Urea pump and urea system containing same

A urea pump and urea technology, applied in the field of urea pumps and urea systems, can solve the problems of high material cost and manufacturing cost, inconvenient manufacturing and assembly, complex structure, etc., and achieve the effects of easy assembly and operation, reduced installation space, and prevention of deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

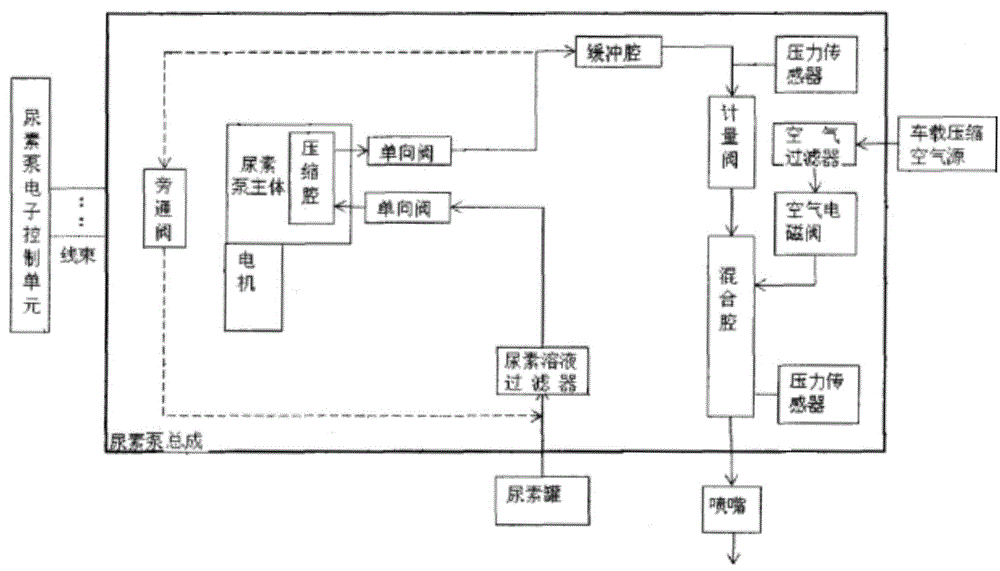

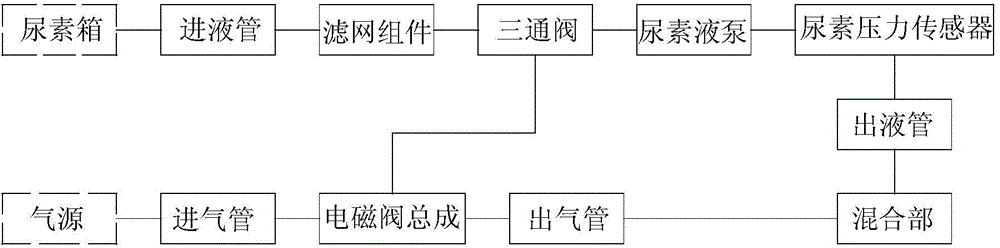

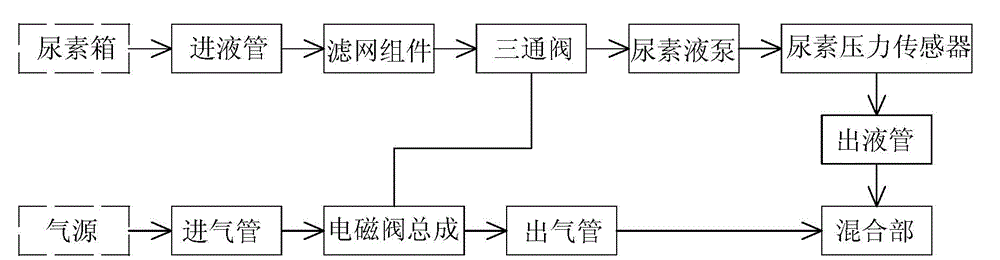

[0054] An embodiment of the present invention provides a urea pump, including: a urea branch and a gas branch, wherein the urea branch includes: a liquid inlet that provides the inlet of the urea solution, a liquid outlet that provides the outlet of the urea solution, and a The urea solution pump powered by the liquid inlet part to the liquid outlet part, and the first switch device arranged between the liquid inlet part and the liquid outlet part are used to connect the liquid inlet part to the liquid outlet part. The liquid outlets are selectively communicated; the gas branch circuit includes: an air inlet providing a gas inlet, an air outlet providing a gas outlet, and a second switch device arranged between the air inlet and the air outlet , for selectively communicating between the air inlet po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com