Coproduction method and coproduction system of glycine and iminodiacetic acid

A technology of iminodiacetic acid and iminodiacetonitrile, which is applied in the co-production method of glycine and iminodiacetic acid and its co-production system field, can solve the problem of increasing the production cost of iminodiacetonitrile, environmental pollution, and inability to be effectively utilized and other issues, to achieve the effect of low production cost, simple industrial implementation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

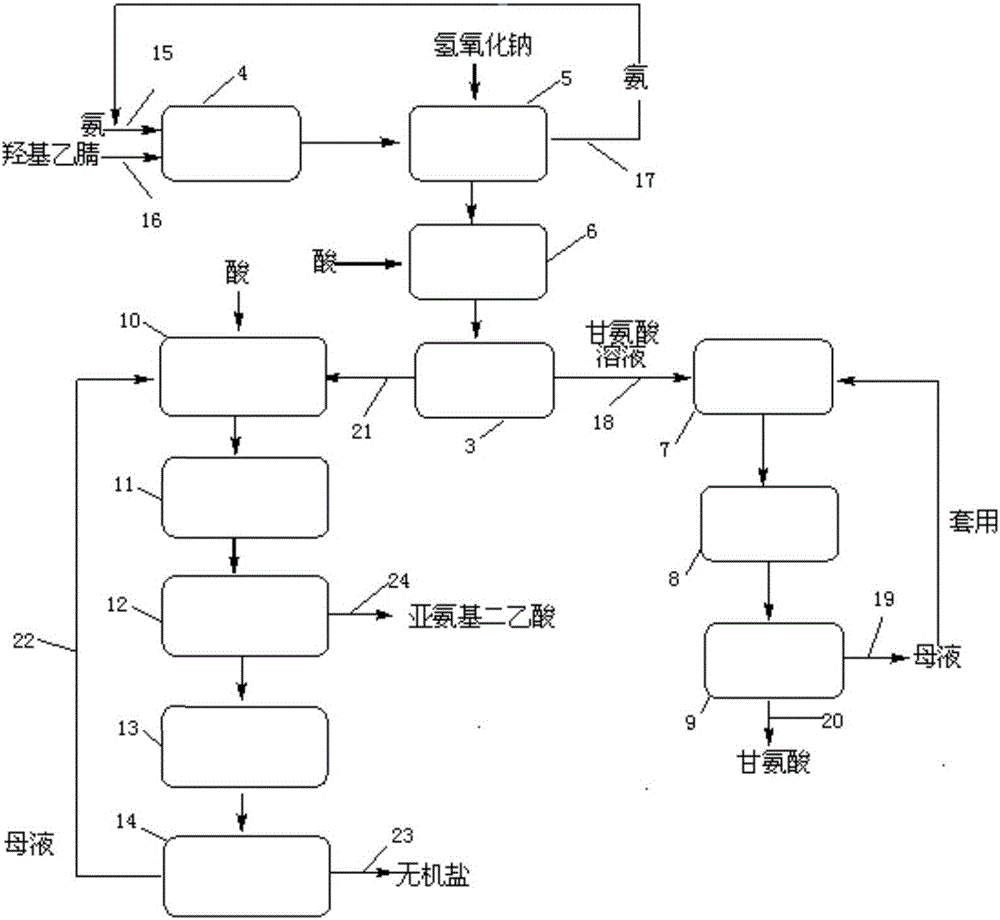

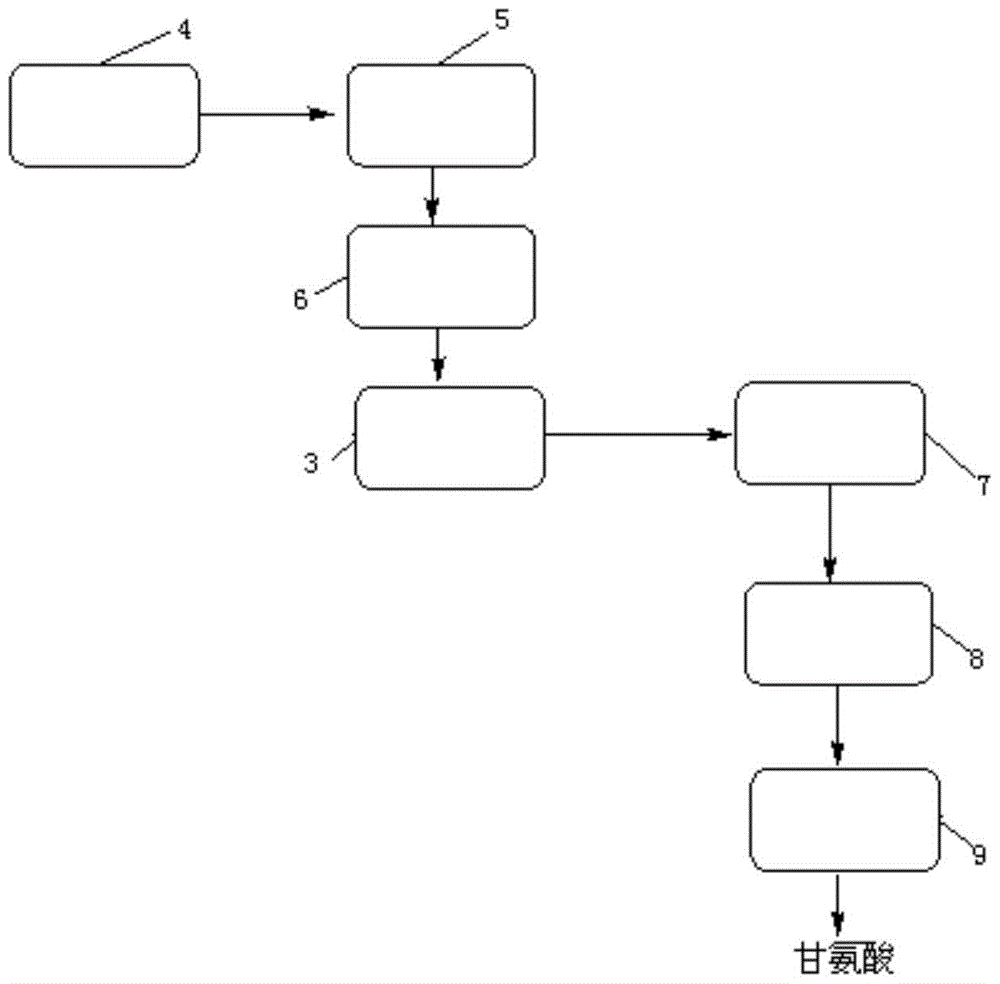

[0050] Coproduction of embodiment 1 glycine and iminodiacetic acid

[0051] Follow the steps below to produce:

[0052] (1) Take the mixture containing aminoacetonitrile and iminodiacetonitrile, alkali hydrolyze with sodium hydroxide solution, obtain the mixed solution containing sodium glycinate and disodium iminodiacetate, its composition is as follows: about 12% sodium glycinate, about 2% sodium iminodiacetic acid, about 1% sodium hydroxide. Using sulfuric acid to adjust the pH of the mixed solution to 5±0.2, during which the temperature of the reaction solution is controlled not to exceed 100°C to obtain a mixed solution containing glycine, monosodium iminodiacetic acid and sodium sulfate;

[0053] (2) Separation of glycine: Cool the mixed solution containing glycine, monosodium iminodiacetic acid and sodium sulfate obtained in step (1) to 50°C, and use a continuous chromatographic separation system filled with sodium resin to separate to obtain glycine solution and a mi...

Embodiment 2

[0055] Coproduction of embodiment 2 glycine and iminodiacetic acid (with hydroxyacetonitrile and ammonia as starting raw materials)

[0056] Follow the steps below to produce:

[0057] (1) Ammonification: Mix hydroxyacetonitrile 543.0g (42%, 4.0mol) and ammonia water 544g (25%, 8.0mol), pump them into a tubular reactor, and carry out ammoniation at a temperature of 100-103°C. reaction, the reaction time was 7 minutes by controlling the flow rate to obtain a mixed solution containing aminoacetonitrile and iminodiacetonitrile;

[0058] (2) Alkaline hydrolysis: add 351.8g sodium hydroxide solution (50%, 4.4mol) in advance in alkaline hydrolysis reactor, collect aminoacetonitrile and iminodiacetonitrile at the outlet of tubular reactor with alkaline hydrolysis reactor Mix the solution, and the reaction liquid entering the alkaline hydrolysis reactor immediately undergoes alkaline hydrolysis reaction at a temperature of 80-85°C, recovers the ammonia present in the reaction system ...

Embodiment 3

[0063] The cyclic coproduction of embodiment 3 glycine and iminodiacetic acid (with hydroxyacetonitrile and ammonia as starting materials)

[0064] The cyclic coproduction of glycine and iminodiacetic acid follows the attached figure 1 Proceed as shown in the flowchart.

[0065] first round:

[0066](1) Ammonification: Mix hydroxyacetonitrile 543.0g (42%, 4.0mol) and ammonia water 544g (25%, 8.0mol), pump them into a tubular reactor, and carry out ammoniation at a temperature of 100-103°C. reaction, the reaction time was 7 minutes by controlling the flow rate to obtain a mixed solution containing aminoacetonitrile and iminodiacetonitrile;

[0067] (2) Alkaline hydrolysis: add 351.8g sodium hydroxide solution (50%, 4.4mol) in advance in alkaline hydrolysis reactor, collect aminoacetonitrile and iminodiacetonitrile at the outlet of tubular reactor with alkaline hydrolysis reactor The mixed solution, the reaction solution entering the alkaline hydrolysis reactor immediately un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com