Three-shaft rotation base frame device in vacuum film plating cavity

A technology of vacuum coating and base transfer, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., which can solve the problems of inability to ensure that the target is facing each string of samples, high production cost, and low coating efficiency. problems, to achieve the effect of increasing the furnace charging capacity, avoiding shaking, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

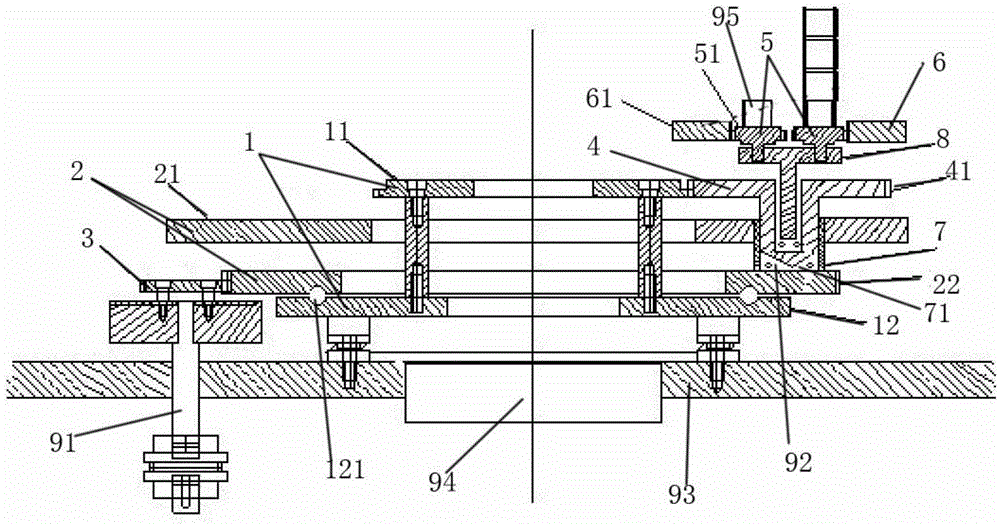

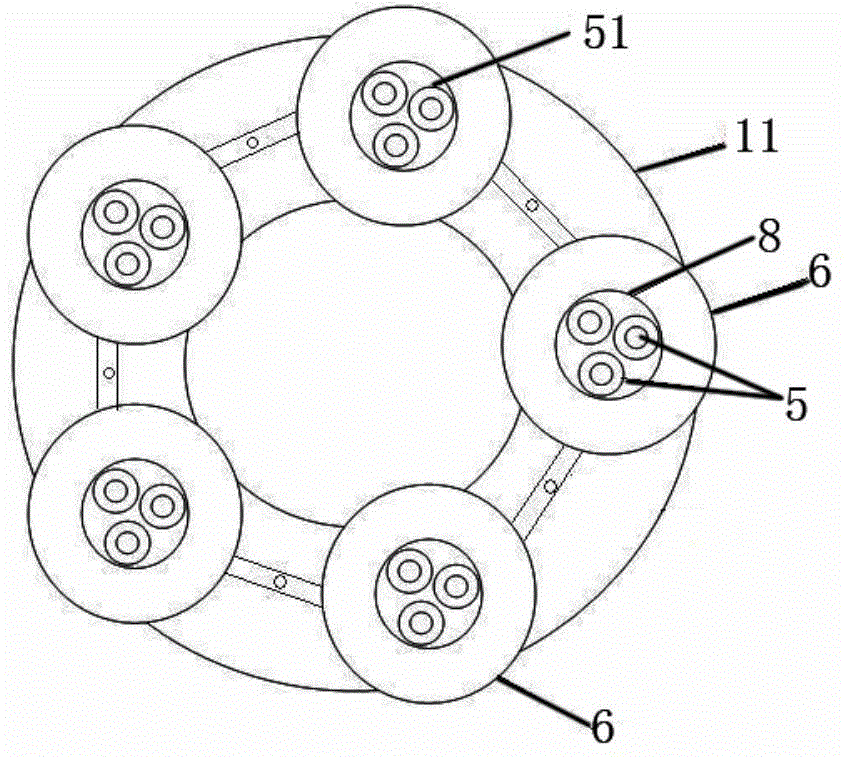

[0025] Please refer to figure 1 and figure 2 , the first gear set 1 is composed of the first upper gear 11 and the first lower gear 12, which are rigidly fixed by connecting arms to realize synchronous movement, the first lower gear 12 is fixed on the bottom plate 93 of the cavity, and its upper surface is engraved There is an annular groove 121 in which balls are placed. The second gear set 2 comprises a second upper gear 21 and a second lower gear 22, the lower surface of the second lower gear 22 is engraved with an annular groove 121 having the same diameter as the upper surface of the first lower gear 12, and the above two grooves 121 The second lower gear 22 can be placed on the first lower gear 12 by coincidence with the balls. There are five sleeve placement holes 71 evenly distributed on the upper surface of the second upper gear 21. The placement holes 71 and the second lower gear 22 A sleeve 7 as the first transmission part is fixed between them, and the second up...

Embodiment 2

[0028] The difference between this embodiment and the above-mentioned embodiment is that: the upper surface of the second upper gear 21 is evenly distributed with 8 placement holes 71, and the surface of the disc 8 is evenly distributed with 5 solid holes, and the furnace loading capacity is 40 strings, and the two-axis rotary base Compared with the 8-string furnace loading capacity of the rack, it has increased by 5 times.

Embodiment 3

[0030] The difference between this embodiment and the above-mentioned embodiment is that: there are 3 placement holes evenly distributed on the upper surface of the second upper gear 21, 4 solid holes are evenly distributed on the surface of the disc 8, and the furnace loading capacity is 12 strings, and the two-axis rotary base frame Compared with the 3-string furnace, the amount of furnace loading has increased by 4 times.

[0031] The motion principle and process created by the present invention are: when the motor 92 controls the rotation of the third gear 3, the third gear 3 drives the second lower gear 21 circumscribed therewith to rotate around the central axis 94 of the cavity. The second lower gear 22 is rigidly connected by the sleeve 7, so the fourth gear 41, disc 8, fifth gear 51, and sixth gear 61 placed in the sleeve 7 all surround the cavity with the second lower gear 22 The central axis 94 rotates, and since the sample to be coated 95 is fixed on the fifth gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com