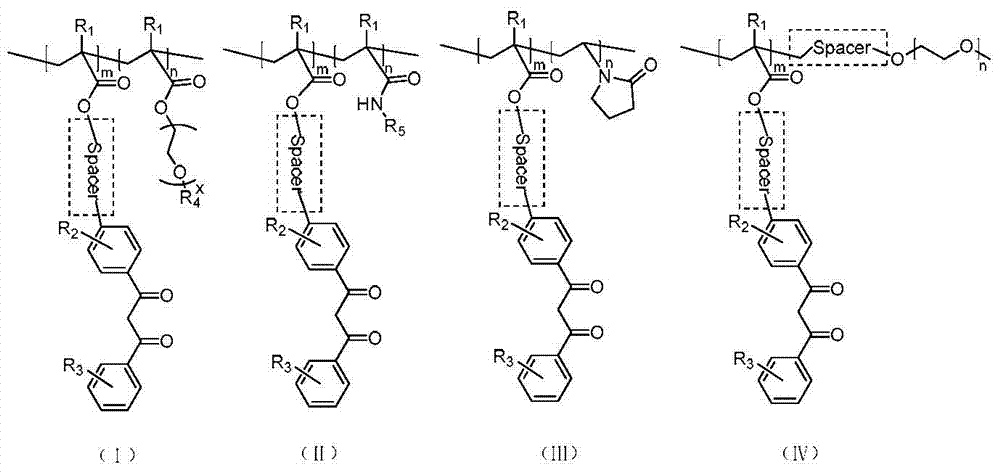

Amphiphilic block copolymer and nanoparticles comprising the same, preparation method and application thereof

A technology of amphiphilic blocks and nanoparticles, which is applied in biochemical equipment and methods, measurement/inspection of microorganisms, preparations for in vivo tests, etc., can solve problems such as short residence time, achieve narrow emission peaks, and process Simple and efficient, long fluorescence lifetime effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 1.41g methacrylic acid-4-(3-oxo-3-phenylpropionyl)phenyl ester (DKMA) (CAS: 157174-85-1), 4.15mg chain transfer agent dithiobenzoic acid-2- Phenylpropan-2-ester (CDB) (CAS:201611-77-0), 0.826mg AIBN, 10mL anisole were added to the reaction flask, the molar ratio of DKMA, AIBN and CDB was 300:0.33:1, 70℃ After reacting for 12 hours, the precipitate was dissolved in 100 mL of ether three times to remove small monomers, and dried under vacuum to obtain polymethacrylic acid-4-(3-oxo-3-phenylpropionyl)phenyl ester (PDKMA). The yield was 50%, the degree of polymerization calculated by NMR is 152, the SEC number average molecular weight is 33.8kDa, and the molecular weight distribution is 1.28.

[0063] Add 1.810g oligoethylene glycol methacrylate (OEGMA), 0.564mg PDKMA, 1.519mg AIBN and 5mL anisole into the reaction flask. The molar ratio of PDKMA, AIBN and OEGMA is 1:0.33:130, 60℃ React for 12 hours. After the reaction is over, 200mL of ether is precipitated three times to rem...

Embodiment 2

[0072] Add 1.2g of acrylic acid-4-(3-oxo-3-phenylpropionyl)phenyl ester (DKA), 5.55mg of chain transfer agent dithiobenzoic acid-2-phenylpropan-2-ester (CDB), Add 0.744mg AIBN and 5mL anisole into the reaction flask, the molar ratio of DKA, AIBN and CDB is 200:0.33:1, react at 70℃ for 24h, dissolve the precipitate in 200mL ether three times to remove small monomers, and dry in vacuum. Polyacrylic acid-4-(3-oxo-3-phenylpropionyl)phenyl ester (PDKA) was obtained, the yield was 20%, the degree of polymerization calculated by NMR was 51, the SEC number average molecular weight was 15.8kDa, and the molecular weight distribution was 1.30 .

[0073] Add 0.8g oligoethylene glycol methacrylate (OEGMA), 0.24g PDKA, 0.866mg AIBN and 5mL anisole into the reaction flask, the molar ratio of PDKA, AIBN and OEGMA is 1:0.33:100, 60℃ React for 18 hours. After the reaction is over, 200 mL of ether is precipitated three times to remove the monomer, and dried under vacuum to obtain polyacrylic acid-...

Embodiment 3

[0075] 1.45g methacrylic acid-4-(3-oxo-3-phenylpropionyl)phenyl ester (DKMA), 4.15mg chain transfer agent dithiobenzoic acid-2-phenylpropan-2-ester (CDB ), 0.826mg AIBN, 10mL anisole were added to the reaction flask, the molar ratio of DKMA, AIBN and CDB was 310:0.33:1, reacted at 70℃ for 12h, dissolved and precipitated in 300mL ether three times to remove small monomers, After vacuum drying, polymethacrylic acid-4-(3-oxo-3-phenylpropionyl)phenyl ester (PDKMA) was obtained, the yield was 53%, the degree of polymerization calculated by nuclear magnetic field was 168, and the SEC number average molecular weight was 34.8kDa. The molecular weight distribution is 1.28.

[0076] Add 0.52g N-isopropylacrylamide (NIPAM), 0.373g PDKMA, 1.519mg AIBN and 5mL anisole into the reaction flask, the molar ratio of PDKMA, AIBN and NIPAM is 1:0.33:728, react at 60℃ 8h, after the completion of the reaction, 200mL of ether was precipitated three times to remove the monomers, and dried under vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com