Multifunctional tobacco leaf fine selection device

A multi-functional tobacco leaf technology, applied in the field of sorting tobacco leaves, can solve the problems of turbulent air flow, high difficulty in identifying tobacco leaves, random flying, etc., and achieve the effect of avoiding spinning and comprehensive image recognition without dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

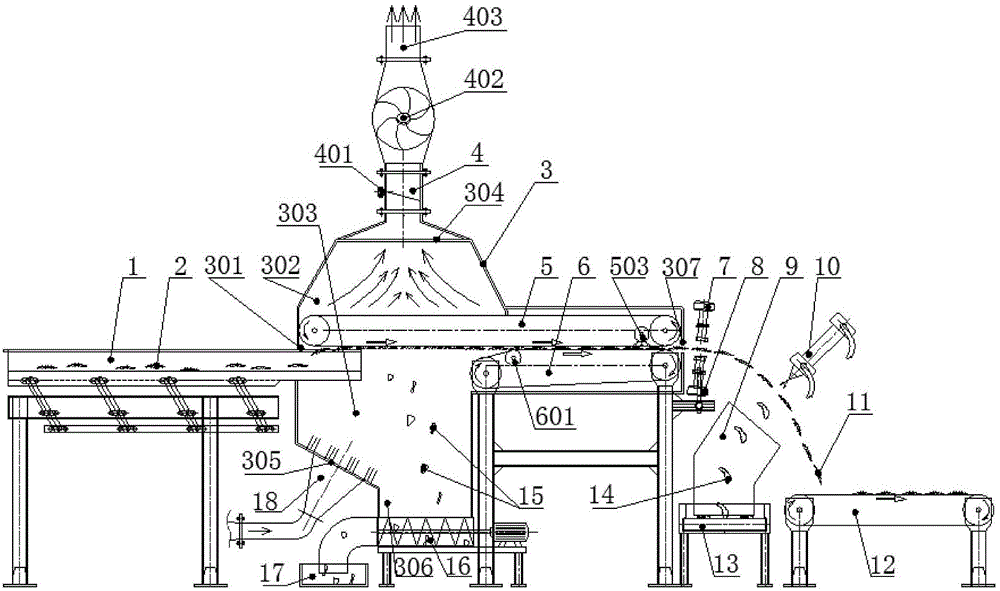

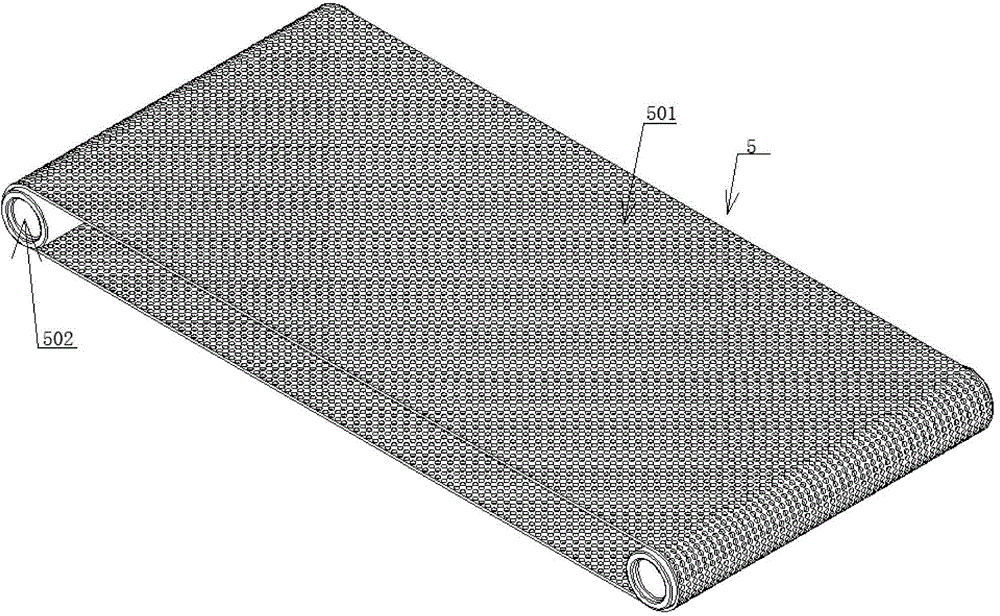

[0022] See figure 1 , a multifunctional tobacco leaf selection device, the present invention is characterized in that it includes a tobacco leaf feeding device 1, a sorting box 3 connected above the end of the feeding device 1, and a negative pressure fan device 4 installed at the upper end of the sorting box 3 , cover the high-speed mesh belt conveyor 5 inside the sorting box 3 and the high-speed belt conveyor 6 below the output end of the high-speed mesh belt conveyor 5, and the screw conveyor installed at the miscellaneous outlet 305 at the bottom of the sorting box 3 16. The foreign matter storage box 17 connected with the screw conveying device 16 is arranged on the positive pressure air inlet duct 18 on the lower left side of the sorting box 3; the first imaging device 7 is respectively installed above and below the outlet of the sorting box 3 , the second imaging device 8, and is provided with the second airflow blowing device 10 to align with the discharge port, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com