Transparent conducting layer laminate plate

A transparent conductive layer and laminate technology, which is applied in the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve the problems of unsatisfactory bending deformation effect of conductive layers and substrates, complicated processes, etc., to eliminate deformation. , the effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

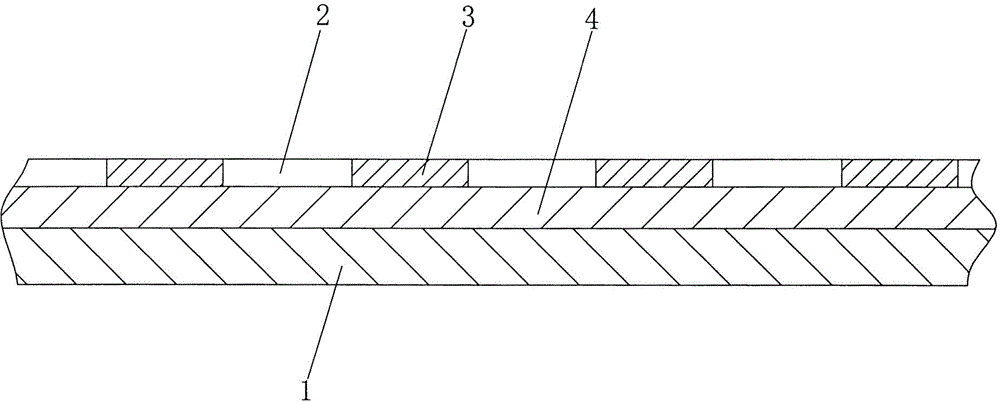

[0017] refer to figure 1 , the conductive transparent laminate body, including a transparent substrate 1 and a transparent conductive layer 2 stacked on the transparent substrate 1, the transparent conductive layer is etched into a specific pattern 3, characterized in that: the transparent substrate 1 and the transparent conductive layer A transparent buffer layer 4 with an elastic modulus of 10-30 GPa and a thickness of 1-10 μm is laid between the two.

[0018] In addition, the preferred modulus of elasticity of the transparent buffer layer 4 is 10-20 GPa, and the preferred thickness of the transparent buffer layer is 2-4 μm. The thickness of the transparent conductive layer 2 is 10-30 nm, preferably 20-25 nm. The thickness of the transparent substrate 1 is 2-300 μm, preferably 10-250 μm. The material of the transparent buffer layer 4 is acrylic resin or hardened acrylic resin, and is laid by a wet coating method of roller coating or spin coating. The material of the trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com