Compact-type rotor structure with rotor wind path

A rotor structure and compact technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve problems such as unreasonable design of air circuit structure, affecting the service life of the motor, and unfavorable axial space dimensions of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

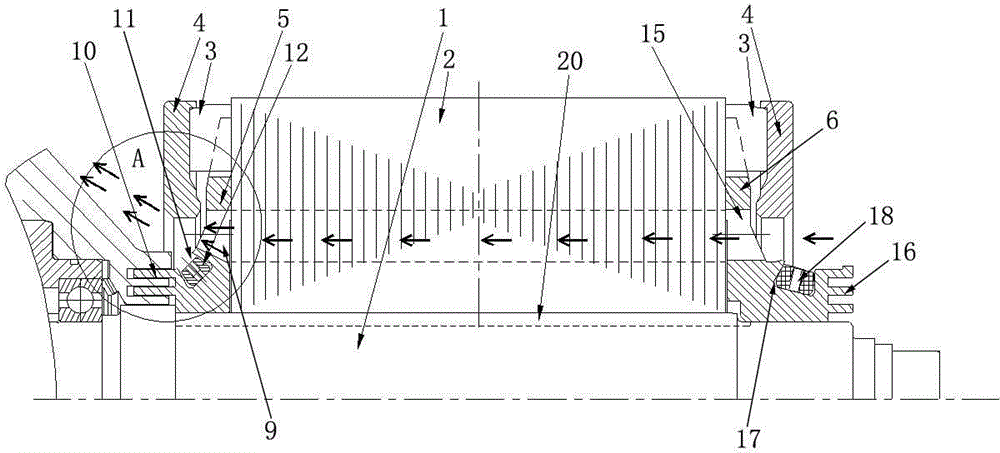

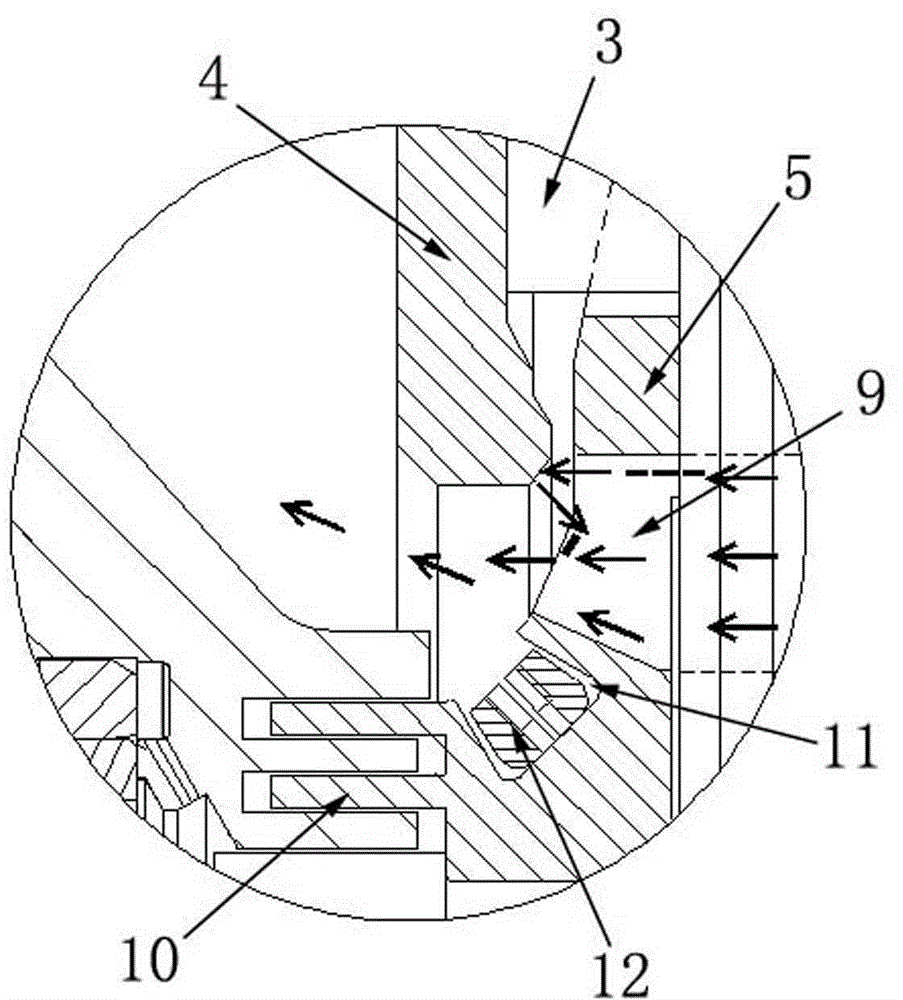

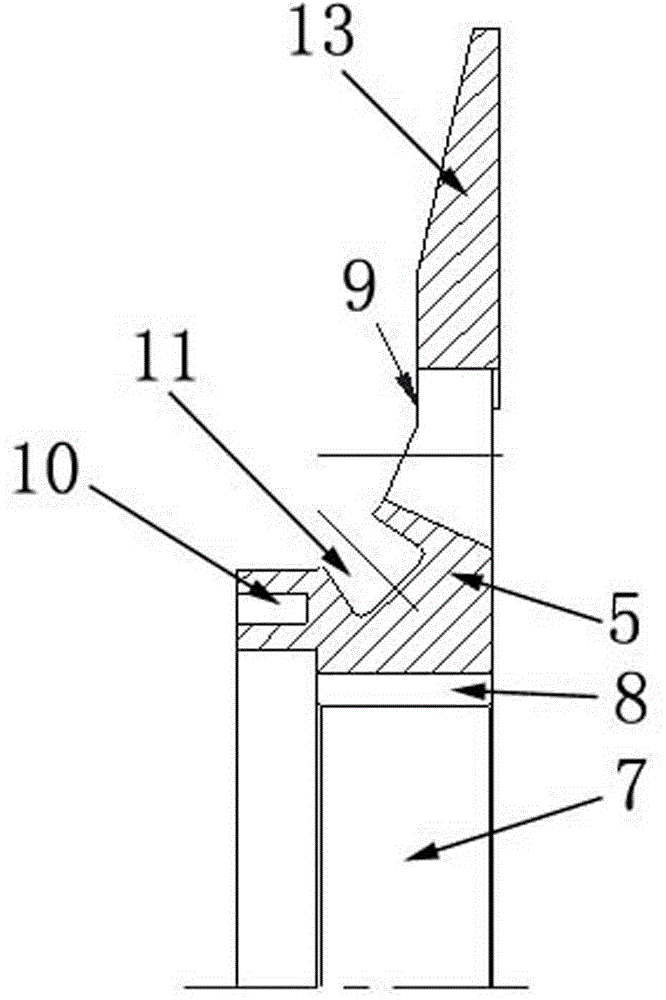

[0024] like figure 1 , 3 , 4, 5, and 6, a compact rotor structure with a rotor air path, including a shaft 1, a rotor core 2, a guide bar 3, an end ring 4, a rotor pressure plate 5 at the air outlet end, and a rotor pressure plate at the air inlet end 6. The rotor core 2 is set on the rotating shaft 1 through the key 20, the guide bar 3 is inserted through the rotor core 2, and the end rings 4 are placed on both sides of the rotor core 2 and welded to the end of the guide bar 3; Both the rotor pressure plate 5 at the air-inlet end and the rotor pressure plate 6 at the air-intake end are set on the rotating shaft 1 and pressed against both sides of the rotor core 2 separately; The shaft hole 7, the upper part of the first installation shaft hole 7 is provided with a positioning keyway 8, and the outer circumference of the first installation shaft hole 7 is evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com