Preparation method for refining terephthalic acid

A technology of terephthalic acid and a manufacturing method, which is applied in the directions of oxidative preparation of carboxylic acid, chemical instruments and methods, preparation of organic compounds, etc. Equipment and machine costs, maintenance and management costs, and the effect of reducing the frequency of failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

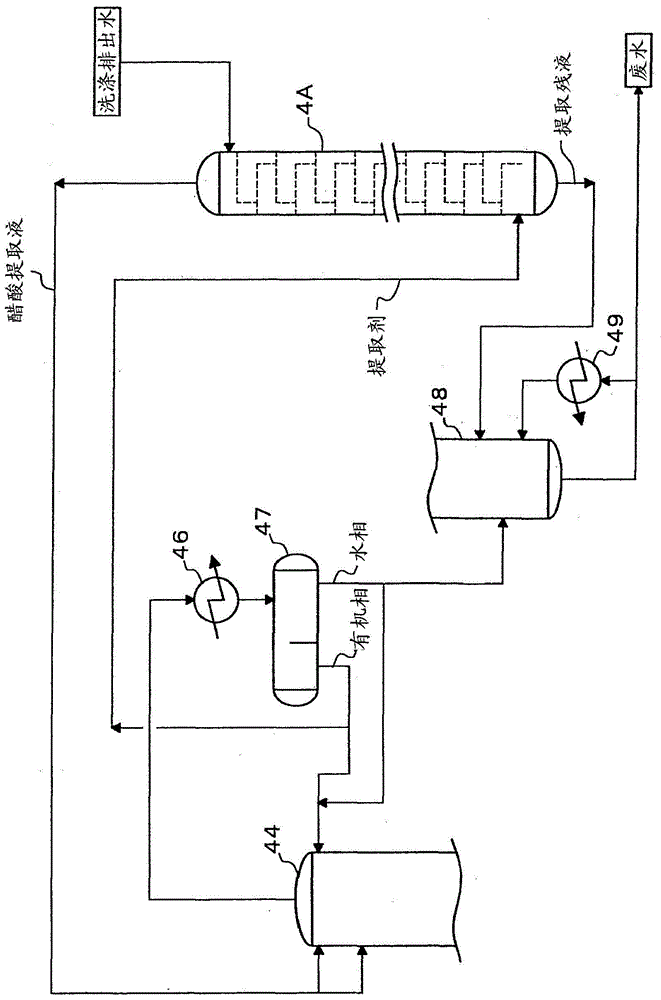

[0141] Use a perforated plate extraction tower with an inner diameter of 60 mm, a height of about 2600 mm, and a plate count of 25 plates (a perforated plate tower with a perforated plate with a stainless steel downcomer sandwiched between a short pipe (90 mm) with an acrylic flange) , 15% by mass aqueous acetic acid solution was supplied from the top of the tower at a rate of 170 g / min. On the other hand, butyl acetate as an extractant was continuously supplied at a ratio of 526 g / min (3.1 times by mass as a solvent ratio to the aqueous acetic acid solution) from the bottom of the column (countercurrent extraction). Then, the acetic acid extraction solution was discharged from the top of the tower, and the extraction raffinate was discharged from the bottom of the tower, and a continuous extraction test of acetic acid using butyl acetate was implemented. In addition, the average temperature of the extraction tower in which the test was carried out was about 35°C.

[0142] Th...

Embodiment 3

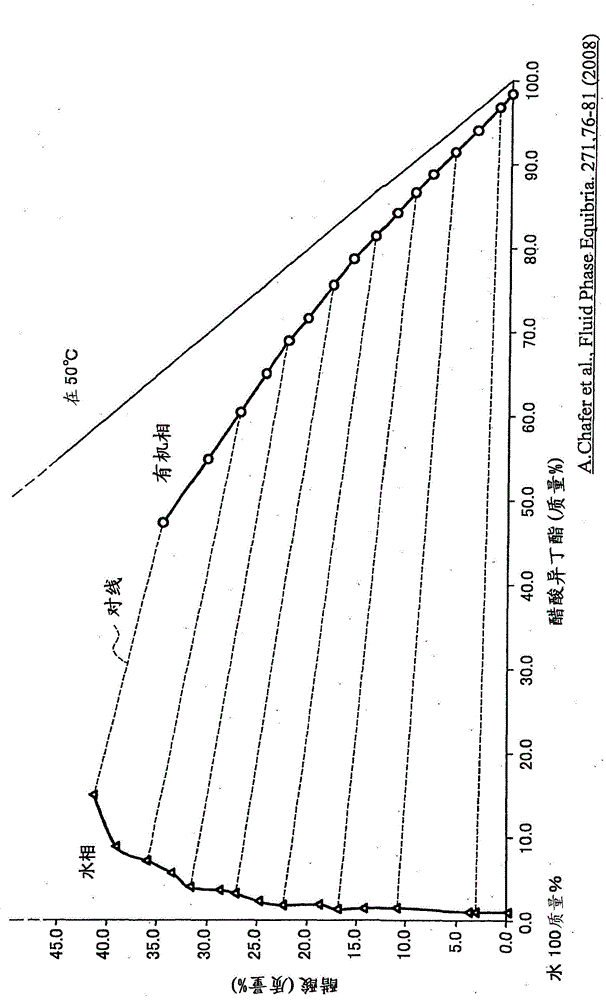

[0147] Use the perforated plate type extraction tower of embodiment 2, the 10 mass % acetic acid aqueous solution is from tower top with the ratio of 100g / minute, in addition, as the isobutyl acetate of extractant with the ratio of 300g / minute (as the solvent with respect to acetic acid aqueous solution The ratio is 3 mass times) to be supplied continuously from the bottom of the tower. Then, in the same manner as in Example 2, a continuous extraction test of acetic acid was implemented. In addition, the average temperature of the extraction tower in which the test was carried out was about 35°C. The results are shown in Table 4.

[0148] 【Table 4】

[0149]

[0150] As shown in Table 4, the acetic acid content contained in the acetic acid extract was 3.1% by mass. From this result, it was found that the extraction rate of acetic acid was about 97%. In addition, the acetic acid content of the extraction raffinate was 0.3% by mass, and it became clear that most o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com