Method of producing and distributing liquid natural gas

A technology of liquid natural gas and natural gas, applied in refrigeration and liquefaction, liquefaction, gas fuel and other directions, can solve the problems of high energy consumption and high investment in large factories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

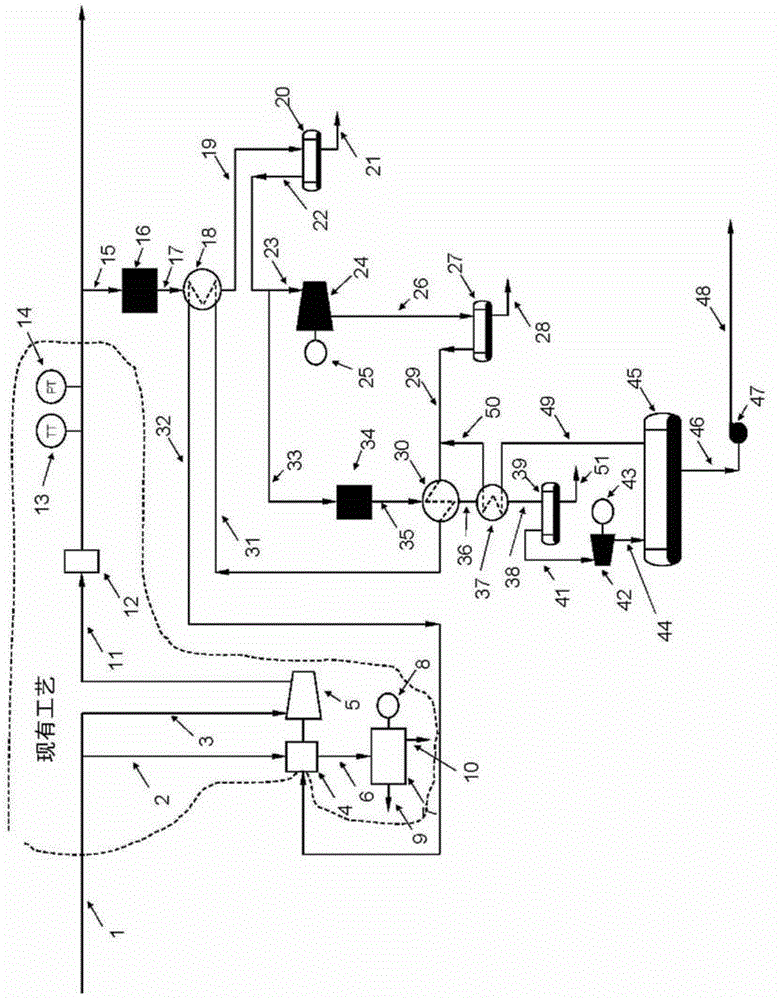

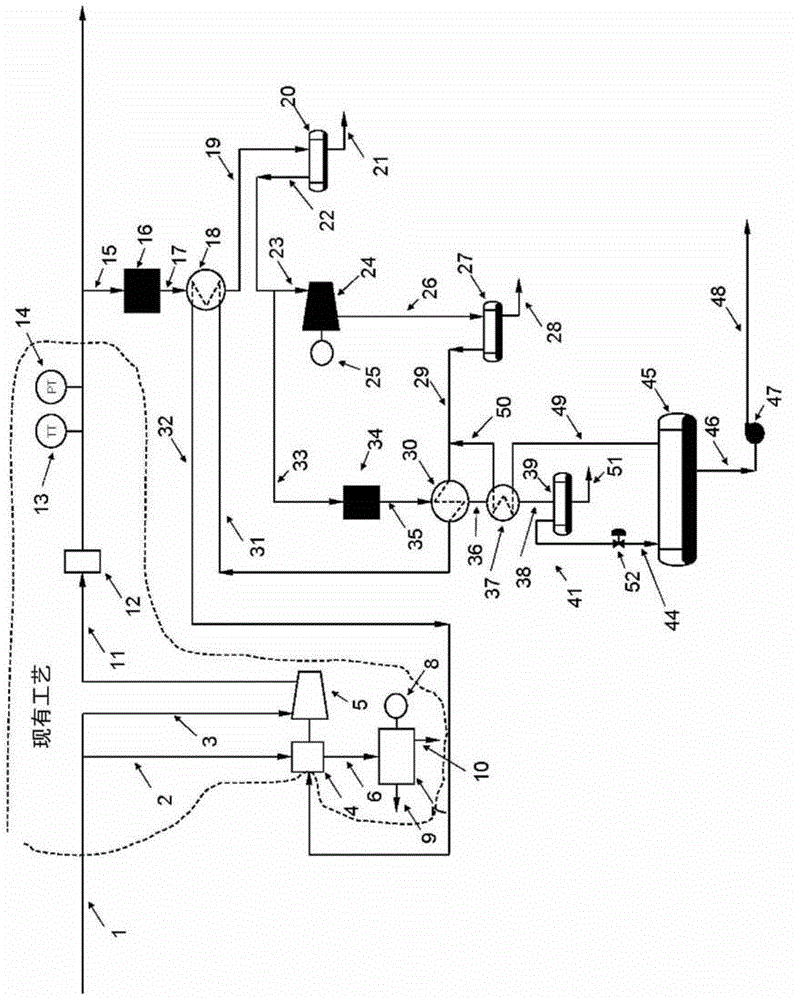

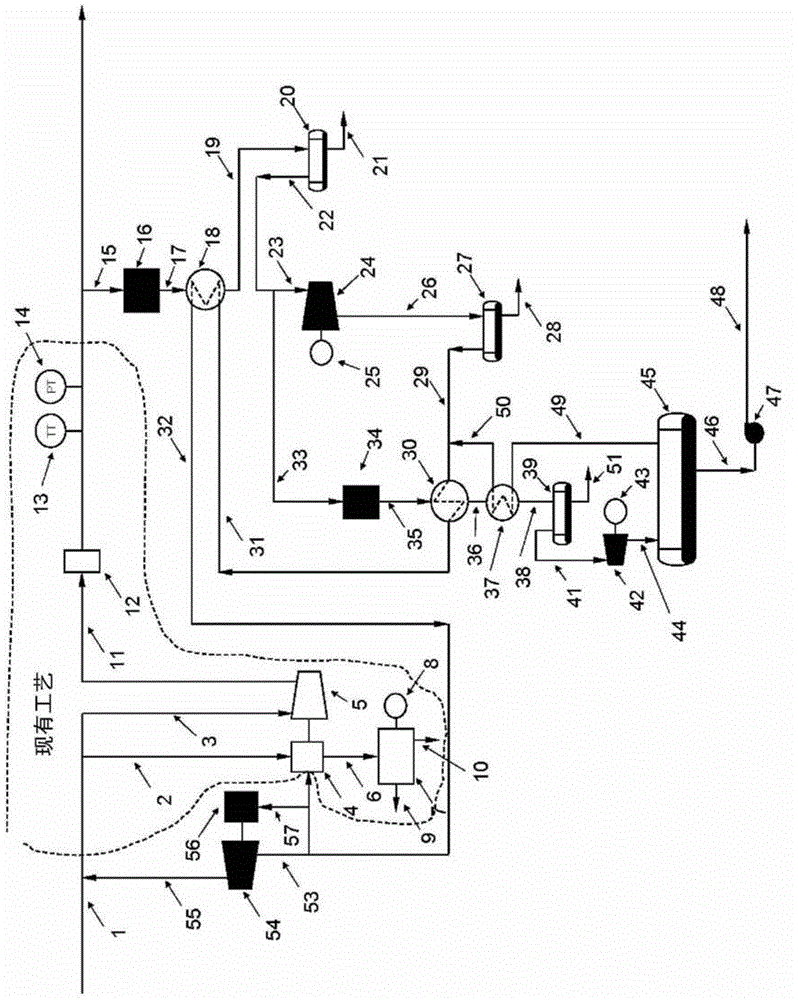

[0012] The following description of the method of producing and distributing LNG will refer to Figure 1 to Figure 5 . The method was developed to produce LNG at compressor stations along natural gas transmission pipelines. This method enables the economical production of LNG at different geographically distributed locations.

[0013] As mentioned above, the method was developed to produce LNG from natural gas compressor stations located on a network of natural gas transmission pipelines. The process utilizes the pressure differential between the high pressure line consumed by the mechanically driven motor at the transfer line compressor station and the low pressure fuel gas stream. The present invention enables small to medium scale LNG production at any gas compression station along the pipeline system. The ability to produce LNG close to the market offers significant advantages in terms of cost compared to existing logistics systems involving large-scale centralized prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com