Medical puncture needle with spiral type microstructure and manufacturing method thereof

A puncture needle and micro-texture technology, applied in the direction of puncture needles, trocars, etc., can solve problems such as poor stability, inability to effectively maintain the lubrication effect for a long time, uneven adsorption of lubricants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

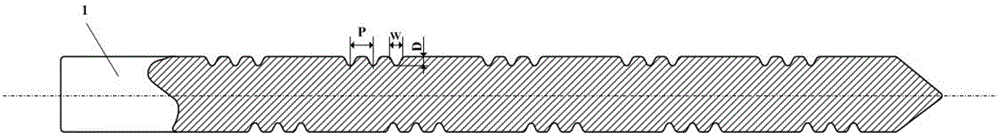

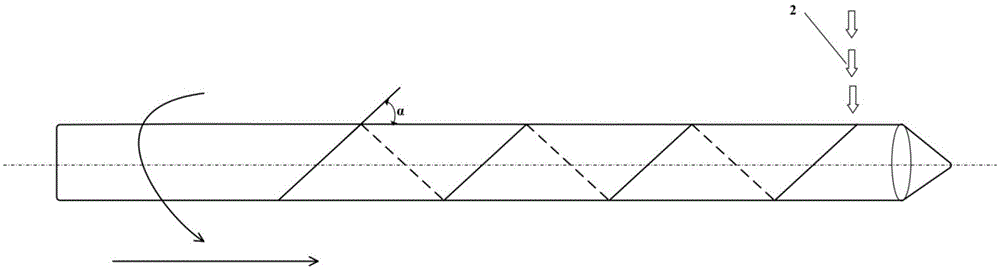

[0015] A preparation of a medical puncture needle with a helical micro-texture, the puncture needle 1 is a medical 316 stainless steel biopsy puncture needle, the micro-textured groove width W is about 80nm, the groove depth D is about 20nm, and the groove spacing P is about 300nm , the angle α between the helix and the axis of the puncture needle is about 70°. Its preparation method is as follows:

[0016] (1) Polish the surface of the puncture needle made of 316 stainless steel to remove the surface contamination layer, and ultrasonically clean it in deionized water for 20 minutes, then immerse the puncture needle in absolute ethanol, and use ultrasonic cleaning for 20 minutes to clean the surface;

[0017] (2) Clamp the puncture needle in the femtosecond laser processor system, keep the femtosecond laser pulse 2 fixed, adjust the energy of the laser pulse to 1 μJ, the frequency to 500 Hz, scan once, and use the rotation and feed movement of the puncture needle to Spiral mi...

example 2

[0021] A preparation of a spiral micro-textured medical puncture needle. The puncture needle 1 is a medical injection needle made of tungsten. The angle α between the line and the axis of the injection needle is about 50°. Its preparation method is as follows:

[0022] (1) Polish the surface of the injection needle made of tungsten to remove the surface contamination layer, and ultrasonically clean it in deionized water for 20 minutes, then immerse the puncture needle in absolute ethanol, and use ultrasonic cleaning for 20 minutes to clean the surface;

[0023] (2) Clamp the injection needle in the femtosecond laser processor system, keep the femtosecond laser pulse 2 fixed, adjust the laser pulse energy to 1.5 μJ, the frequency to 1000 Hz, scan twice, and use the rotation and feed movement of the injection needle Process the helical micro-texture covering the surface of the puncture needle;

[0024] (3) The puncture needle after surface laser texturing was ultrasonically cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com