A Venturi Reactor for Sour Gas Treatment

A technology of reactors and reaction tubes, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as inability to produce valuable fuming sulfuric acid, production cycle cannot be guaranteed, and equipment cannot operate normally, so as to prevent excessive Evaporation, safe operation and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

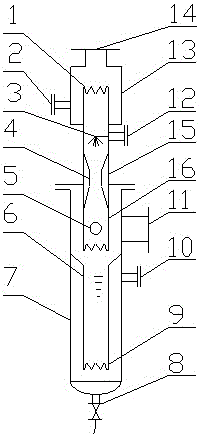

[0024] Such as figure 1 As shown, the present invention provides a kind of Venturi acid gas reactor, and described reactor is divided into three sections from top to bottom, and upper section is liquid phase storage tank 13, and middle section is straight cylinder reaction tube 15, and from top to bottom is inlet and outlet successively. Feed section 1, contraction section 4, throat section 17, expansion section 18 and discharge section 16, the lower section is a liquid-sealed cylinder with a lower end discharge opening 8, and the liquid-sealed cylinder includes a liquid-sealed inner cylinder 6 and a liquid-sealed outer cylinder 7; The upper part of the section forms a set structure with the liquid phase storage tank, and the lower part of the discharge section forms a set structure with the liquid seal cylinder. The upper end of the liquid phase storage tank is provided with a gas phase inlet 14, and the side wall of the liquid phase storage tank is provided with a circulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com