A kind of manufacturing method of LED integrated packaging substrate

A manufacturing method and integrated packaging technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem of high processing cost, and achieve the effects of low processing cost, good performance and high connection reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] refer to Figure 1 to Figure 10 , the manufacturing process of the LED integrated packaging substrate of this embodiment includes the following steps:

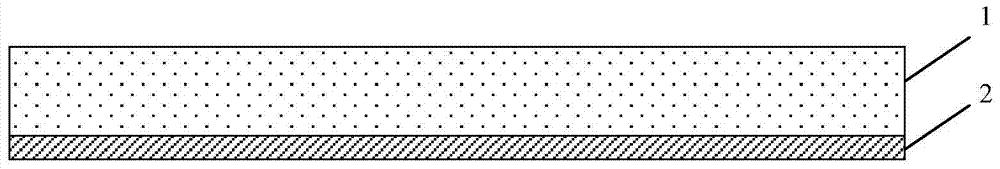

[0044] refer to figure 1 , providing a single-sided copper clad laminate, the copper clad laminate includes a resin layer 1 and a copper layer 2 below the resin layer 1 . The resin layer 1 is made of glass fiber reinforced epoxy resin, and the thickness of the copper layer 2 is above 18um, preferably 25-35um in this embodiment.

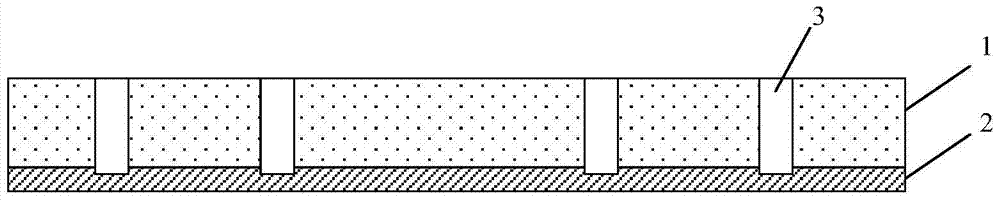

[0045] refer to figure 2 , Drill blind holes on the copper clad board to form via holes 3 . The drilling method can adopt high-precision mechanical positioning drilling or laser drilling blind holes. The via hole 3 penetrates the resin layer 1 from top to bottom in the thickness direction and penetrates into the copper layer 2 without penetrating the copper layer 2 . The position of the via hole 3 is designed according to the customer's design or the position of the LED chip package, wher...

Embodiment 2

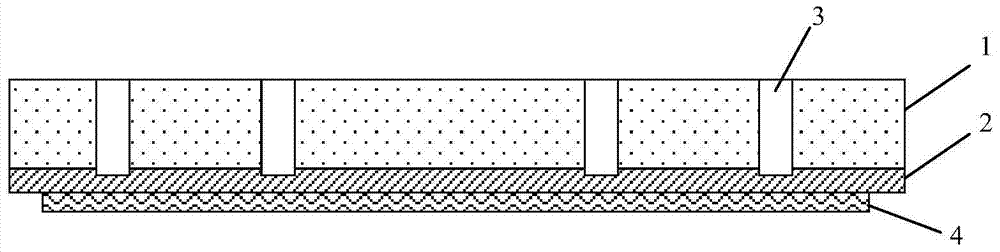

[0056] refer to Figure 1-5 and Figure 11-21 , the manufacturing process of the LED integrated packaging substrate of this embodiment includes the following steps:

[0057] Figure 1-Figure 5 The steps shown are the same as in Embodiment 1, and the structures and positional relationships of the formed resin layer 1, copper layer 2, via holes 3, copper pillars 5 and copper terminals 51 are also the same as those in Embodiment 1, and will not be repeated here.

[0058] refer to Figure 11 ,At Figure 5 A polymer conductive film layer 9 is formed on the upper surface of the structure shown, wherein the conductive film layer 9 is formed by depositing colloidal graphite.

[0059] refer to Figure 12 , micro-etching the conductive film layer 9 to remove the conductive film material attached to the surface of the copper terminal 51, so that the subsequent copper electroplating is directly bonded to the copper pillar 5, avoiding the presence of a polymer conductive film between t...

Embodiment 3

[0071] refer to Figure 1-5 and Figure 22-31 , the manufacturing process of the LED integrated packaging substrate of this embodiment includes the following steps:

[0072] Figure 1-Figure 5 The steps shown are the same as in Embodiment 1, and the structures and positional relationships of the formed resin layer 1, copper layer 2, via holes 3, copper pillars 5 and copper terminals 51 are also the same as those in Embodiment 1, and will not be repeated here.

[0073] refer to Figure 22 ,At Figure 5 A titanium-copper conductive film layer 12 is formed on the upper surface of the structure shown, wherein the conductive film layer 12 is formed by physically sputtering two layers of metal titanium and copper, specifically spraying a layer of 40-100nm thick metal titanium layer, and then spraying a layer of metal titanium layer 40-100nm thick on it. Spray a layer of 0.8-3um metal copper layer.

[0074] refer to Figure 23 , form a photosensitive anti-plating etching film 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com