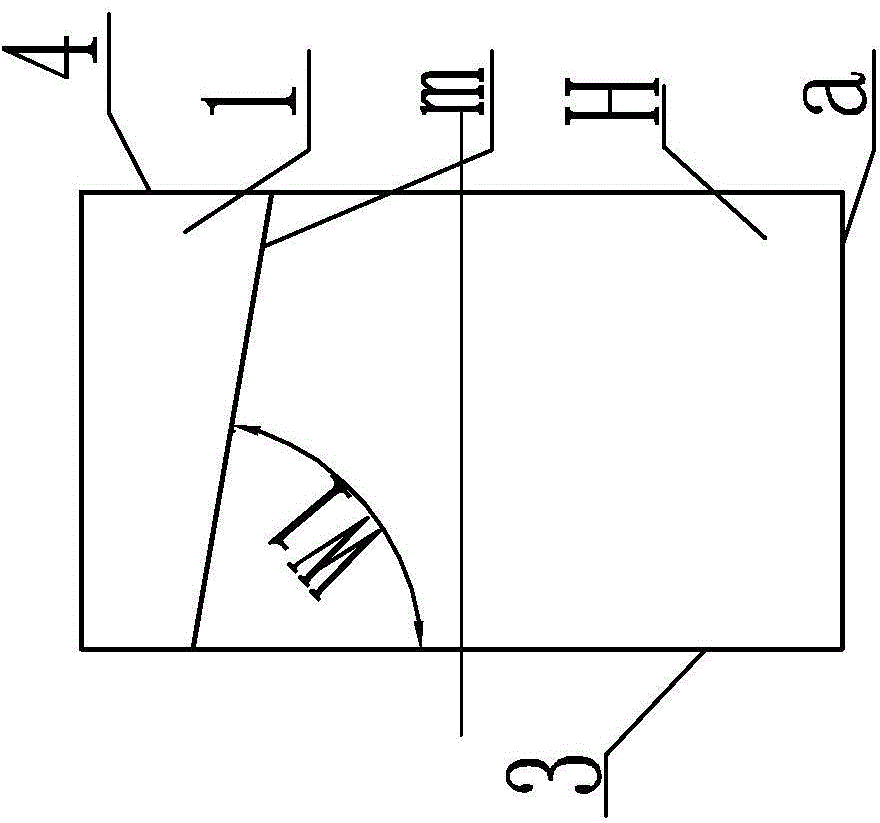

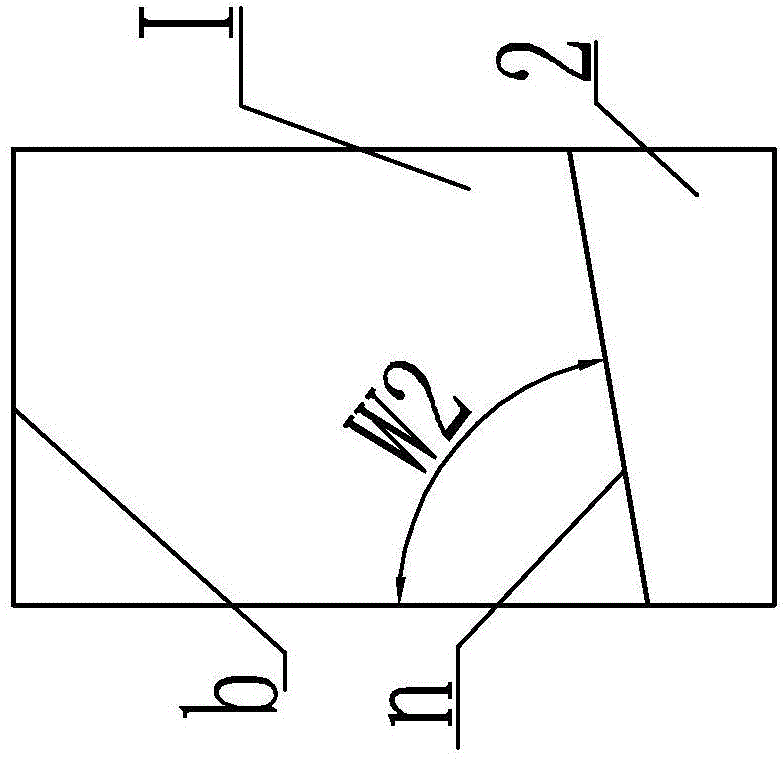

[0014] Specific implementation mode one: combine Figure 1-Figure 12 Describe this embodiment, the processing method of a kind of wedge groove gauge described in this embodiment, described method is realized according to the following steps:

[0015] Step 1: blanking: select the cuboid blank, the length of the blank is 230mm, the width of the blank is 80mm, and the height of the blank is 50mm;

[0016] Step 2: Rough milling: use a milling machine to process the blank until the length, width and height are respectively 222.2mm, 70.2mm and 42.2mm;

[0017] Fine grinding: Use a grinder to fine-grind the blank. The dimensional accuracy after fine grinding is 222±0.01 in length, 70±0.01 in width and 42±0.01 in height;

[0018] Step 3: End face milling: use a CNC milling machine to mill the two ends of the blank, process a first slope (H) on the first end face (1) of the blank, and process a second slope (H) on the second end face (2) of the blank ( I), the first slope (H) is para...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination Figure 1-Figure 12 Describe this embodiment, the processing method of a kind of wedge groove gauge described in this embodiment, described method is realized according to the following steps:

[0022] Step 6: According to step 5, the connection between each second raised slope 7 and the bottom surface C of the workpiece is processed with a rounded corner, the radius of the rounded corner is 0.4mm, and the workpiece of the wedge groove gauge is finished. Others and specific implementation methods One is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com