A Rapid Screening Method for Highly Selective Methanol-to-Olefins Catalysts

A methanol-to-olefins, high-selectivity technology, applied in the direction of using catalysis for chemical analysis, etc., to achieve the effects of less usage, avoidance of use, and short experiment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

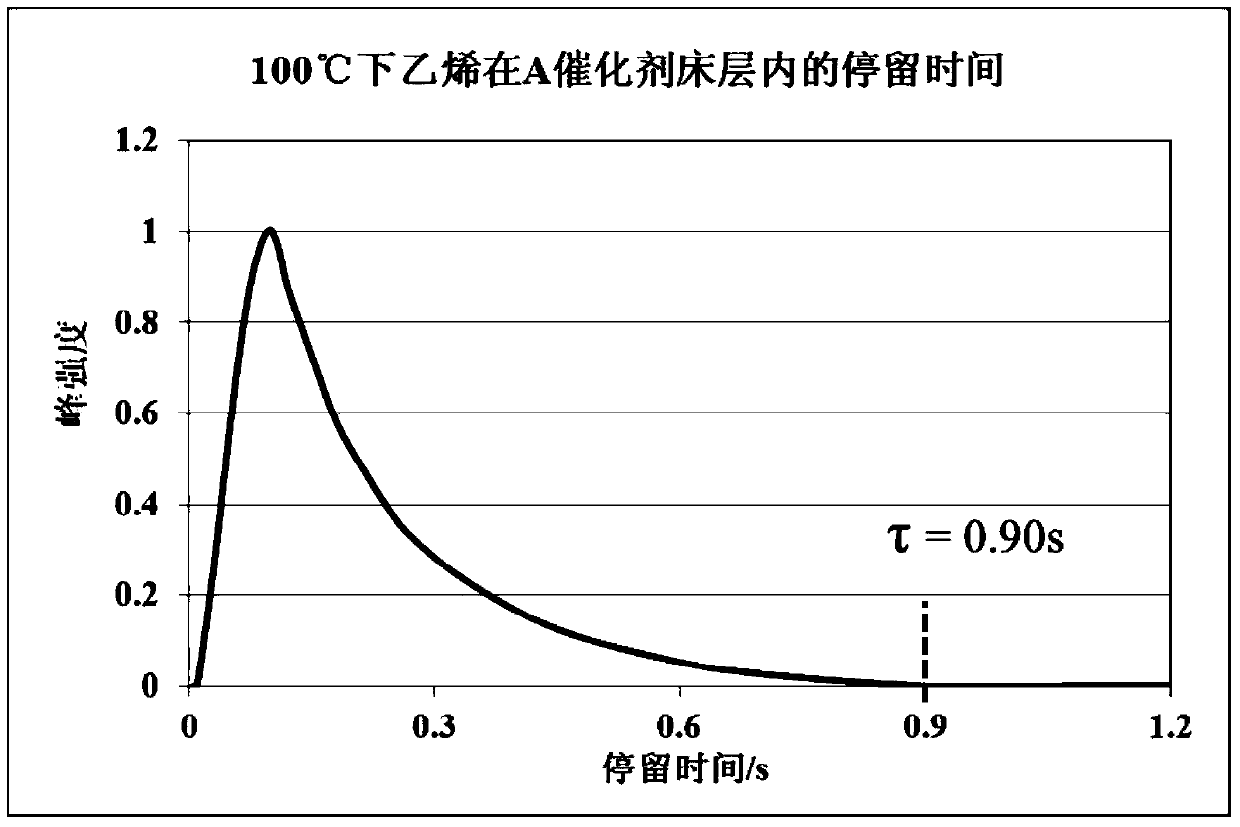

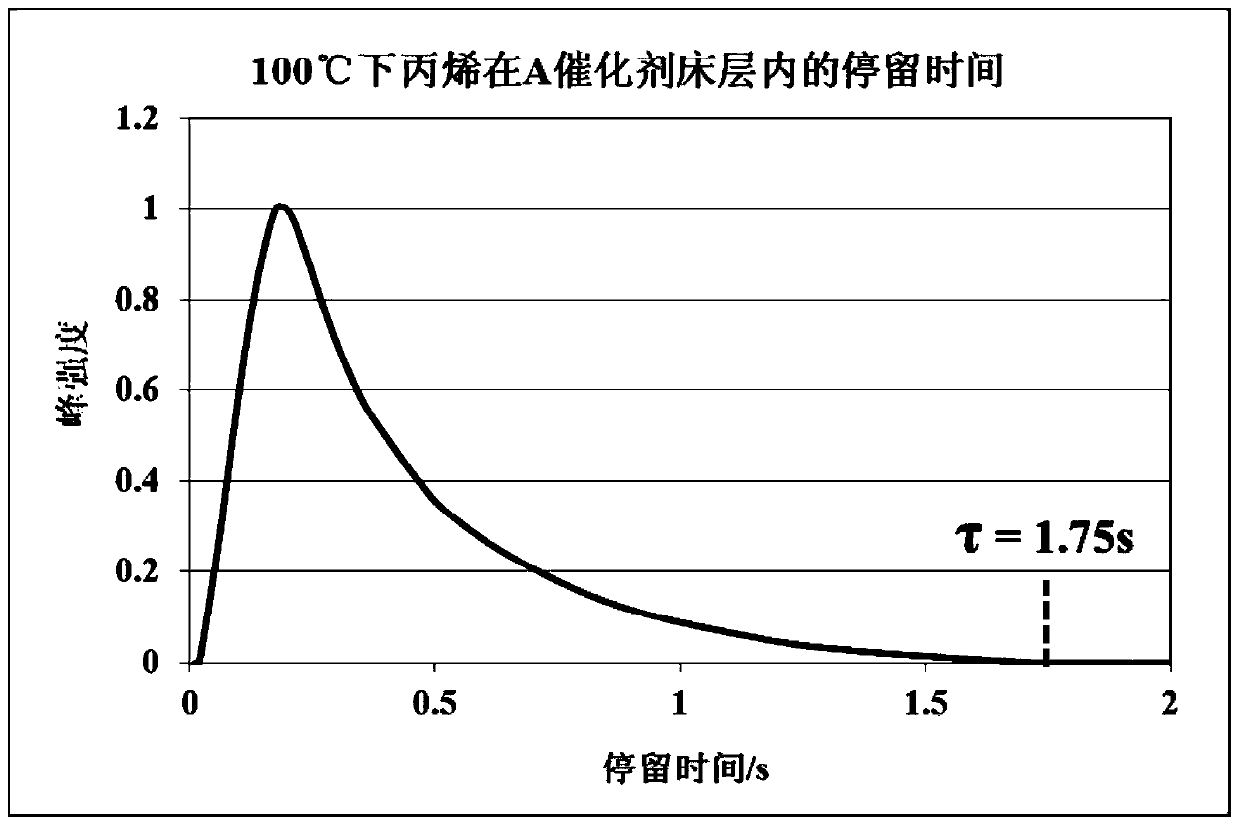

[0025] Prepare the catalyst according to the method of Example 34 in the patent No. US4,440,871, numbered as A, respectively with ethylene / helium (volume ratio is 20 / 80) and propylene / krypton gas (volume ratio is 80 / 20) As a probe molecule, a TAP experiment was performed on the catalyst.

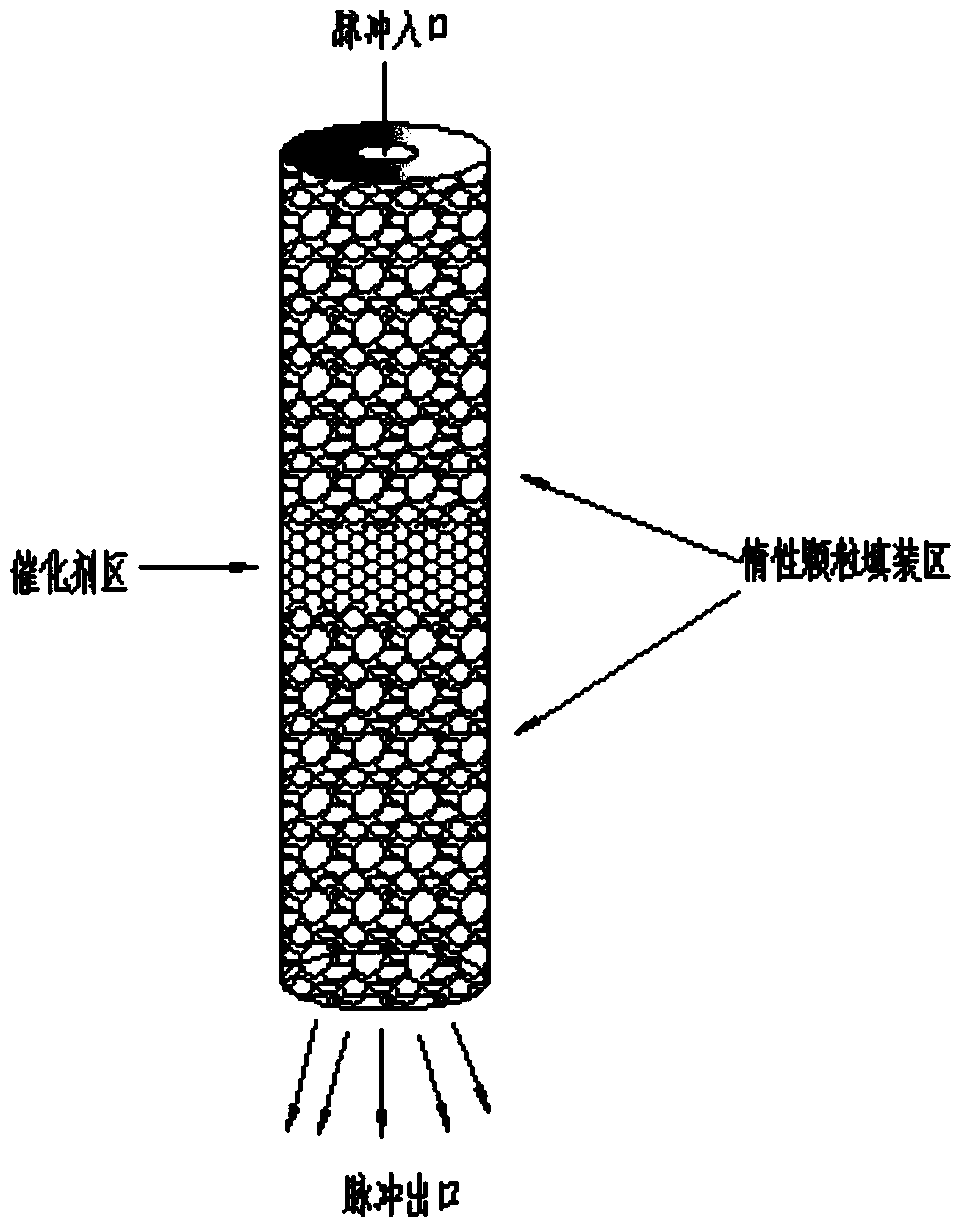

[0026] (1) Fill 8 mg of catalyst powder in the reactor, which is filled with inert silicon carbide particles with a height of 1 cm and a particle size of 210 μm;

[0027] (2), vacuumize the reactor, and then heat it up to 100°C at a rate of 10°C / min;

[0028] (3) The mixed gas ethylene / helium with a volume ratio of 20 / 80 is injected into the reactor in a pulsed manner, the pulse time is 360 μs, and a quadrupole mass spectrometer is connected to the outlet of the reactor to detect For ethylene gas, a spectrogram is formed with time as the abscissa and signal intensity as the ordinate, and the time from the peak out of the spectrum to the end of the peak is the residence time of the gas in th...

Embodiment 2

[0035] According to the method for preparing the catalyst in the patent of CN 104129800 A according to the application publication number, the numbering is denoted as B, and ethylene / neon (volume ratio is 40 / 60) and propylene / helium (volume ratio is 70 / 30) respectively ) is probe molecule, and this catalyst is carried out TAP experiment.

[0036] (1), 15 mg of catalyst powder is filled in the reactor, and its top and bottom are filled with inert silicon carbide particles with a particle size of 220 μm and a height of 2 cm;

[0037] (2), vacuumize the reactor, and then heat it up to 110°C at a rate of 15°C / min;

[0038] (3) The mixed gas ethylene / neon gas with a volume ratio of 40 / 60 is injected into the reactor in a pulsed manner, the pulse time is 360 μs, and a quadrupole mass spectrometer is connected to the outlet of the reactor to detect For ethylene gas, a spectrogram is formed with time as the abscissa and signal intensity as the ordinate, and the time from the peak out...

Embodiment 3

[0045] According to the patent application publication number CN 104326483A, the method for preparing the catalyst according to Example 4, numbering is denoted as C, respectively with ethylene / argon (volume ratio is 50 / 50) and propylene / neon gas (volume ratio is 60 / 40) ) is probe molecule, and this catalyst is carried out TAP experiment.

[0046] (1) Fill 20 mg of catalyst powder in the reactor, which is filled with inert silicon carbide particles with a height of 3 cm and a particle size of 230 μm;

[0047] (2), vacuumize the reactor, and then heat it up to 125°C at a rate of 20°C / min;

[0048] (3) Inject the mixed gas ethylene / argon with a volume ratio of 50 / 50 into the reactor in a pulsed manner, the pulse time is 360 μs, and a quadrupole mass spectrometer is connected to the outlet of the reactor to detect For ethylene gas, a spectrogram is formed with time as the abscissa and signal intensity as the ordinate, and the time from the peak out of the spectrum to the end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com